Content .. 1437 1438 1439 1440 ..

Infiniti EX35. Manual - part 1439

TM-144

< ON-VEHICLE MAINTENANCE >

[5AT: RE5R05A]

A/T FLUID COOLER

DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exterior may lead to inaccurate debris identification.

1.

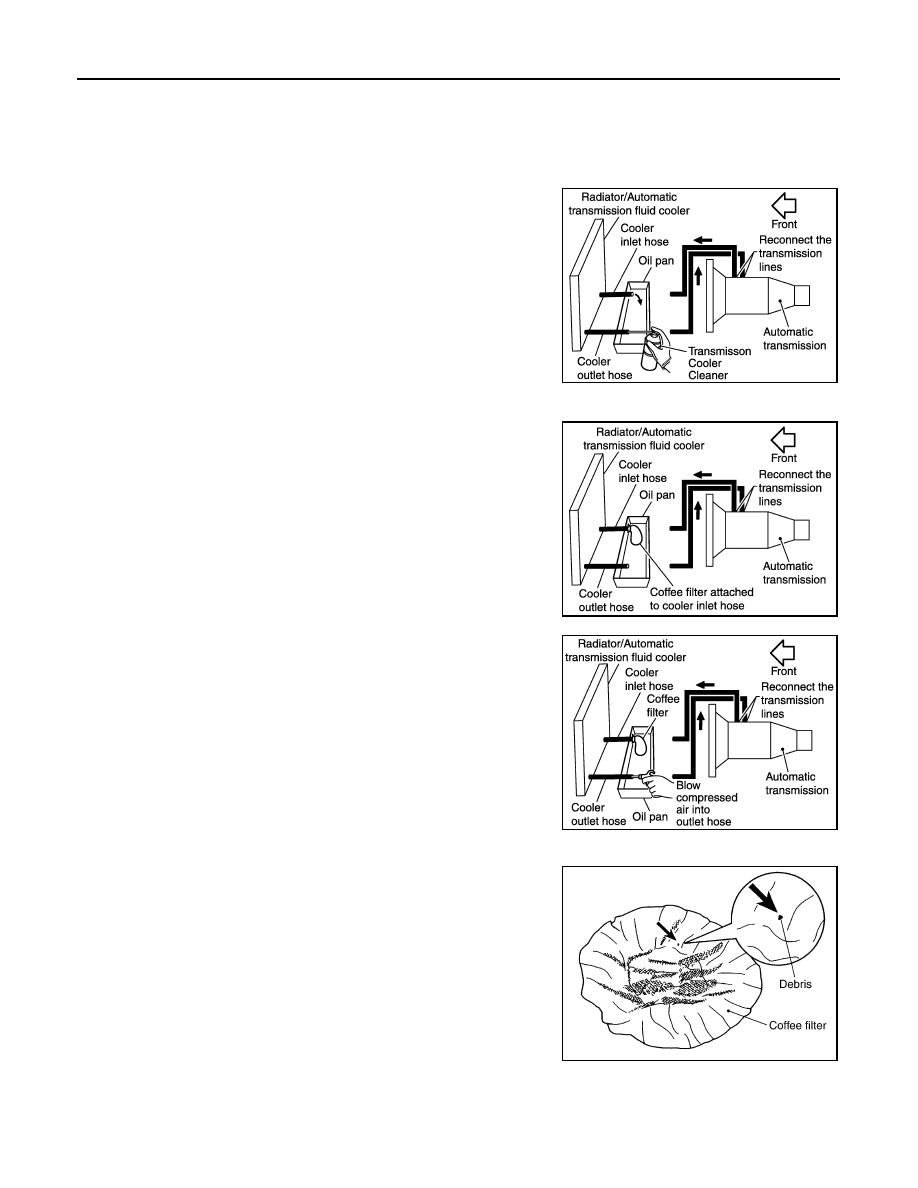

Position an oil pan under the A/T inlet and outlet cooler hoses.

2.

Clean the exterior and tip of the cooler inlet hose.

3.

Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

4.

Hold the hose and can as high as possible and spray Transmis-

sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until ATF flows out of the cooler inlet hose for 5 seconds.

5.

Tie a common white, basket-type coffee filter to the end of the

cooler inlet hose.

6.

Insert the tip of an air gun into the end of the cooler outlet hose.

7.

Wrap a shop rag around the air gun tip and end of cooler outlet

hose.

8.

Blow compressed air regulated to 5 to 9 kg/cm

2

(71 to 128 psi)

through the cooler outlet hose to force any remaining ATF into

the coffee filter.

9.

Remove the coffee filter from the end of the cooler inlet hose.

10. Perform “INSPECTION PROCEDURE”.

INSPECTION PROCEDURE

1.

Inspect the coffee filter for debris.

a.

If small metal debris less than 1 mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T fluid cooler/radiator can be re-used and

the procedure is ended.

JPDIA0712GB

JPDIA0714GB

JPDIA0715GB

SCIA2967E