Infiniti EX35. Manual - part 716

TIMING CHAIN

EM-63

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

b.

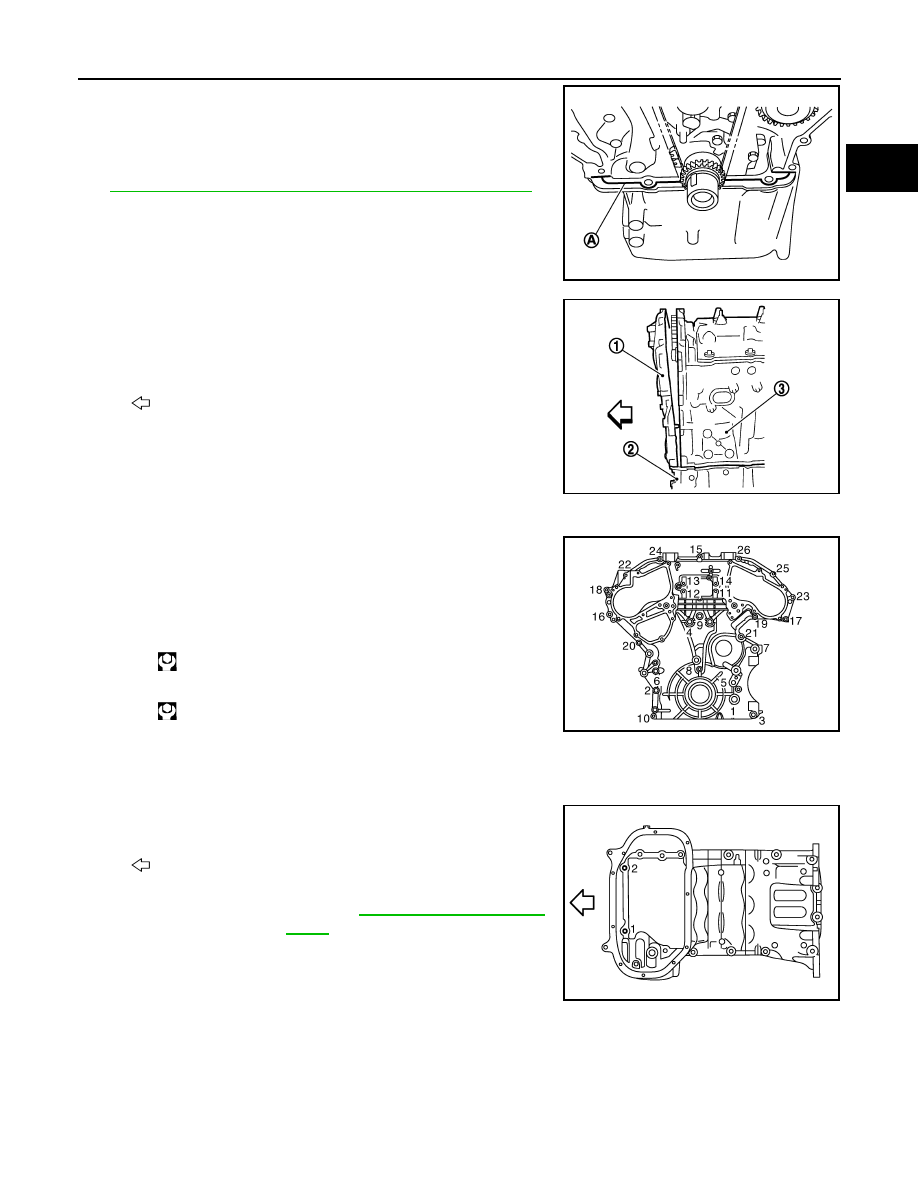

Apply liquid gasket to top surface of oil pan (upper) as shown in

the figure.

Use Genuine RTV silicone Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

c.

Assemble front timing chain case.

CAUTION:

• Be careful not to damage front oil seal by interference

with front end of crankshaft.

• Attaching should be done within 5 minutes after liquid

gasket application.

d.

Install front timing chain case as to fit its dowel pin hole together dowel pin on rear timing chain case.

e.

Tighten mounting bolts to the specified torque in numerical order

as shown in the figure.

• There are two types of mounting bolts. Refer to the following

for locating bolts.

f.

After all bolts are tightened, retighten them to the specified

torque in numerical order shown in the figure.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking on surface mating with oil pan (upper).

g.

Install two mounting bolts in front of oil pan (upper) in numerical

order shown in the figure.

11. Install valve timing control covers (bank 1 and bank 2) as follows:

A

:

φ

4.0 - 5.0 mm (0.157 - 0.197 in)

JPBIA0056ZZ

1

: Front timing chain case

2

: Oil pan (upper)

3

: Cylinder block

: Engine front

M10 bolts

: 1, 2, 3, 4, 5, 6, 7

: 55.0 N·m (5.6 kg-m, 41 ft-lb)

M6 bolts

: Except the above

: 12.7 N·m (1.3 kg-m, 9 ft-lb)

: Engine front

Tightening torque

: Refer to

JPBIA0058ZZ

JPBIA0046ZZ

JPBIA0047ZZ