Infiniti FX35, FX50 (S51). Manual - part 299

CCS-16

< BASIC INSPECTION >

[ICC (FULL SPEED RANGE)]

INSPECTION AND ADJUSTMENT

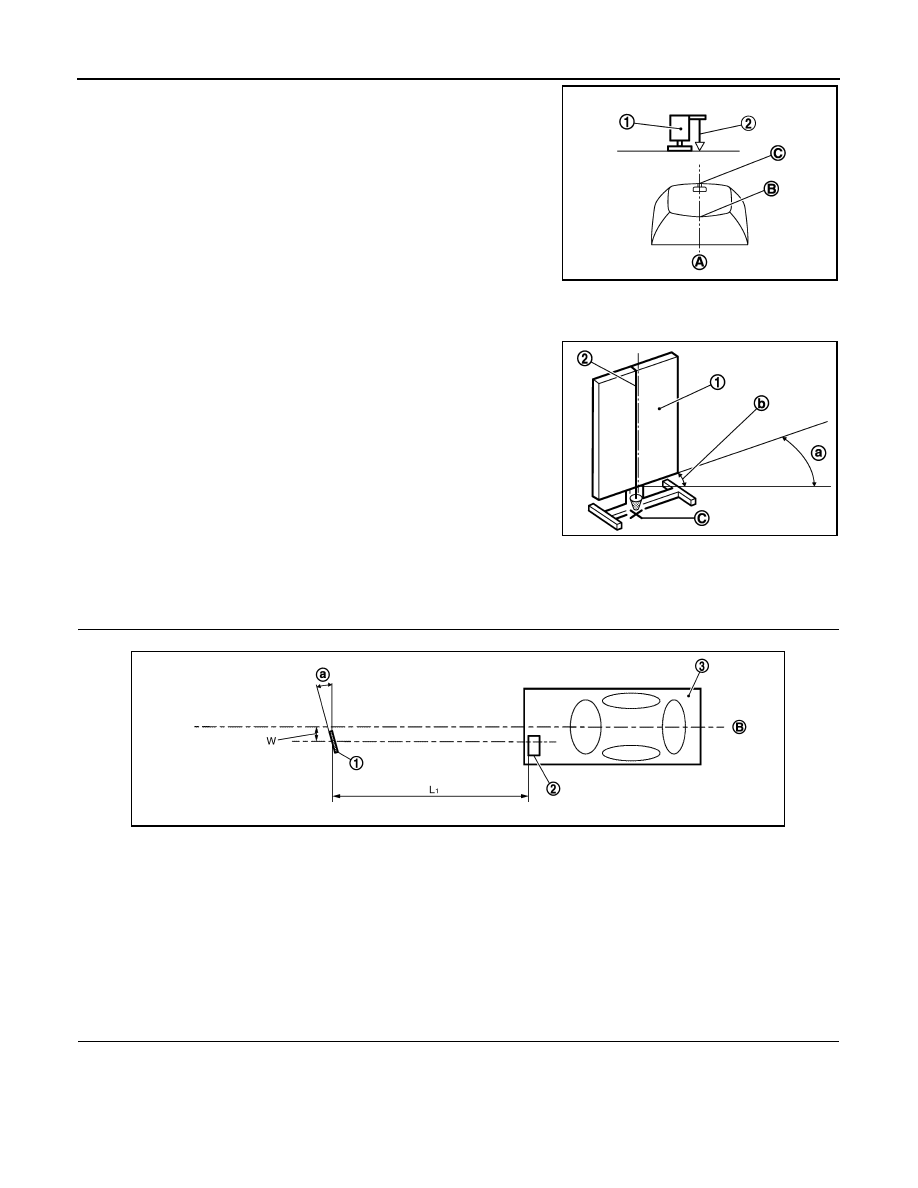

3.

Adjust the position of the ICC target board (1) so that the

extended line (A) that links the center of the rear window glass

(the center of the rear window defogger pattern) (B) and the cen-

ter of the windshield (the setting part of the room mirror) (C)

align with the weight suspended (2) from the ICC target board.

4.

Remove the thread suspended to the right side of ICC target board and suspend a thread with weight on

tip on the center of the ICC target board. Then mark the point of weight on the ground.

5.

Pivot the edge of the ICC target board 25

°

(a) to either side.

NOTE:

Approx. 90 mm (3.54 in) (b) shift rates the 25

°

(a) movement.

>> GO TO 4.

4.

CHECK THE ICC TARGET BOARD INSTALLATION POSITION

Check that the ICC target board (1) is located as shown in the figure.

NOTE:

The distance between laser beam axis and ICC target board is 4.0 m (13.0 ft).

>> GO TO 5.

5.

CHECK THE ICC TARGET BOARD INSTALLATION AREA

JSOIA0025ZZ

1

: ICC target board

2

: String with a weight

C

: ICC target board center marking point

JSOIA0026ZZ

1.

ICC target board

2.

ICC sensor integrated unit

3.

Vehicle

B.

Vehicle center

L

1

.

4.0 m (13.0 ft)

W.

315 mm (12.4 in)

a.

25

°

JSOIA0017ZZ