Hummer H1 (2006+). Manual - part 240

7-42

Brake System

_____________________________________________________________

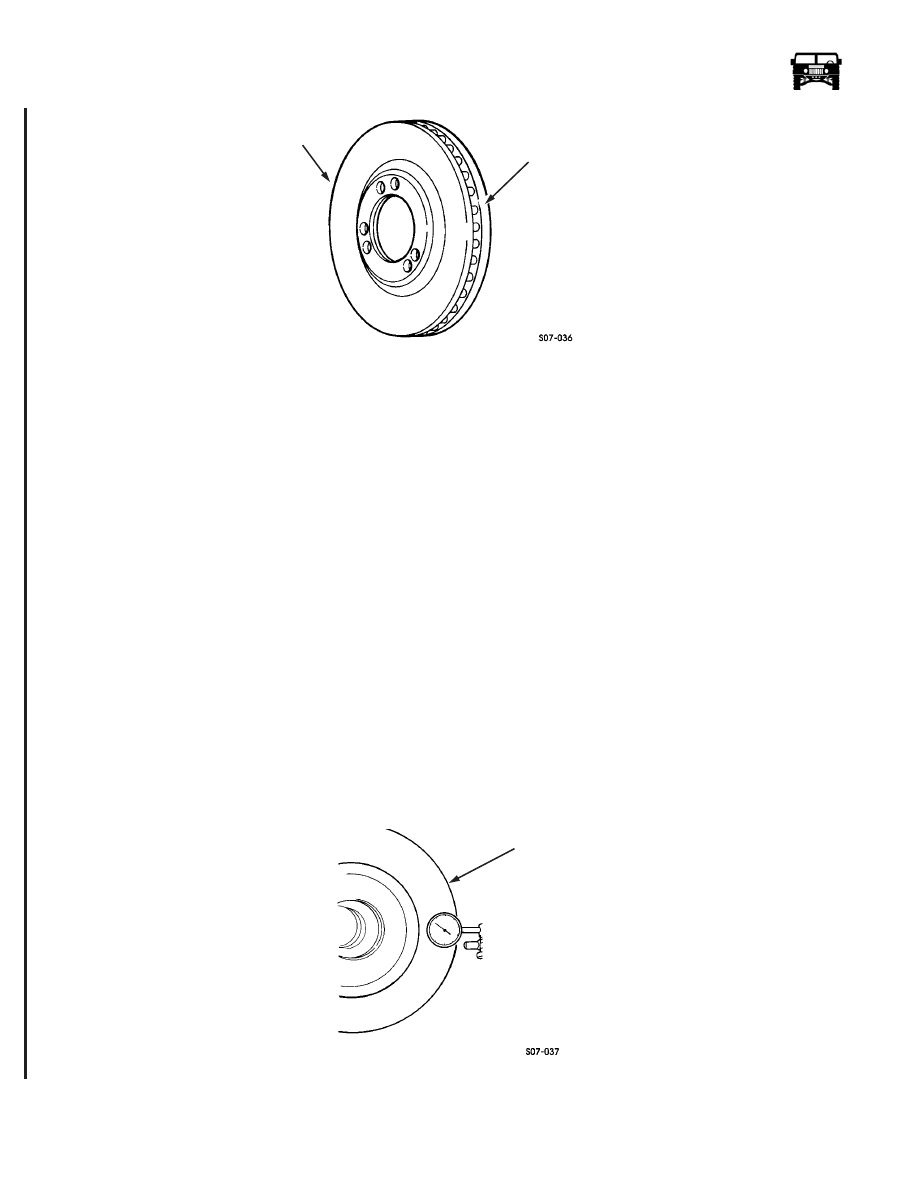

Figure 7-40: Brake Rotor and Cooling Fins

NOTE: Clean debris from the cooling fins if necessary.

REFINISHING BRAKE ROTORS

Refinish the rotors only under the following circumstances:

1.

There is a complaint of brake pulsation.

2.

There is excessive scoring.

Brake rotors have a minimum thickness dimension cast into them. Do not use a brake rotor that will not meet the dimensions

shown in the specifications. Original equipment rotors are surface finished to 0.25-1.27 micrometers (10-50 microinches).

Accurate control of rotor tolerances is necessary for the proper performance of disc brakes. Machining should be done only with

precision equipment. Service the machining equipment on a regular basis following the manufacturer’s recommended maintenance

procedures.

When you refinish rotors, make sure the attaching adapters, tool holders, vibration dampeners, and tool bits are in good condition.

Always use sharp cutting tools or bits and use only replacement cutting bits recommended by the equipment manufacturer. Dull or

worn tools leave a poor surface finish that will affect initial brake performance. Vibration dampening attachments should always

be used when refinishing braking surfaces. These attachments eliminate tool chatter to allow for a better surface finish. Make sure

these adaptors are clean and free of nicks. The optional swirl pattern finish will provide the best initial braking effectiveness. For

this, use a sanding disc power tool with 120 grit disc for about 10 seconds per side.

Checking Lateral Runout

1.

Mount the dial indicator with the stylus contacting the rotor surface 1 in. (25 mm) in from the outer edge (Figure 7-41).

2.

Turn the rotor 360° and note the total indicator reading (TIR).

If lateral runout exceeds 0.004 in. (0.10 mm) TIR, replace or refinish the rotor.

Figure 7-41: Checking Rotor for Lateral Runout

BRAKE ROTOR

COOLING FINS

ROTOR

6-1-05