Infiniti EX35. Manual - part 471

DLK-98

< COMPONENT DIAGNOSIS >

[INTELLIGENT KEY SYSTEM]

KEY SLOT ILLUMINATION

KEY SLOT ILLUMINATION

Description

INFOID:0000000003728930

Blinks when Intelligent Key insertion is required.

Component Function Check

INFOID:0000000003728931

1.

CHECK FUNCTION

Check key slot illumination (“KEY SLOT ILLUMI”) Active Test mode.

Is the inspection result normal?

YES

>> Key slot function is OK.

NO

>> Refer to

.

Diagnosis Procedure

INFOID:0000000003728932

1.

CHECK FUSE

1.

Turn ignition switch OFF.

2.

Check 10 A fuse, [No.9, located in fuse block (J/B)].

Is fuse fusing?

YES

>> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

NO

>> GO TO 2.

2.

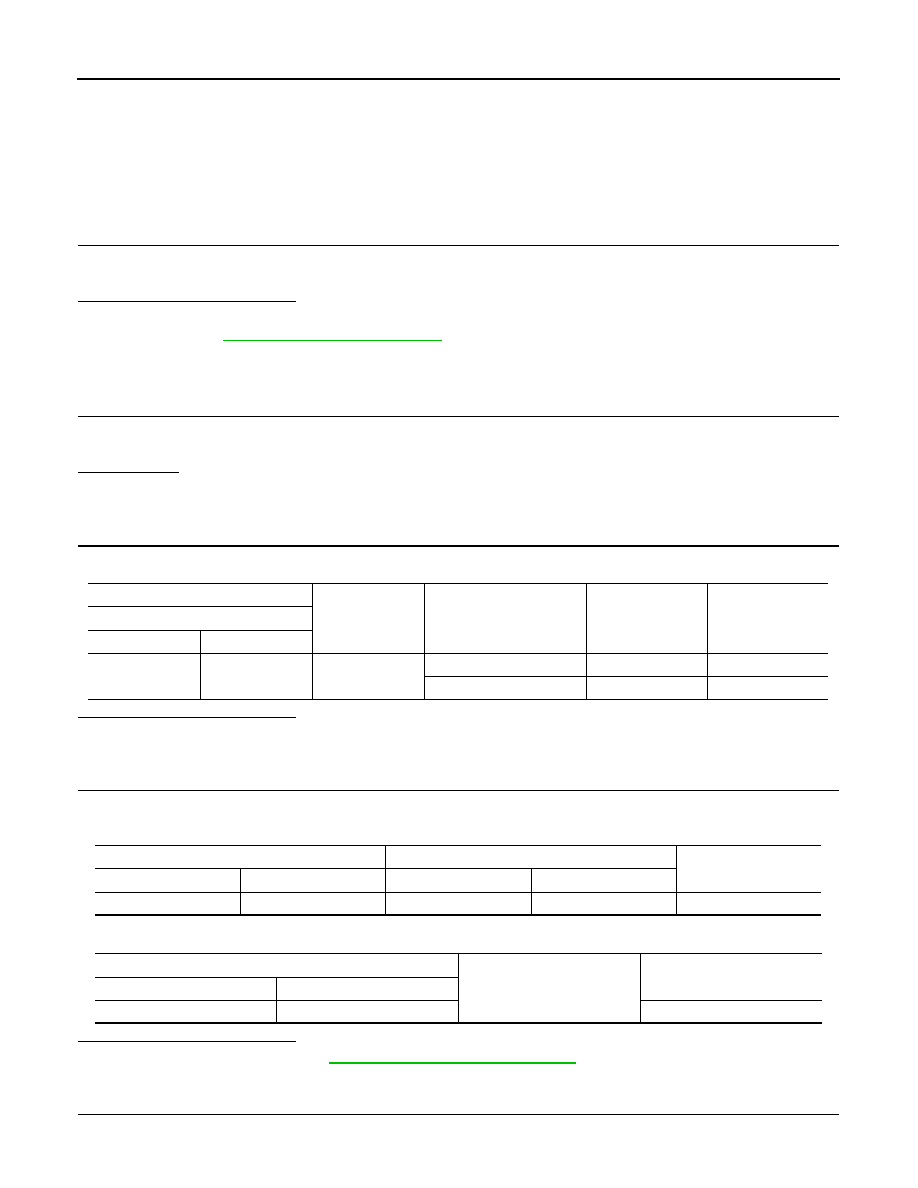

CHECK KEY SLOT ILLUMINATION OUTPUT SIGNAL

Check voltage between key slot harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 4.

3.

CHECK KEY SLOT CIRCUIT

1.

Disconnect BCM and key slot connector.

2.

Check continuity between BCM harness connector and key slot harness connector.

3.

Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES

>> Replace BCM. Refer to

BCS-84, "Removal and Installation"

NO

>> Repair or replace harness.

4.

CHECK KEY SLOT POWER SUPPLY CIRCUIT

1.

Disconnect key slot connector.

(+)

(–)

Condition

Key slot

illumination

Voltage (V)

(Approx.)

Key slot

Connector

Terminal

M22

6

Ground

Intelligent Key inserted

OFF

Battery voltage

Intelligent Key removed

ON

0

BCM

Key slot

Continuity

Connector

Terminal

Connector

Terminal

M122

92

M22

6

Existed

BCM

Ground

Continuity

Connector

Terminal

M122

92

Not existed