Infiniti FX35 / FX45. Manual - part 271

CO-14

< SERVICE INFORMATION >

[VQ35DE]

RADIATOR

4.

Remove reservoir tank and reservoir tank bracket.

5.

Disconnect A/T fluid cooler hoses from radiator.

• Install blind plug to avoid leakage of A/T fluid.

6.

Removal radiator hoses (upper and lower) and reservoir tank hose.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

7.

Remove radiator cooling fan assembly. Refer to

.

8.

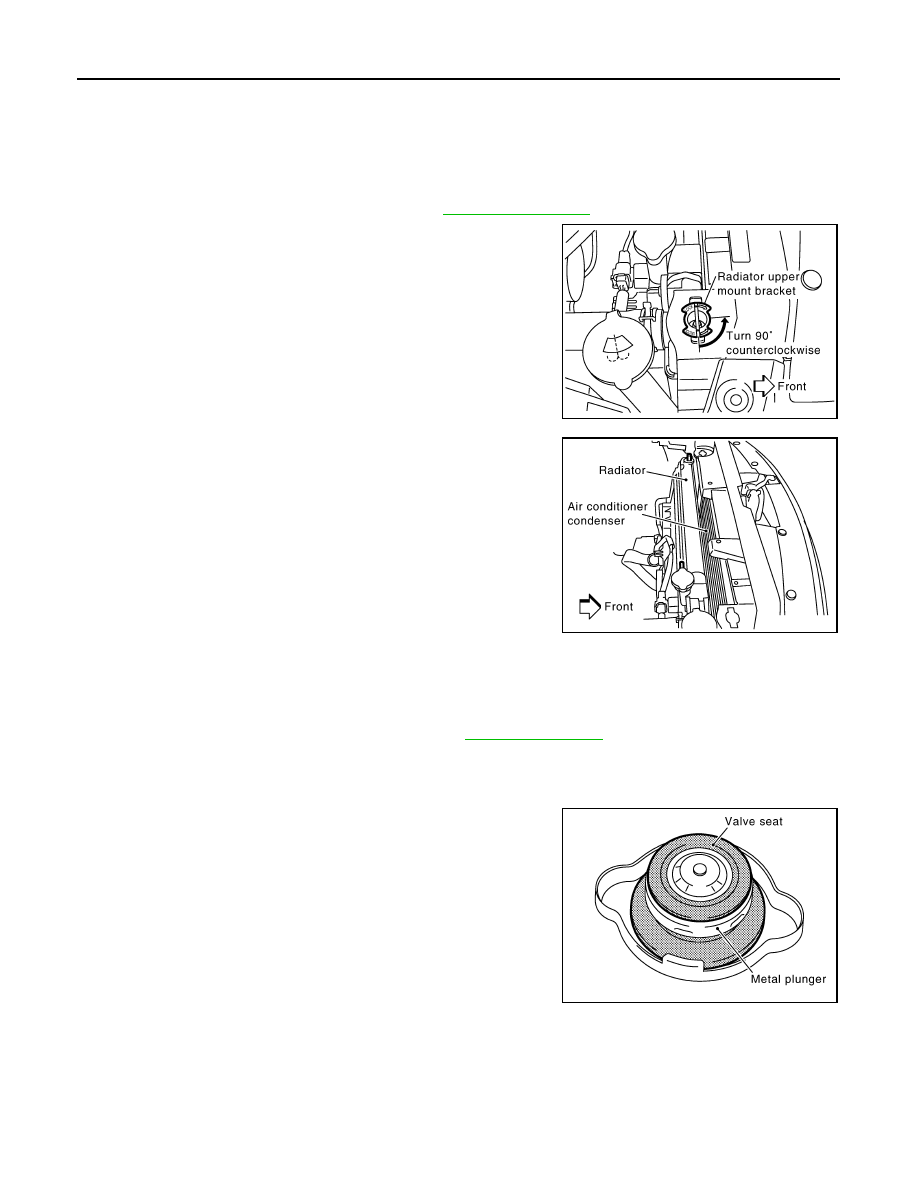

Rotate two radiator upper mount brackets 90 degrees in the

direction shown in the figure, and remove them.

9.

Lift up and remove radiator.

CAUTION:

Do not damage or scratch A/C condenser and radiator core

when removing.

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Check for leaks of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to

.

• Start and warm up the engine. Visually make sure that there is no leaks of engine coolant and A/T fluid.

Checking Radiator Cap

INFOID:0000000001325849

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

SBIA0447E

SBIA0448E

PBIC2816E