Infiniti FX35, FX50 (S51). Manual - part 930

EM-20

< PERIODIC MAINTENANCE >

[VQ35HR]

CAMSHAFT VALVE CLEARANCE

CAMSHAFT VALVE CLEARANCE

Inspection and Adjustment

INFOID:0000000005245121

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

In cases of removing/installing or replacing camshaft and valve-

related parts, or of unusual engine conditions due to changes in

valve clearance (found malfunctions during stating, idling or causing

noise), perform inspection as follows:

1.

Remove rocker covers (bank 1 and bank 2). Refer to

EM-50, "Removal and Installation"

2.

Measure the valve clearance as per the following:

a.

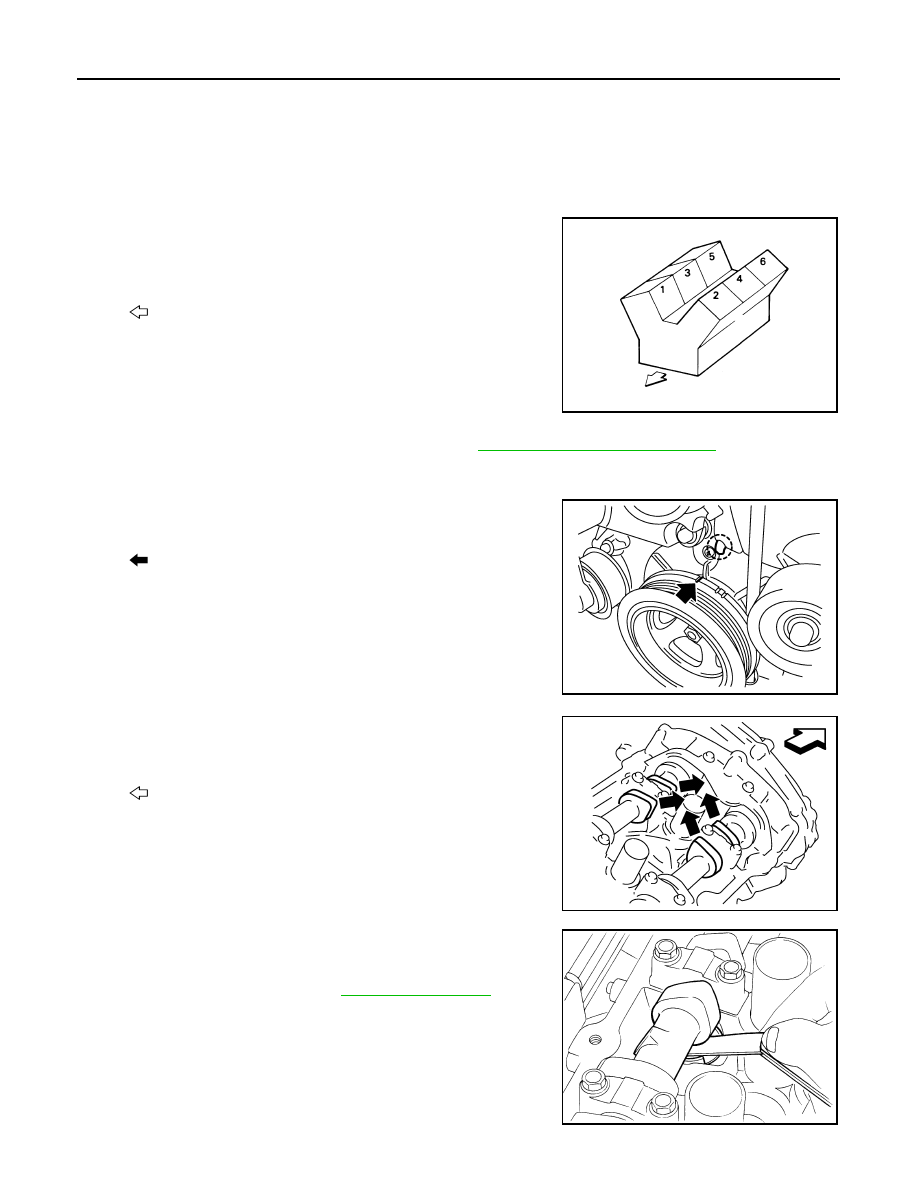

Set No. 1 cylinder at TDC of its compression stroke.

• Rotate crankshaft pulley clockwise to align timing mark

(grooved line without color) with timing indicator.

• Check that intake and exhaust cam nose on No. 1 cylinder

(engine front side of bank 1) are located as shown in the fig-

ure.

• If not, turn crankshaft one revolution (360 degrees) and align

as shown in the figure.

b.

Use a feeler gauge, measure the clearance between valve lifter

and camshaft.

: Engine front

JPBIA0164ZZ

: Timing mark (grooved line without color)

JPBIA0043ZZ

: Engine front

JPBIA0044ZZ

Valve clearance

: Refer to

.

SEM139D