Infiniti FX35 / FX45. Manual - part 21

AT-12

< SERVICE INFORMATION >

A/T FLUID

When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

e.

Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

To check A/T fluid level, insert the A/T fluid level gauge until the cap contacts the end of the A/T

fluid charging pipe, with the A/T fluid level gauge reversed from the normal attachment conditions.

f.

Remove A/T fluid level gauge and note reading. If reading is at low side of range, add ATF to the A/T fluid

charging pipe.

CAUTION:

Do not overfill.

5.

Drive vehicle for approximately 5 minutes in urban areas.

6.

Make the A/T fluid temperature approximately 65

°

C (149

°

F).

NOTE:

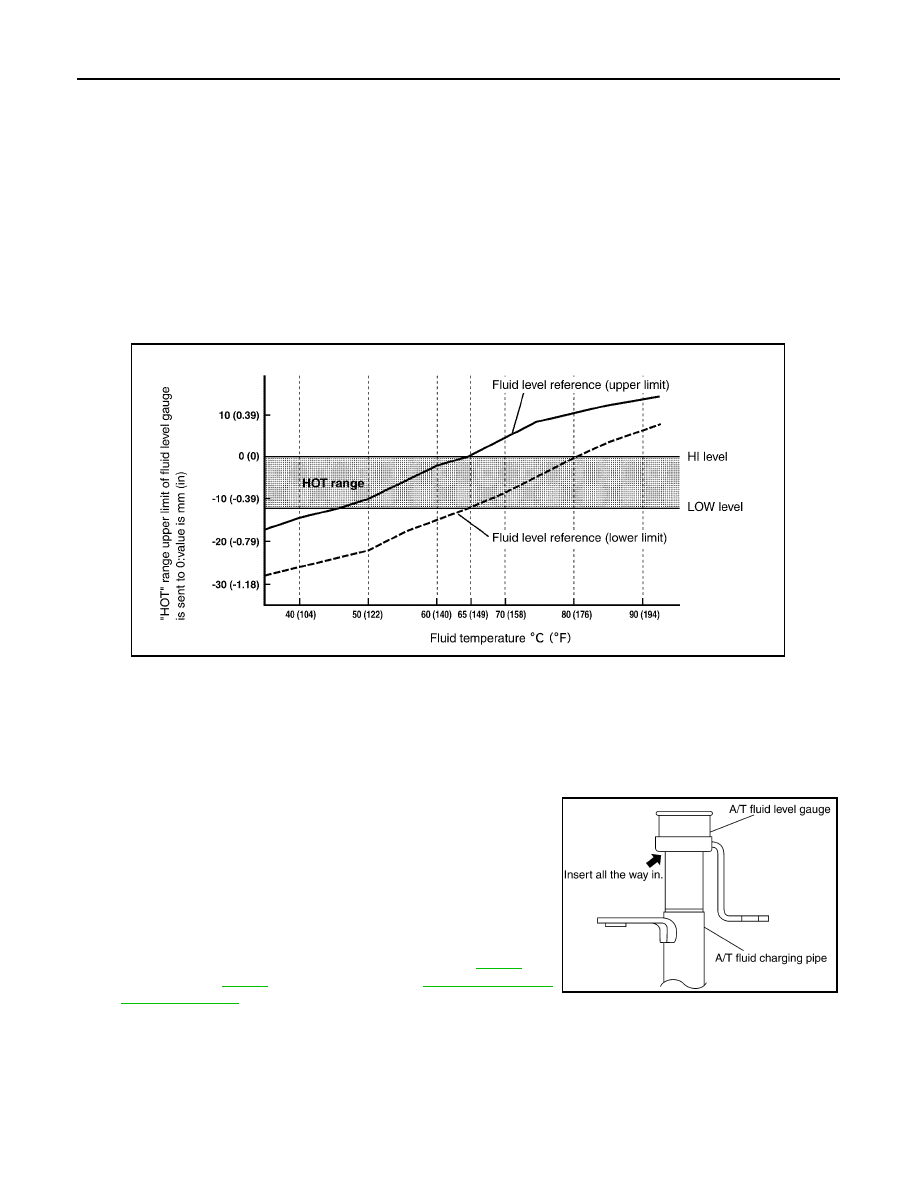

A/T fluid level will be greatly affected by temperature as shown in figure. Therefore, be certain to

perform operation while checking data with CONSULT-III.

a.

Connect CONSULT-III to data link connector.

b.

Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

c.

Read out the value of “ATF TEMP 1”.

7.

Recheck A/T fluid level at A/T fluid temperatures of approximately 65

°

C (149

°

F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

• When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

• To check A/T fluid level, insert the A/T fluid level gauge

until the cap contacts the end of the A/T fluid charging

pipe, with the A/T fluid level gauge reversed from the nor-

mal attachment conditions as shown.

8.

Check A/T fluid condition.

• If ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

• If ATF contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to

VQ35DE) or

(for VK45DE) and

SLIA0016E

SCIA2899E