Hummer H1 (2006+). Manual - part 85

OBD-184

On-Board Diagnostics

_____________________________________________

DTC P0507 Idle Speed Too High

Circuit Description

The engine control module (ECM) adjusts the fuel delivery in order to control crankshaft speed at idle. If the ECM detects the en-

gine speed is incorrect for the amount of fuel that is delivered, DTC P0507 sets.

Conditions for Setting the DTC

The actual idle speed is more than 100 RPM over the target idle speed.

Action Taken When the DTC Sets

• The control module illuminates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the diag-

nostic runs and fails.

• The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the

control module stores this information in the Failure Records. If the diagnostic reports a failure on the second consecu-

tive ignition cycle, the control module records the operating conditions at the time of the failure. The control module

writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The control module turns OFF the malfunction indicator lamp (MIL) after 3 consecutive ignition cycles that the diagnostic

runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission related

diagnostic.

• Clear the MIL and the DTC with a scan tool.

Diagnostic Aids

Inspect for one of the following:

• A crankcase overfill causing oil to be forced through the positive crankcase ventilation (PCV) system

• An aftermarket performance kit using an external fuel source

• An engine mechanical condition

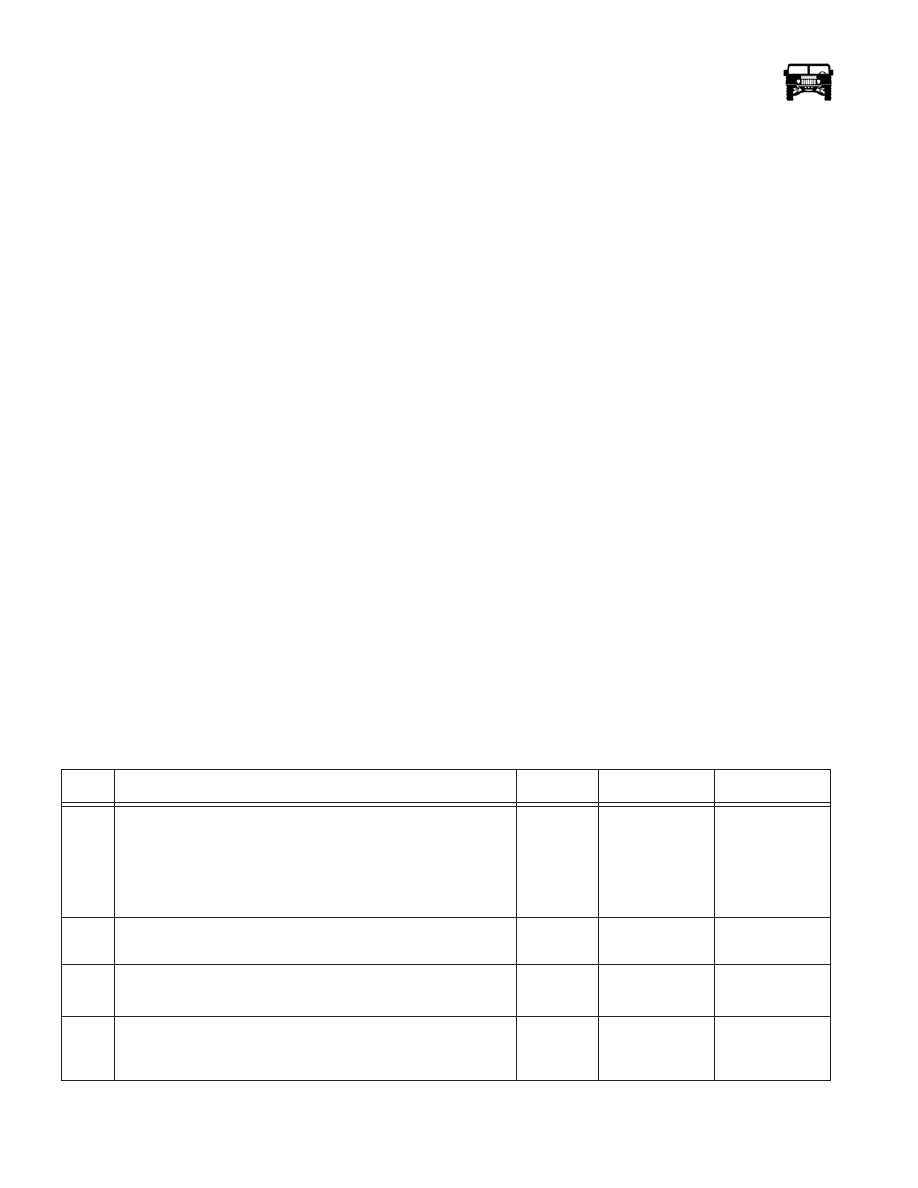

Step

Action

Value(s)

Yes

No

1

NOTE: Before clearing DTC(s) use the scan tool “Capture info”

to record Freeze Frame and Failure Records for reference, as data

will be lost when “Clear Info” function is used

Was the “On-Board Diagnostic (OBD) System Check” per-

formed?

Go to step 2.

Go to OBD Sys-

tem Check.

2

Are any other DTCs set?

Go to the DTC

in order

Go to Step 3

3

Attempt to start the engine.

Does the engine crank?

Go to Step 4

Go to Engine

Will Not Crank

4

Does the engine start?

Go to Diagnos-

tic Aids

Go to Engine

Cranks but Does

Not Run