Infiniti FX35 / FX45. Manual - part 249

BRAKE MASTER CYLINDER

BR-13

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

5.

Remove master cylinder assembly mounting nut, remove master cylinder assembly from the vehicle.

Refer to

BR-14, "Removal and Installation"

.

INSTALLATION

CAUTION:

• Refill with new brake fluid “DOT3”.

• Do not reuse drained brake fluid.

1.

Install in the reverse order of removal, and tighten mounting nuts to the specified torque. Refer to

.

2.

Refill brake fluid and bleed air. Refer to

Disassembly and Assembly

INFOID:0000000001327620

DISASSEMBLY

CAUTION:

• Master cylinder can not be disassembled.

• Remove reservoir tank only when absolutely necessary.

1.

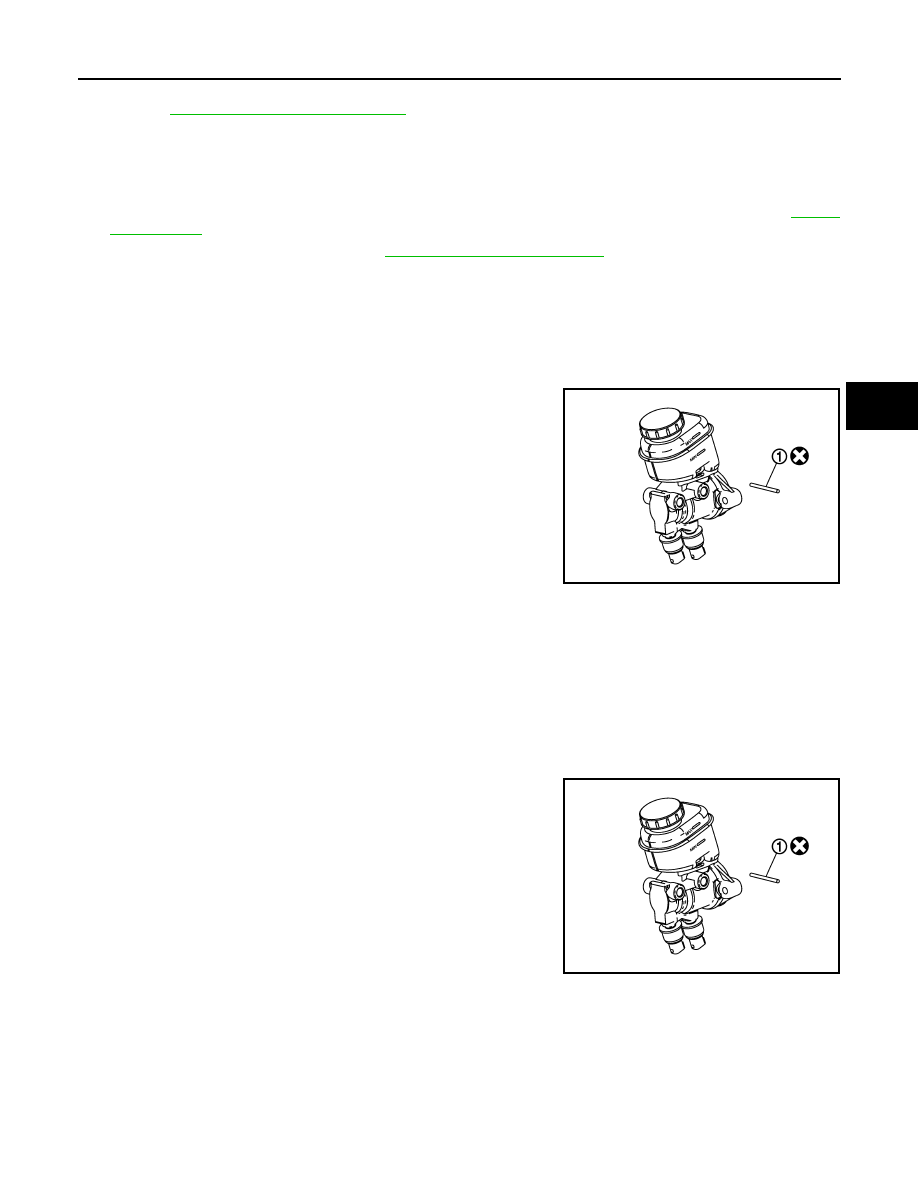

Remove pin (1).

2.

Remove reservoir tank and grommet from master cylinder

assembly.

ASSEMBLY

CAUTION:

• Do not use mineral oil such as kerosene, gasoline during the cleaning and assembly process.

• Do not drop parts. If a part is dropped, do not use it.

1.

Apply brake fluid grommet and attach to master cylinder assembly.

CAUTION:

Do not reuse grommet.

Do not reuse pin.

2.

Install reservoir tank onto master cylinder assembly.

3.

Install pin (1).

PFIA0816E

PFIA0816E