Infiniti EX35. Manual - part 653

EC-354

< COMPONENT DIAGNOSIS >

[VQ35HR]

P1217 ENGINE OVER TEMPERATURE

>> Repair or replace malfunctioning part.

4.

CHECK RADIATOR CAP

Check radiator cap. Refer to

CO-11, "RADIATOR CAP : Inspection"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace radiator cap.

5.

CHECK THERMOSTAT

Check thermostat. Refer to

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace thermostat

6.

CHECK ENGINE COOLANT TEMPERATURE SENSOR

EC-174, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace engine coolant temperature sensor.

7.

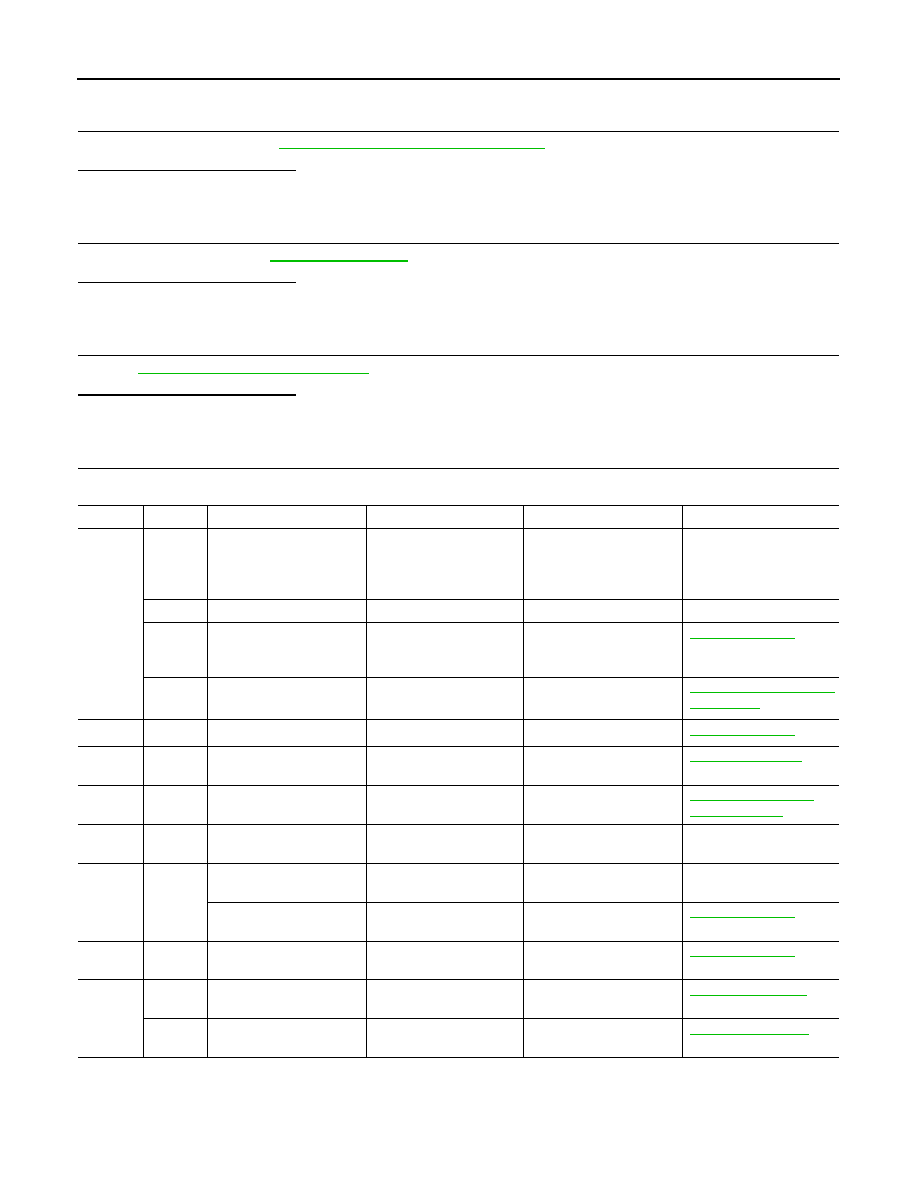

CHECK MAIN 12 CAUSES

If the cause cannot be isolated, check the following.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (56 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

Engine

Step

Inspection item

Equipment

Standard

Reference page

OFF

1

• Blocked radiator

• Blocked condenser

• Blocked radiator grille

• Blocked bumper

• Visual

No blocking

—

2

• Coolant mixture

• Coolant tester

50 - 50% coolant mixture

—

3

• Coolant level

• Visual

Coolant up to MAX level in

reservoir tank and radiator

filler neck

4

• Radiator cap

• Pressure tester

107 kPa

(1.1 kg/cm

2

, 16 psi) (Limit)

CO-11, "RADIATOR CAP

: Inspection"

ON*

2

5

• Coolant leaks

• Visual

No leaks

ON*

2

6

• Thermostat

• Touch the upper and

lower radiator hoses

Both hoses should be hot

ON*

1

7

• Cooling fan

• CONSULT-III

Operating

EC-443, "Component

Function Check"

OFF

8

• Combustion gas leak

• Color checker chemical

tester 4 Gas analyzer

Negative

—

ON*

3

9

• Coolant temperature

gauge

• Visual

Gauge less than 3/4 when

driving

—

• Coolant overflow to res-

ervoir tank

• Visual

No overflow during driving

and idling

OFF*

4

10

• Coolant return from res-

ervoir tank to radiator

• Visual

Should be initial level in

reservoir tank

OFF

11

• Cylinder head

• Straight gauge feeler

gauge

0.1 mm (0.004 in) Maxi-

mum distortion (warping)

12

• Cylinder block and pis-

tons

• Visual

No scuffing on cylinder

walls or piston