Hummer H1 (2006+). Manual - part 351

12-80

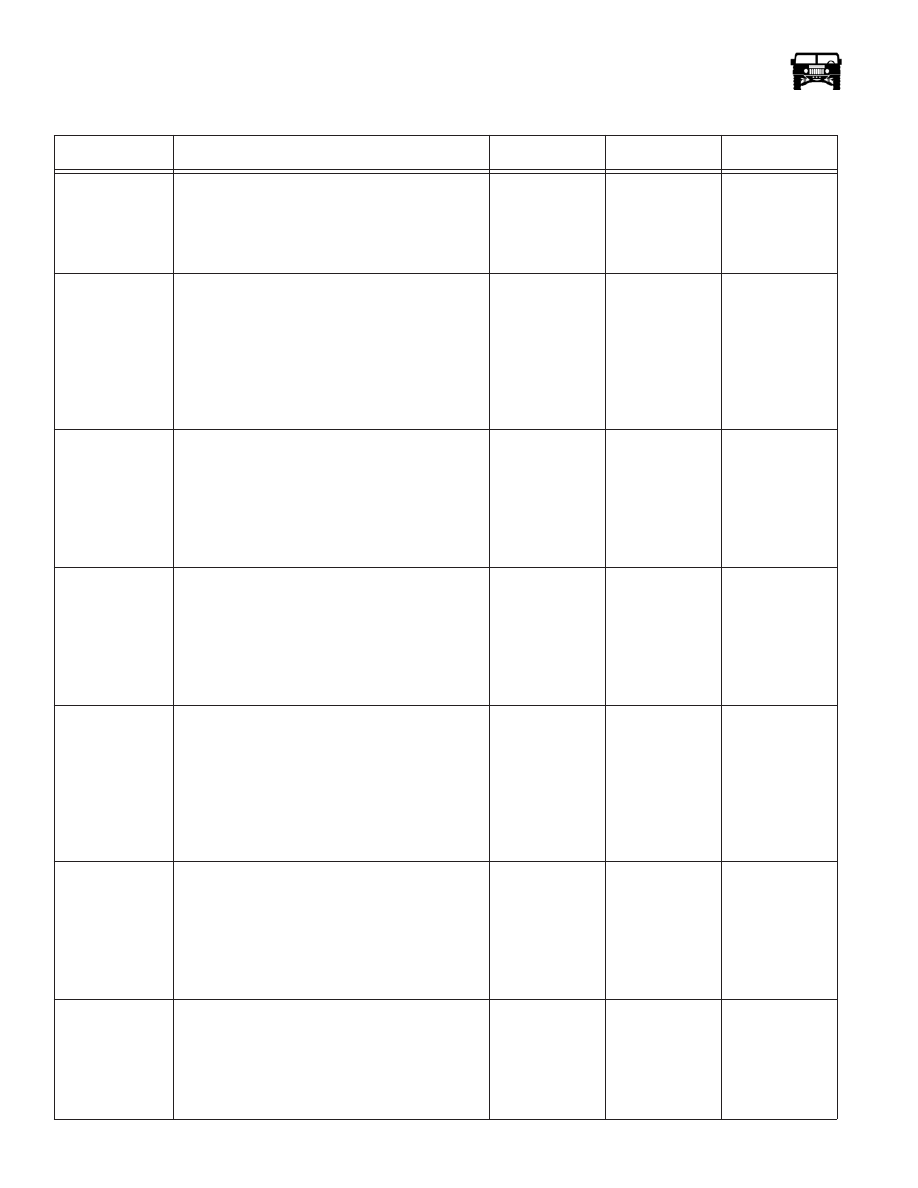

Electrical System

_______________________________________________________

2

Remove the wiper switch from the instrument

panel. Disconnect the wiper switch from the har-

ness.Using a DVOM, measure resistance between

terminals 2 and 3 of the switch. Is the resistance

below the specified value?

<.2

1

Connect the

intermittent

wiper switch to

the harness.

Go to step 3.

Replace the

wiper switch.

3

Turn the ignition switch to the “RUN” position

and the intermittent wiper switch to “MEDIUM

DELAY”. Using a DVOM, set to measure volt-

age, back probe the brown wire (CKT 945) at the

intermittent switch. Voltage should pulse from 12

volts to 0 volts every 2-7 seconds depending on

the switch position. Is the voltage in the specified

range.

+12v pulse

2-7 seconds

Go to step 5.

Go to step 4.

4

Ignition should be in the “RUN” position. Using a

DVOM, set to measure the voltage, back probe

the yellow wire (CKT 65) at the intermittent

wiper switch. Is the specified voltage present?

+12v

Replace the

intermittent

wiper switch.

Repair the open

or bad connec-

tion in CKT 65

between the

intermittent

wiper switch

and fuse 13G.

5

Remove the intermittent wiper relay from the fuse

box. Turn the ignition switch to the “RUN” posi-

tion. Using a DVOM, measure voltage drop

between the brown wire (CKT 945) and the black

wire (CKT 59). The voltage should pulse from 12

volts to 0 volts every 2 to 7 seconds. Is the volt-

age in the specified ranges?

+12v pulse

2-7 seconds

Go to step 7.

Go to step 6.

6

Using a DVOM, set to measure resistance, mea-

sure resistance to ground at the black wire (CKT

59) of the fuse box. Is resistance below specifica-

tion?

<.2

1

Repair the open

or bad connec-

tion, in CKT

945 between the

intermittent

wiper switch

and the intermit-

tent wiper relay.

Repair open or

bad connection

in CKT 59

between the

intermittent

wiper relay and

G4.

7

Turn the ignition to the “RUN” position. Use a

DVOM, to measure voltage drop between the yel-

low wire (CKT 65) and the black wire (CKT 59).

Is the specified voltage present?

+12v

Go to step 8.

Repair the open

or bad connec-

tion in CKT 65

between fuse

13G and the

intermittent

wiper relay.

8

With the ignition switch in the “RUN” position

and the wipers on “LOW”, check the voltage drop

between the dark blue wire (CKT 28) at the motor

and the black wire (CKT 59) at the relay. Does the

voltage switch from 12 volts to 0 volts as the

wiper completes its cycle?

0v – +12v – 0v

Replace the

intermittent

wiper relay.

Go to step 9.

Windshield Wipers Intermittent Speeds Inoperative (Cont’d) (Figure 12-158)

Step

Action

Value(s)

Yes

No