Infiniti FX35, FX50 (S51). Manual - part 696

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-325

< DTC/CIRCUIT DIAGNOSIS >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Always replace O-ring with a new one.

3.

Install a vacuum pump to EVAP control system pressure sensor.

4.

Turn ignition switch ON and check output voltage between ECM harness connector terminals under the

following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Never apply below -93.3 kPa (-0.952 kg/cm

2

, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/cm

2

,

14.69 psi).

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace EVAP control system pressure sensor

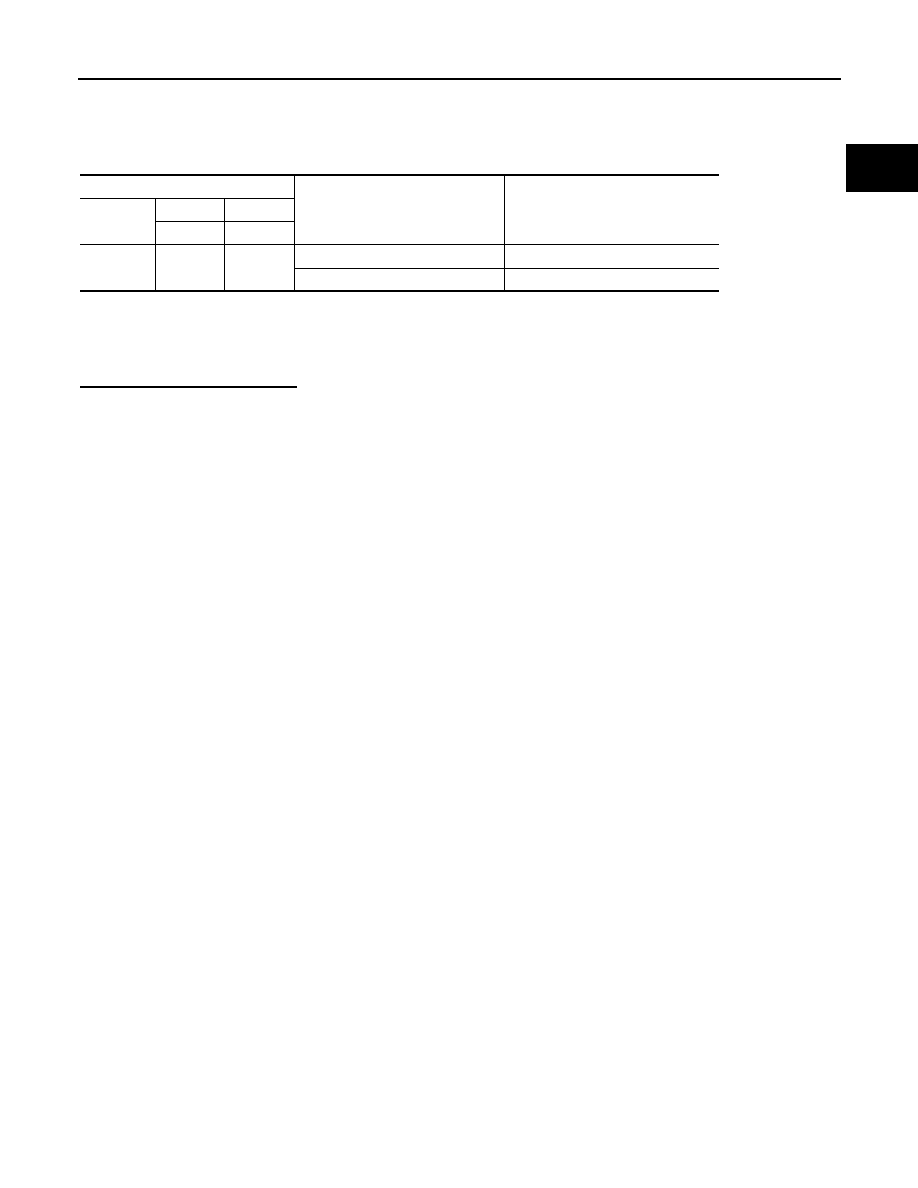

ECM

Condition

[Applied vacuum kPa (kg/cm

2

, psi)]

Voltage (V)

Connector

+

–

Terminal

Terminal

M107

102

112

Not applied

1.8 - 4.8

-26.7 (-0.272, -3.87)

2.1 to 2.5 lower than above value