Content .. 1365 1366 1367 1368 ..

Infiniti FX35, FX50 (S51). Manual - part 1367

MA-32

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1.

With a dial indicator, measure propeller shaft runout at runout

measuring points by rotating final drive companion flange with

hands.

2.

If runout still exceeds specifications, separate propeller shaft at

final drive companion flange; then rotate companion flange 120,

240 degrees and install propeller shaft.

3.

Check runout again. If runout still exceeds specifications,

replace propeller shaft assembly.

4.

Check the vibration by driving vehicle.

RUNOUT MEASURING POINT

Propeller shaft runout measuring point (Point “ ”).

REAR PROPELLER SHAFT: 3F80A-1VL107

REAR PROPELLER SHAFT: 3F80A-1VL107 : Inspection

INFOID:0000000005248749

NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1.

With a dial indicator, measure propeller shaft runout at runout

measuring points by rotating final drive companion flange with

hands.

2.

If runout still exceeds specifications, separate propeller shaft at

final drive companion flange, then rotate companion flange 60,

120, 180, 240, 300 degrees and install propeller shaft.

3.

Check runout again. If runout still exceeds specifications,

replace propeller shaft assembly.

4.

Check the vibration by driving vehicle.

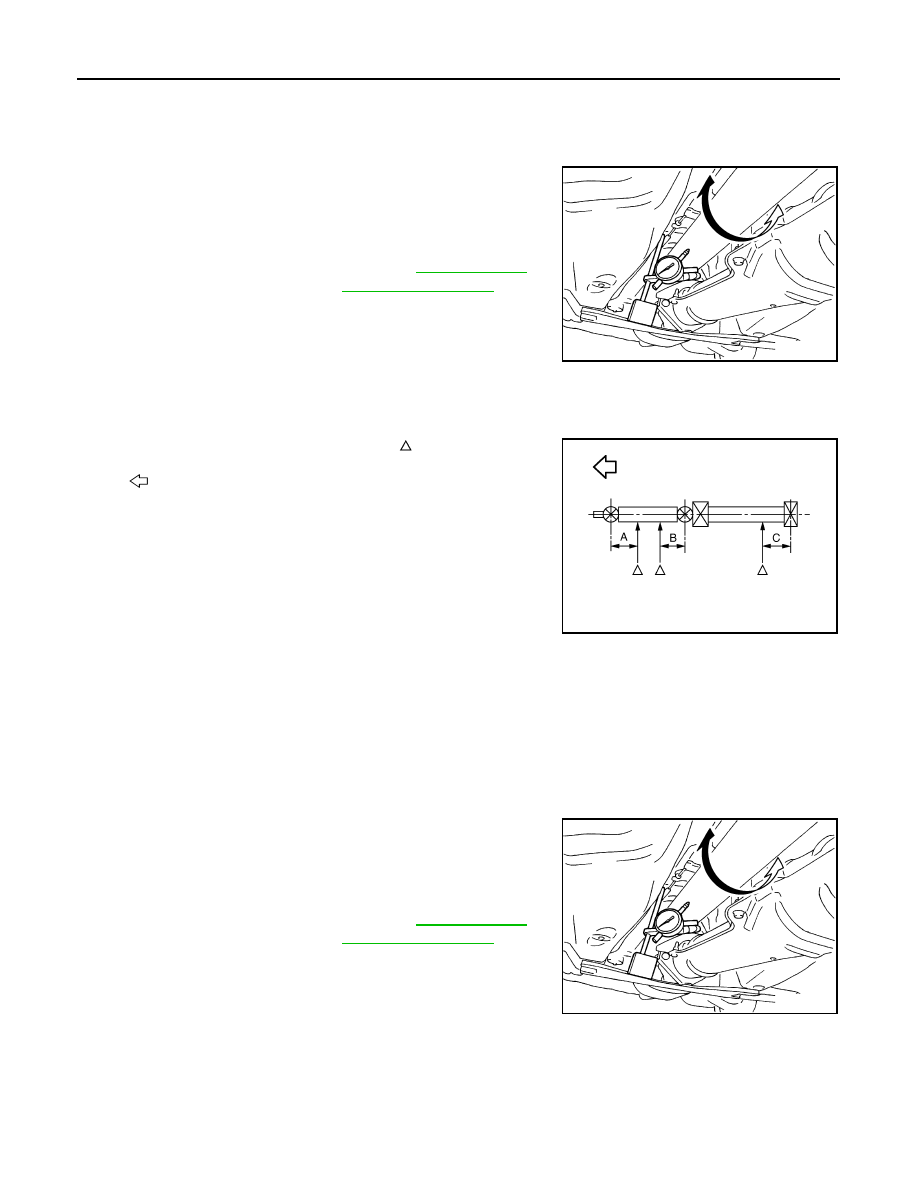

RUNOUT MEASURING POINT

Limit

Propeller shaft runout

: Refer to

.

SDIA1087E

: Vehicle front

Standard

A

: 192 mm (7.56 in)

B

: 172 mm (6.77 in)

C

: 172 mm (6.77 in)

JSDIA0169ZZ

Limit

Propeller shaft runout

: Refer to

.

SDIA1087E