Infiniti FX35, FX50 (S51). Manual - part 734

ICC BRAKE SWITCH

EC-477

< DTC/CIRCUIT DIAGNOSIS >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 3.

3.

CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-I

1.

Turn ignition switch OFF.

2.

Disconnect ICC brake switch harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between ICC brake switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 4.

4.

CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ICC brake hold relay.

3.

Turn ignition switch ON.

4.

Check the voltage between ICC brake hold relay harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

DETECT MALFUNCTIONING PART

Check the following.

• Fuse block (J/B) connector E103

• 10 A fuse (No. 3)

• Harness for open or short between ICC brake hold relay and fuse

>> Repair open circuit or short to ground in harness or connectors.

6.

CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-III

1.

Turn ignition switch OFF.

2.

Check the continuity between ICC brake switch harness connector and ICC brake hold relay harness con-

nector.

3.

Also check harness for short to ground and short to power.

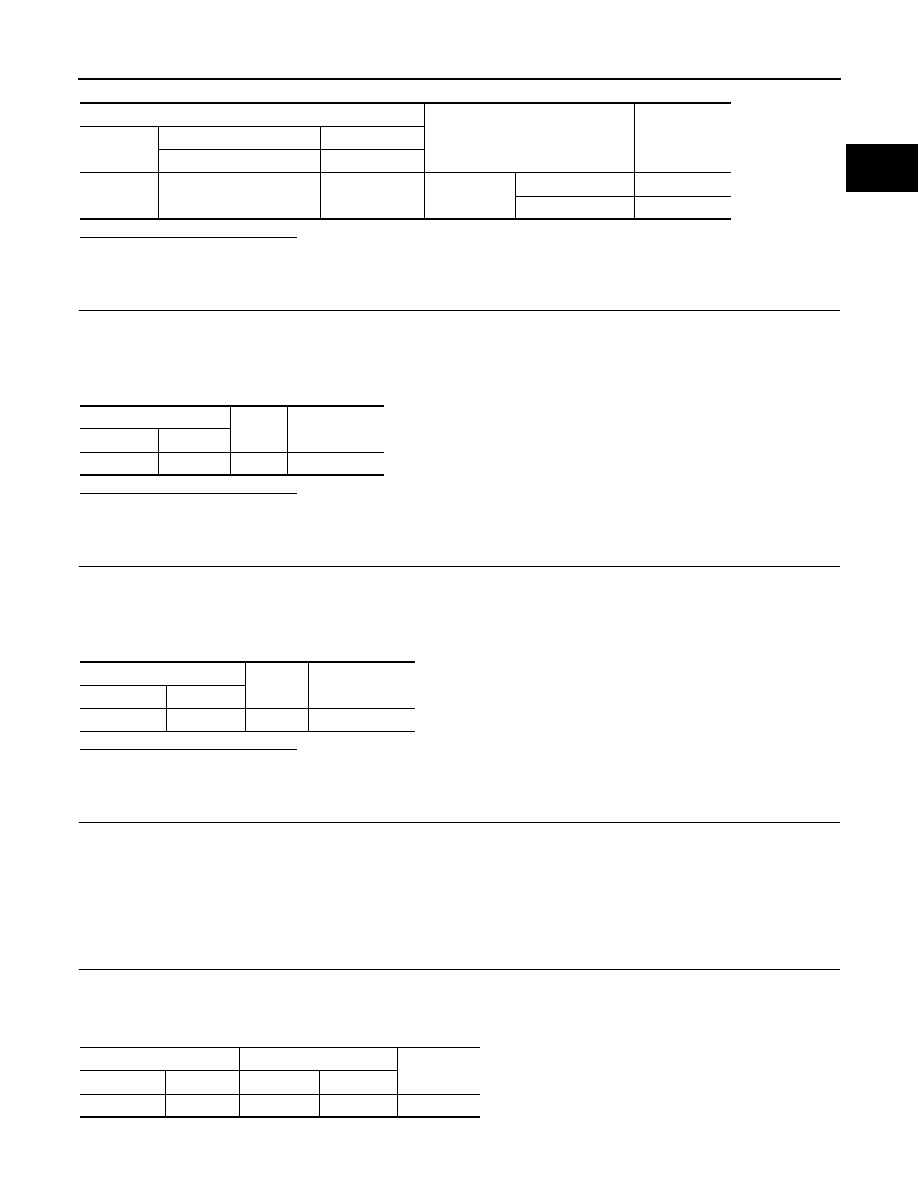

ECM

Condition

Voltage (V)

Connector

+

–

Terminal

Terminal

M107

117

(ICC brake switch signal)

128

Brake pedal

Slightly depressed

Approx. 0

Fully released

Battery voltage

ICC brake switch

Ground

Voltage

Connector

Terminal

E114

1

Ground

Battery voltage

ICC brake hold relay

Ground

Voltage

Connector

Terminal

E91

3

Ground

Battery voltage

ICC brake switch

ICC brake hold relay

Continuity

Connector

Terminal

Connector

Terminal

E114

1

E91

4

Existed