Hummer H1 (2006+). Manual - part 214

6-6

Wheels and Tires/Central Tire Inflation System (CTIS)

_________________

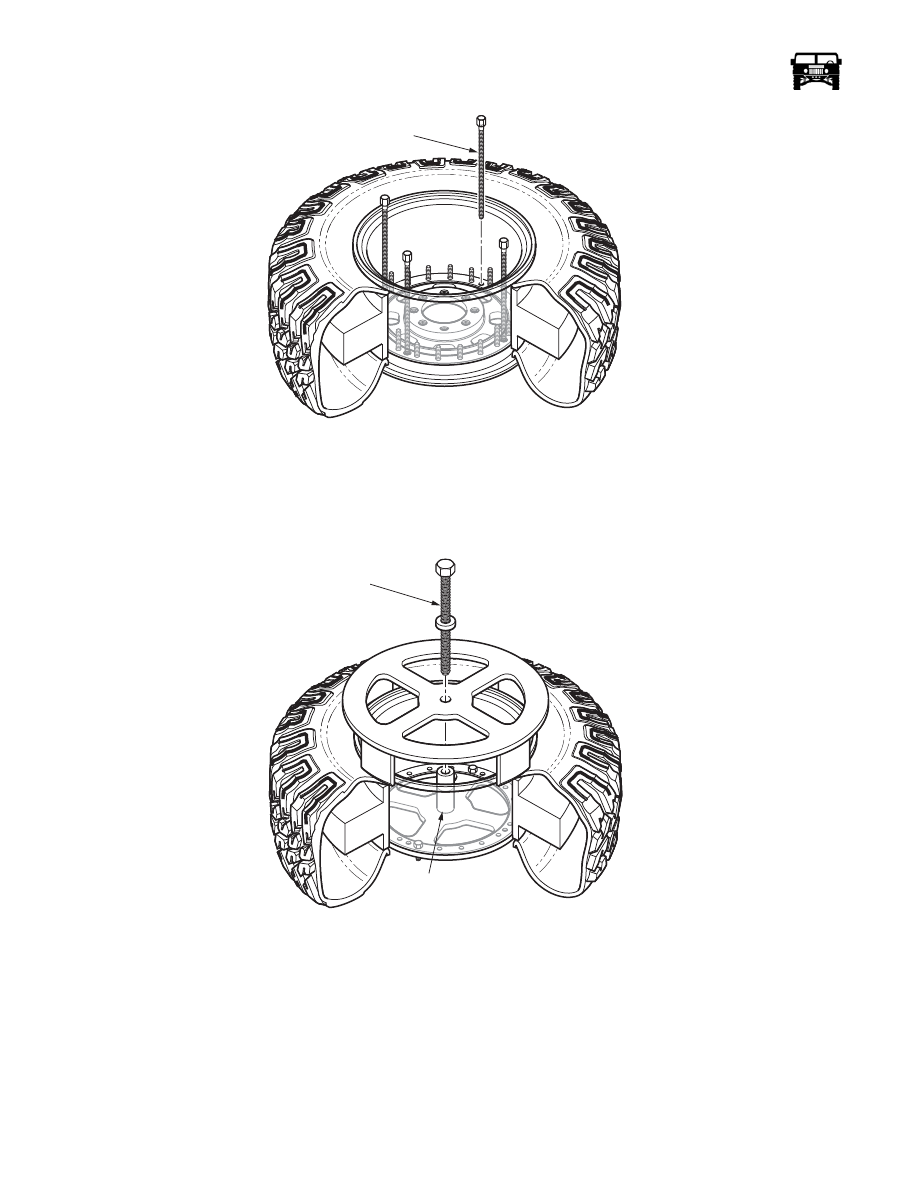

Figure 6-6: Wheel Separation Bolts

13. Remove the o-ring seal from the inner rim half. Discard the o-ring seal.

14. Assemble the inner bead separator tool (J–45770) by placing the half with the welded center shaft against the o-ring surface of

the inner wheel half and secure with the two bolts and washers provided (Figure 6-7). Place the other half of the tool on the

inner tire bead surface and install the large press bolt through to the threaded hole in the shaft.

Figure 6-7: Inner Half Bead Separator

15. Rotate the press bolt until the tire bead is released from the inner wheel half. Remove the tool and the inner wheel half from

the tire/runflat assembly.

WARNING: Balance weights contain lead. Wash hands after handling.

16. Remove the balance weights from the rim halves. Discard the balance weights.

17. Lay the tire flat.

WARNING: To avoid injury, ensure run flat compressor strap is centered around run flat.

03-S06-003

SEPARATOR

BOLT

03-S06-004

CENTER

SHAFT

PRESS

BOLT