Infiniti EX35. Manual - part 625

EC-242

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0222, P0223, P2132, P2133 TP SENSOR

1.

Replace malfunctioning electric throttle control actuator.

2.

Go to

EC-242, "Special Repair Requirement"

.

>> INSPECTION END

7.

CHECK INTERMITTENT INCIDENT

GI-38, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000003133403

1.

CHECK THROTTLE POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Reconnect all harness connectors disconnected.

3.

EC-17, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

4.

Turn ignition switch ON.

5.

Set selector lever to D position.

6.

Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace malfunctioning electric throttle control actuator.

2.

Go to

EC-242, "Special Repair Requirement"

.

>> INSPECTION END

Special Repair Requirement

INFOID:0000000003133404

1.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-17, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 2.

2.

PERFORM IDLE AIR VOLUME LEARNING

EC-18, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> END

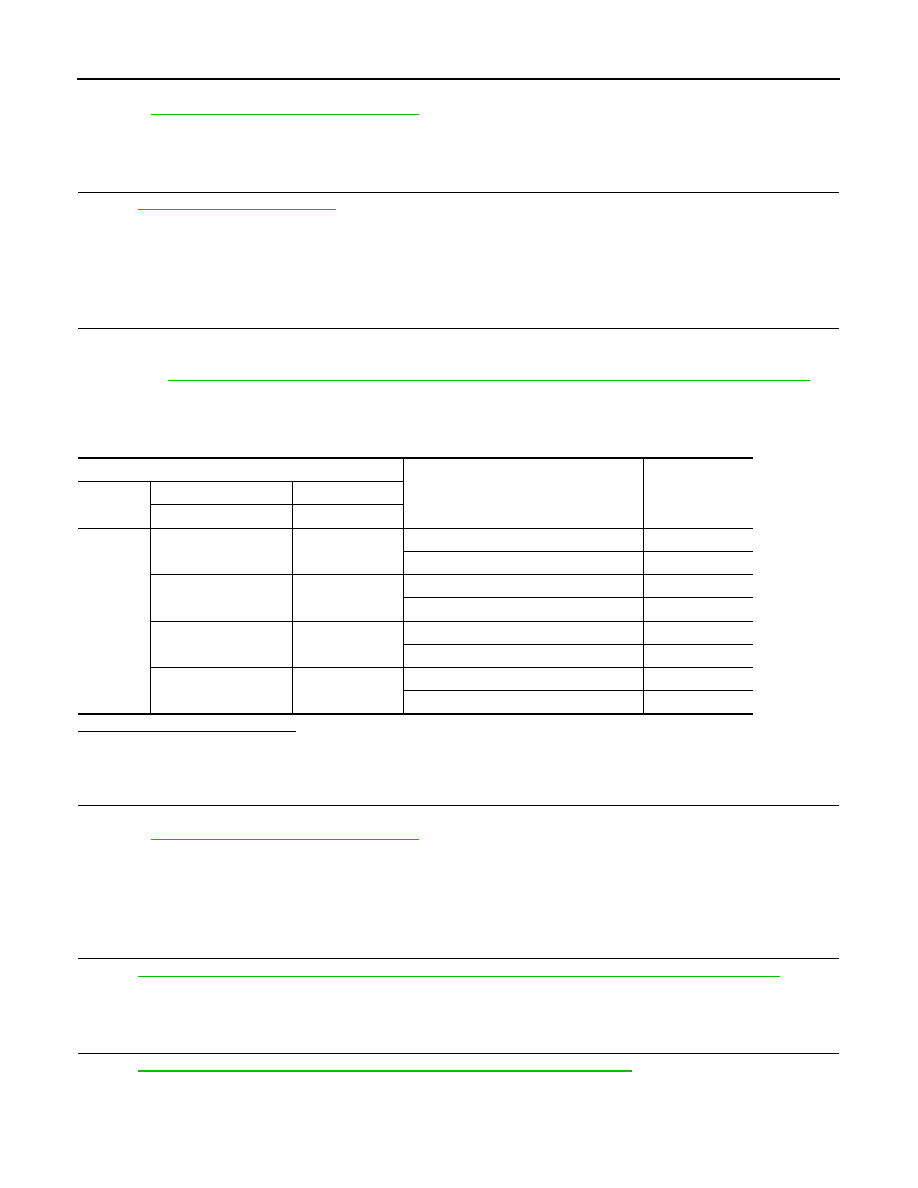

ECM

Condition

Voltage (V)

Connector

+

–

Terminal

Terminal

F101

30

[TP sensor 1 (bank 1)]

40

Accelerator pedal : Fully released

More than 0.36

Accelerator pedal : Fully depressed

Less than 4.75

31

[TP sensor 1 (bank 2)]

48

Accelerator pedal : Fully released

More than 0.36

Accelerator pedal : Fully depressed

Less than 4.75

34

[TP sensor 2 (bank 1)]

40

Accelerator pedal : Fully released

Less than 4.75

Accelerator pedal : Fully depressed

More than 0.36

35

[TP sensor 2 (bank 2)]

48

Accelerator pedal : Fully released

Less than 4.75

Accelerator pedal : Fully depressed

More than 0.36