Infiniti EX35. Manual - part 557

DLN-178

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200]

DIFFERENTIAL ASSEMBLY

8.

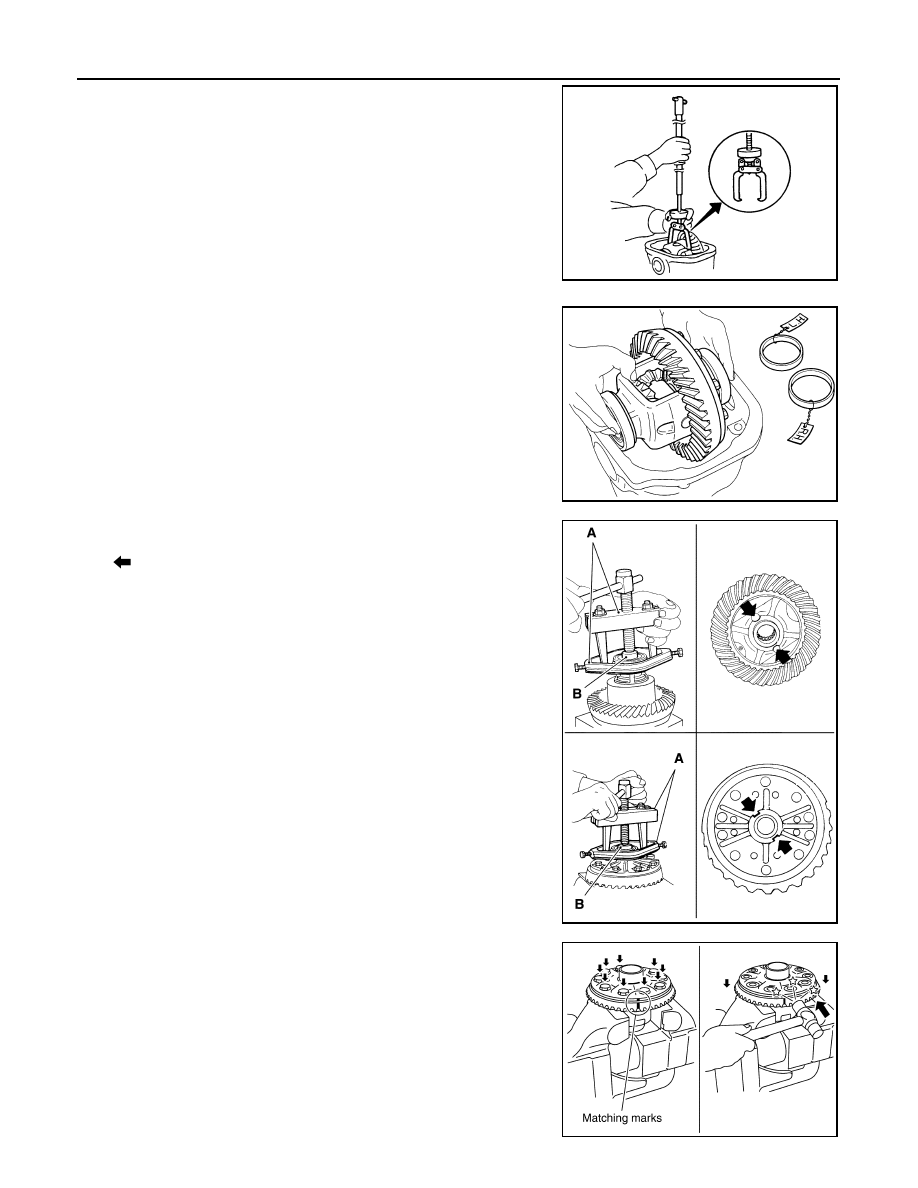

Lift differential case assembly out with a suitable tool.

• Keep side bearing outer races together with inner race. Never

mix them up.

Also, keep side bearing adjusting washers together with bear-

ings.

9.

Remove side bearing inner race.

To prevent damage to bearing, engage puller jaws in groove

(

).

CAUTION:

• To prevent damage to the side bearing and drive gear,

place copper plates between these parts and vise.

• It is not necessary to remove side bearing inner race

except when it is replaced.

10. For proper reinstallation, paint matching marks on one differen-

tial case assembly.

CAUTION:

For matching marks, use paint. Never damage differential

case and drive gear.

11. Remove drive gear mounting bolts.

12. Tap drive gear off differential case assembly with a soft hammer.

CAUTION:

Tap evenly all around to keep drive gear from bending.

PDIA0547E

SPD527

A

: Puller [SST: ST33051001 (J-22888-20)]

B

: Base [SST: ST33061000 (J-8107-2)]

PDIA0758J

PDIA0496E