Hummer H1 (2006+). Manual - part 320

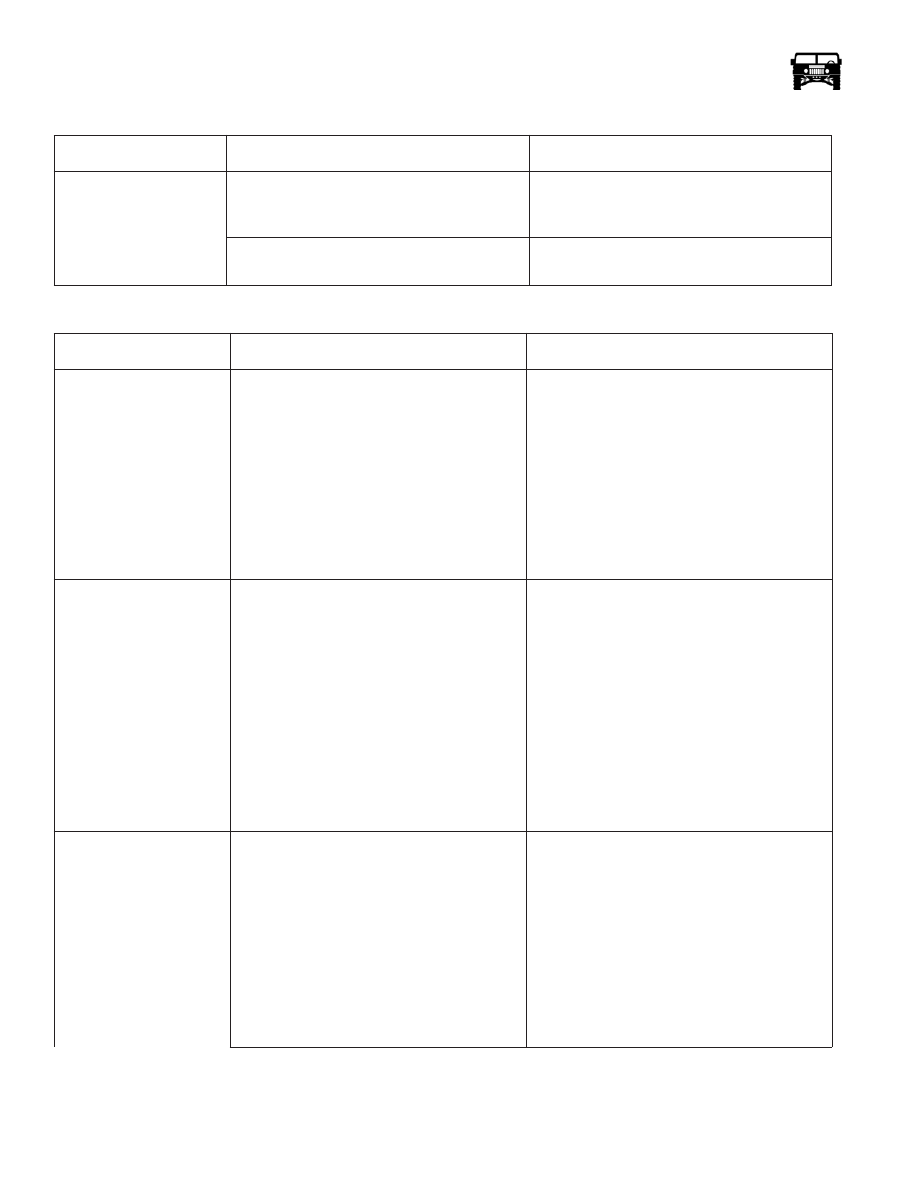

11-14 Heating/Ventilation/Air Conditioning (HVAC)

______________________

Low Side and High Side

Normal But Cooling is

Inadequate

1.

Air and/or moisture in the system.

1.

Leak test the system. Repair leaks if neces-

sary. If leaks are not evident, evacuate and

recharge the system.

2.

Receiver/Dryer fault.

2.

Evacuate the system, replace the receiver/

dryer and recharge the system.

Compressor Diagnosis

Condition

Possible Cause

Correction

Compressor Noise

1.

System overcharge.

1.

Recover all R-134a with J–39500-A ser-

vice cart and recharge with the proper

charge.

2.

Drive belt problem.

2.

Replace the belt if worn, frayed, cut or

torn.

3.

Compressor clutch fault.

3.

Replace the core or pulley bearing as

needed.

4.

Compressor internal fault.

4.

Replace the compressor if pressure test

indicates worn, inoperative condition.

Compressor Does Not

Engage

1.

System fuse blown.

1.

Replace the fuse. Check the circuit for

shorts, ground.

2.

Clutch wires damaged.

2.

Repair the wires.

3.

Pressure cycling clutch or A/C cutout

switch fault.

3.

Replace the switch(s) as needed.

4.

Compressor clutch failure.

4.

Replace the clutch core and/or pulley as

needed.

5.

Compressor seized.

5.

Replace compressor.

6.

High engine coolant temperature trigger-

ing A/C cutout switch.

6.

Let the engine cool down and fix the

engine cooling system problem first.

Compressor Engages but

Cooling is Inadequate

1.

A/C duct restrictions, loose connections.

1.

Repair as needed.

2.

System leaks (high side pressure below

50 psi (345 kPa)).

2.

Check for leaks with J-41995 leak

detection tool and repair as needed.

3.

Expansion valve inoperative.

3.

Replace the valve.

4.

Receiver/Dryer fault.

4.

Replace the receiver/dryer

5.

Condenser fault.

5.

Replace the condenser.

6.

Compressor

internal

wear.

6.

Replace the compressor if pressure

indicates internal wear or damage.

A/C Pressure Test Diagnosis (Continued)

Condition

Possible Cause

Correction