Hummer H1 (2006+). Manual - part 348

12-68

Electrical System

_______________________________________________________

readings should approximate the specifications. The coolant temperature warning light and gauge reference the same dark green

wire (CKT 39). If the light is activating at a questionable point, reference the chart to verify accuracy (Figure 12-110).

Fuel Gauge and Warning Light Calibration.

To check accuracy of the fuel gauge or warning light use the calibration chart. The gauge panel must be connected to the harness to verify

the fuel level. Back probe the signal wire with a DVOM, and check the resistance verses the gauge readings. The readings should approx-

imate the specifications. The fuel level warning light and gauge reference the same pink wire (CKT 29). If the light is activating at a ques-

tionable point, reference the chart to verify accuracy.

Warning Lights for the Coolant/Fuel Module

All the LEDs on the coolant/fuel module receive voltage from a control circuit that is built in to the module. This controller is powered up

with system voltage on the tan wire (CKT 916) (Figure 12-112).

The warning and indicator lights are also connected to a 4.1 second timed bulb check circuit. This is activated by a voltage signal being

supplied to the module through the grey wire with a black tracer (CKT 911). When the module receives the voltage signal it activates an

internal timer which supplies a ground to all the LEDs on the board.

ABS Warning Light

The ABS warning Light is an amber LED. It is controlled by a ground signal supplied by the ABS ECU on the red wire (CKT 603).

Brake Warning Light

The brake warning light is a red LED. It is controlled by a ground signal supplied by either the parking brake switch or the low brake fluid

switch. The signal is supplied on the brown wire (CKT 42).

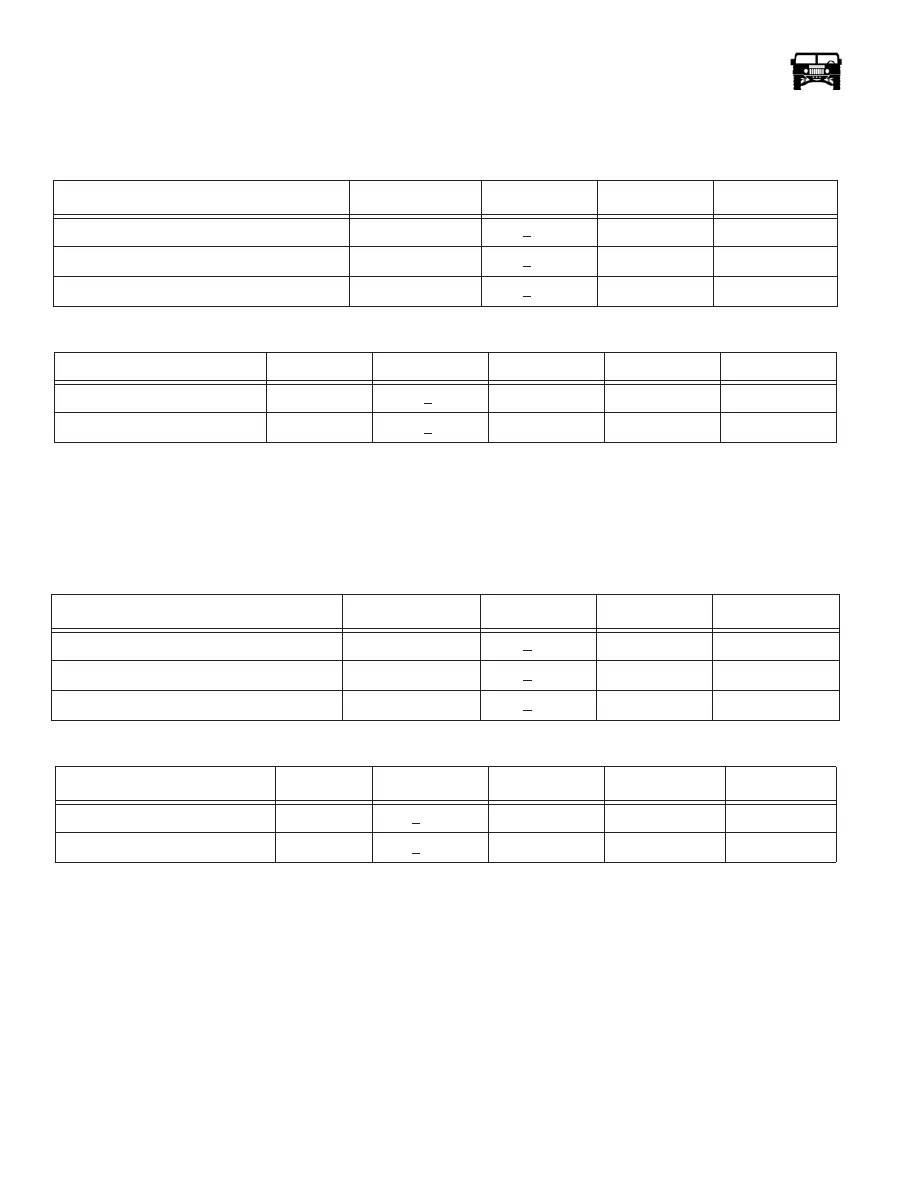

Coolant Temperature Gauge Calibration Check

Approximate Reading

Input

Input Tol.

Ascending

Descending

Cold

1500

1

+ 5

1

X

Mid. Point

260

1

+ 5

1

X

Hot

56

1

+ 3

1

X

Coolant Temperature Light Calibration Check

Approximate Reading

Inputs

Input Tol.

Ascending

Descending

Status

Red Band

75

1

+5

X

On

Gray Band

>80

1

+5

X

Off

Fuel Gauge Calibration Checks

Approximate Readings

Inputs

Input Tol

Ascending

Descending

Empty

272

1

+5

1

X

1/2

113

1

+5

1

X

Full

20

1

+3

1

X

Low Fuel Warning Light

Approximate Readings

Inputs

Input Tol

Ascending

Descending

Status

1/8

210

1

+10

1

X

ON

1/4

145

1

+10

1

X

OFF