Hummer H1 (2006+). Manual - part 341

12-40

Electrical System

_______________________________________________________

12.

Turn the ignition ON leaving the engine OFF.

Reconnect the glow plug relay control harness.

With a DMM connected to ground, back probe

the glow plug relay signal circuit (506 LB) at the

ECM harness connector. Use a scan tool to com-

mand the glow plugs ON. Observe the DMM

while the glow plugs are commanded ON.

Is the voltage at the specified value?

5.0-5.6 Volts

Go to step 21.

Go to step 13.

13.

Turn the ignition OFF. Disconnect the right and

left bank glow plug output circuit connectors at

the glow plug relay. With an unpowered test lamp

connected to B+, probe each circuit.

Does each circuit turn ON the test lamp?

Go to step 26.

Go to step 14.

14.

Turn the ignition OFF. Disconnect each glow plug

connector at the glow plug that did not illuminate

the test lamp. With an unpowered test lamp con-

nected to B+, probe the terminal on the glow

plug.

Does each glow plug illuminate the test lamp?

Go to step 26.

Go to step 25.

15.

Turn the ignition OFF. Disconnect each glow plug

connector at the glow plug. With an unpowered

test lamp connected to B+, probe each circuit at

the glow plug output connectors.

Is the test lamp OFF at each of the circuits?

Go to step 20.

Go to step 27.

16.

Repair an open or a short to ground in the glow

plug relay ignition feed circuit (CKT 239 RD).

Did you complete the repair?

Go to step 30.

17.

Repair any opens or poor connections in the glow

plug relay ground circuit (BK).

Did you complete the repair?

Go to step 30.

18.

Inspect the glow plug relay control circuit (466

YL) for an open or short to ground. If the glow

plug relay control circuit is open or shorted to

ground, repair as necessary.

Did you find and correct the condition?

Go to step 30.

Go to step 19.

19.

Inspect the glow plug relay control circuit (CKT

466 YL) for a proper connection at the ECM and

replace the terminal if necessary.

Did you find an improper connection and make

the necessary repair?

Go to step 30.

Go to step 29.

20.

Inspect the glow plug relay signal circuit (CKT

506 LB) for an open or short to ground. If the

glow plug relay signal circuit is open or shorted

to ground, repair as necessary.

Did you find and correct the condition?

Go to step 30.

Go to step 28.

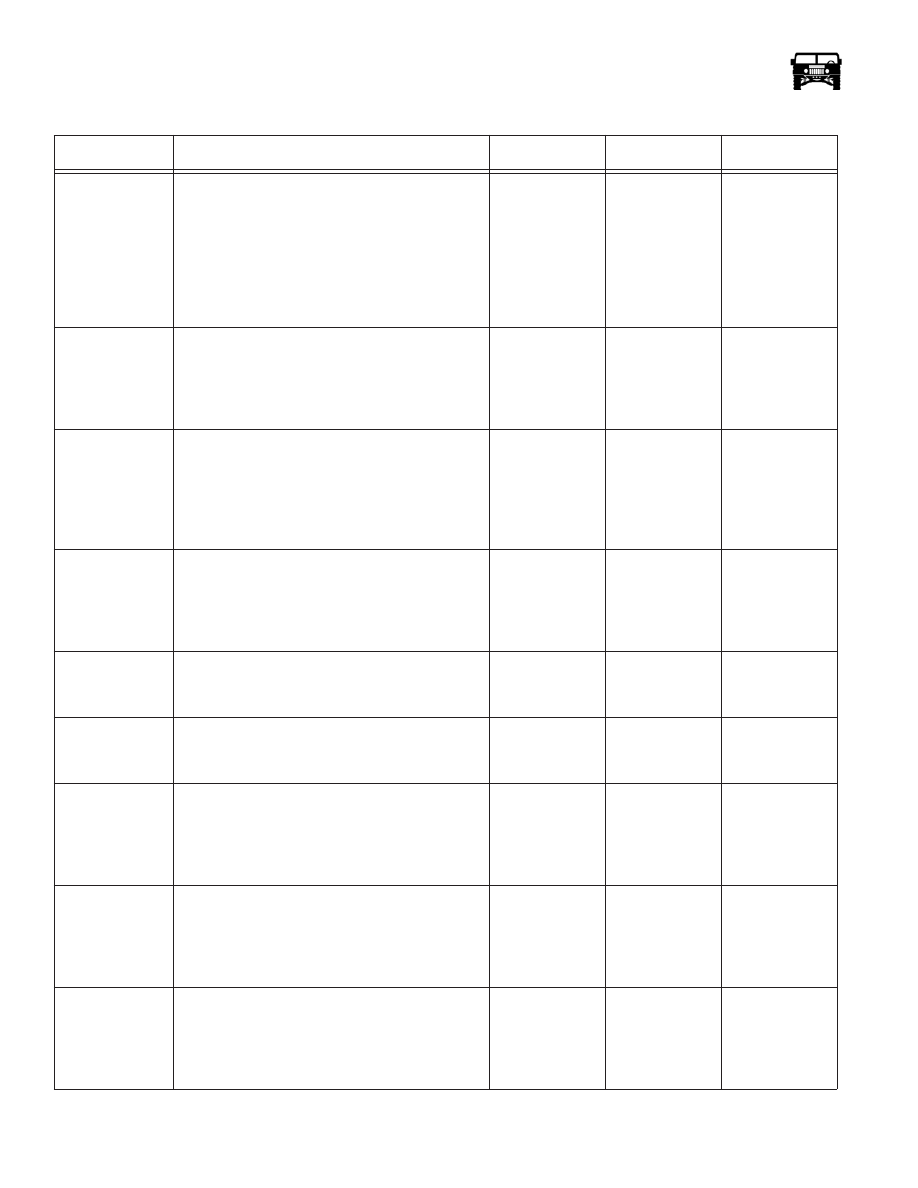

Glow Plugs Inoperative (Cont’d) (Figure 12-117)

Step

Action

Value

Yes

No