Infiniti EX35. Manual - part 636

EC-286

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0447 EVAP CANISTER VENT CONTROL VALVE

P0447 EVAP CANISTER VENT CONTROL VALVE

Description

INFOID:0000000003133436

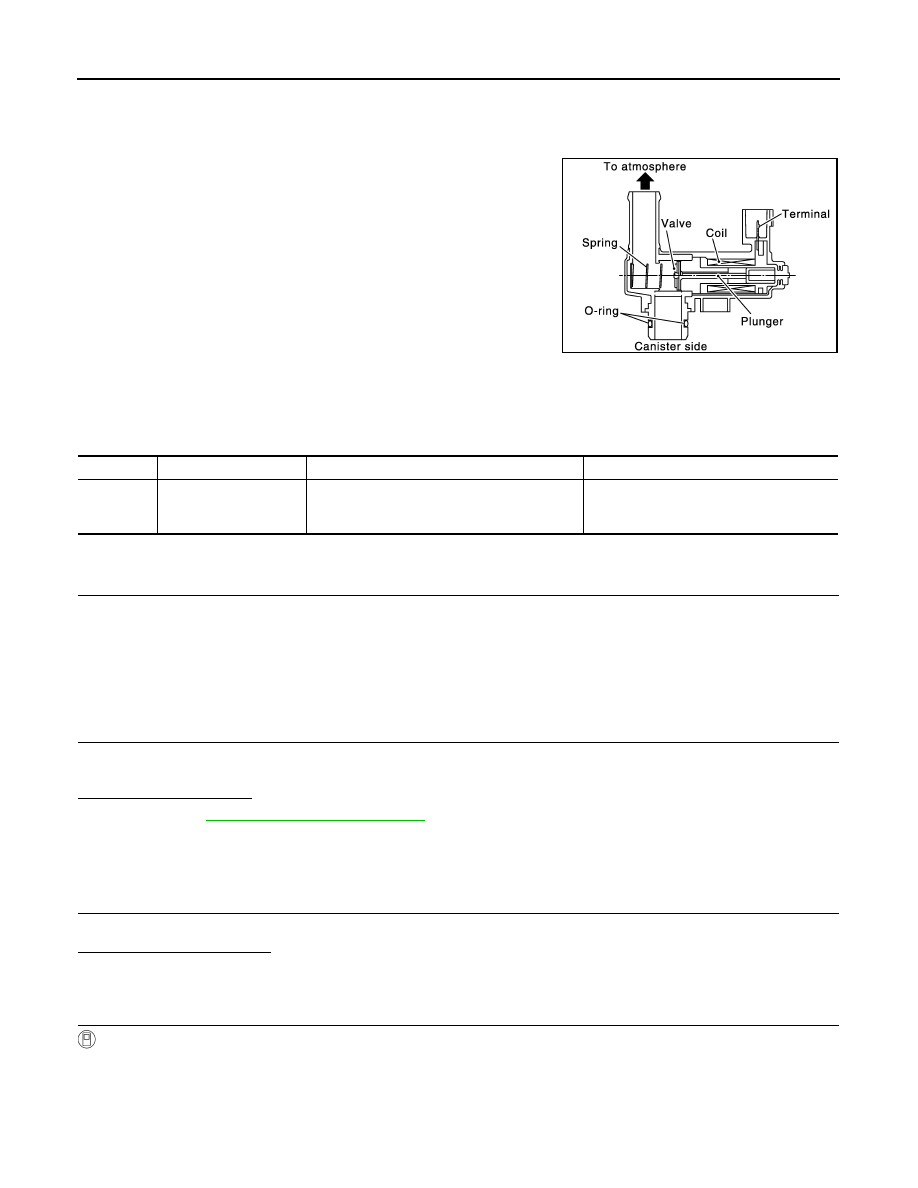

The EVAP canister vent control valve is located on the EVAP canis-

ter and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows “EVAP

Control System” diagnosis.

DTC Logic

INFOID:0000000003133437

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm battery voltage is more than 11 V at idle.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and wait at least 8 seconds.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000003133438

1.

INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK EVAP CANISTER VENT CONTROL VALVE CIRCUIT

With CONSULT-III

1.

Turn ignition switch OFF and then turn ON.

2.

Select “VENT CONTROL/V” in “ACTIVE TEST” mode with CONSULT-III.

3.

Touch “ON/OFF” on CONSULT-III screen.

4.

Check for operating sound of the valve.

PBIB1263E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0447

EVAP canister vent con-

trol valve circuit open

An improper voltage signal is sent to ECM

through EVAP canister vent control valve.

• Harness or connectors

(The valve circuit is open or shorted.)

• EVAP canister vent control valve