Hummer H1 (2006+). Manual - part 33

2-38

Engine

______________________________________________________________________

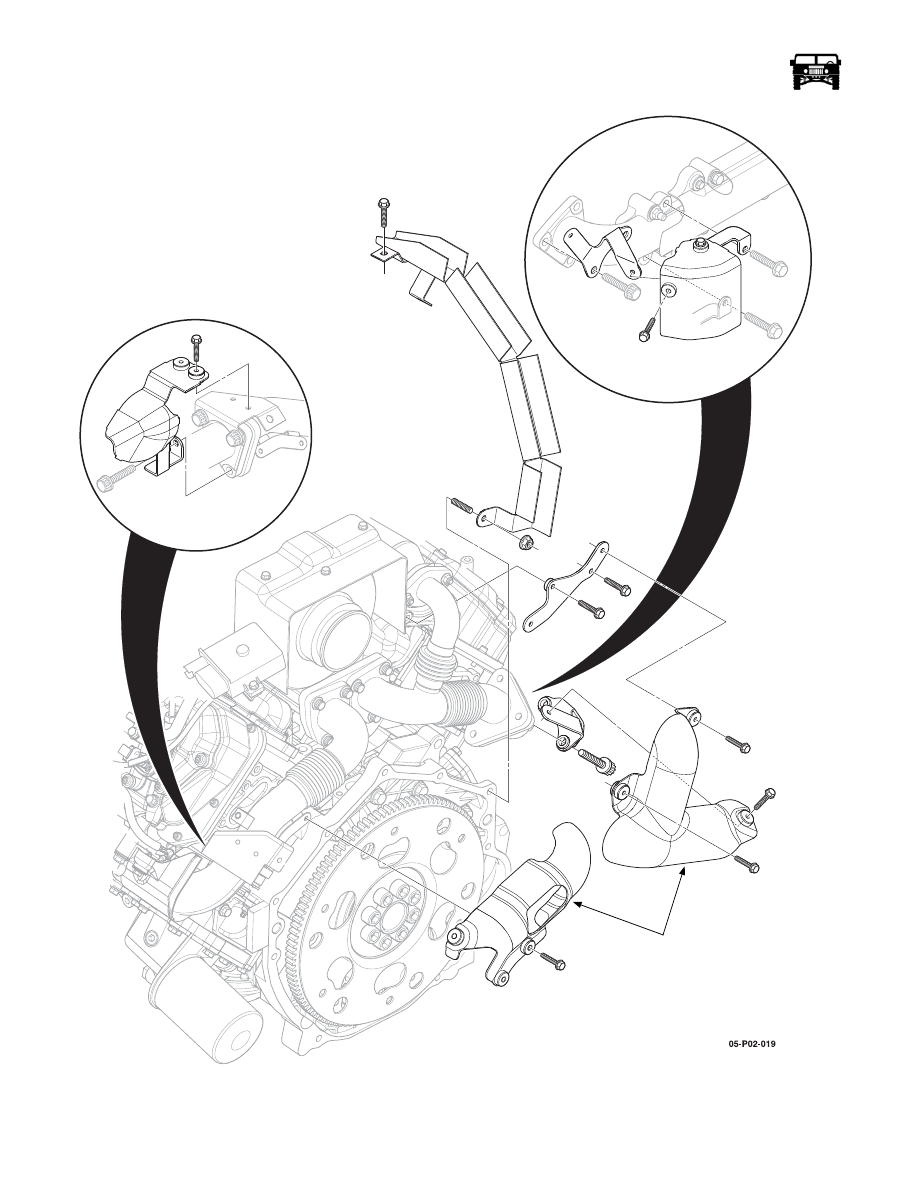

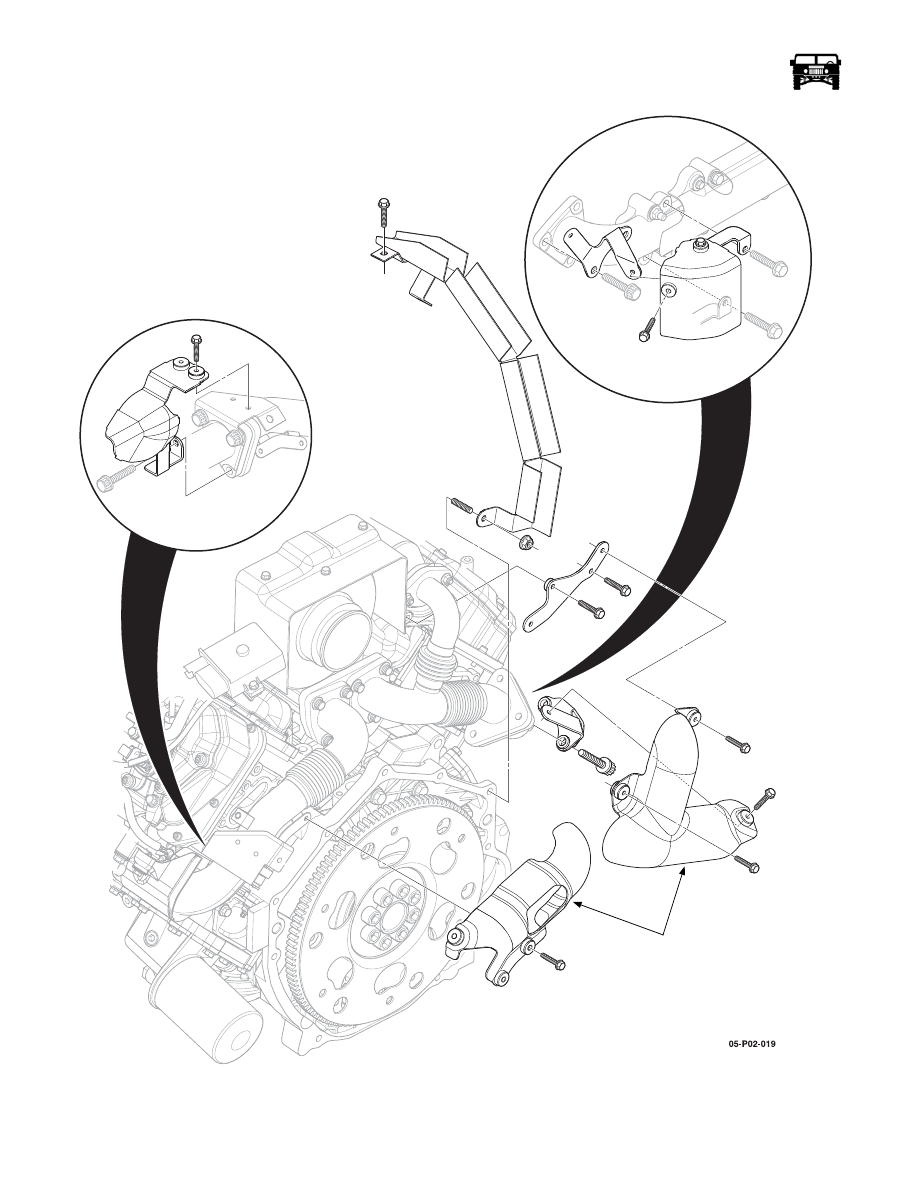

Figure 2-33: Turbo Pipe Heat Shields

TURBO PIPE

HEAT SHEILDS

|

|

|

2-38 Engine ______________________________________________________________________ Figure 2-33: Turbo Pipe Heat Shields TURBO PIPE HEAT SHEILDS |