Hummer H1 (2002+). Manual - part 252

_______________________________________________________________________________

13-1

®

05745159

Section 13 Accessories

TABLE OF CONTENTS

Air Restriction Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-34

Auxiliary Seat

Belt Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-27

Frame Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-28

Locking Pin Replacement . . . . . . . . . . . . . . . . . . . . . . . . .13-28

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-27

Brushguard Assembly Replacement . . . . . . . . . . . . . . . . . . .13-10

Delco Compact Disc Changer Replacement . . . . . . . . . . . . . .13-36

Dual Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-35

Hourmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-30

Off Road Light Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-31

Roof Rack

Clamp Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-26

Crossbar Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .13-25

End Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-25

Running Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .13-21

Seat Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-37

Cargo Deck Mounted . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

Swing-Away . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-10

Trailer Hitch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-20

Trailer Towing Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-19

Underbody Protection

Front Shield Replacement . . . . . . . . . . . . . . . . . . . . . . . . 13-15

Intermediate Shield Replacement . . . . . . . . . . . . . . . . . . 13-16

Rear Shield Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

Skid Plate Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Transfer Case Shield Replacement . . . . . . . . . . . . . . . . . 13-17

Rocker Panel Protection Replacement . . . . . . . . . . . . . . . . . . 13-18

Winch

Assembly Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Electric Thermal Switch/Brush Assembly . . . . . . . . . . . . 13-7

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

WINCH VIN 186477 AND LATER

NOTE:

Individual parts may not be available for some of the

following repair procedures. Assemblies must be used in place

of individual parts. Check for parts availability before disas-

sembly.

Winch Troubleshooting

Winch Inoperative

1.

Check for jammed winch cable.

2.

Check winch control cable connector for corrosion or

loose connection. Clean corroded connector or secure

loose connection.

3.

Check for loose or damaged winch power cables. Using

voltmeter, connect positive meter lead to positive power

cable (red) at the winch motor, and negative meter lead to

the winch motor ground cables (black). If voltage is not

present, repair or replace winch power cables.

4.

Disconnect winch control from winch. Using an

ohmmeter, check for continuity between the common

terminal and the other two terminals on winch control

cable connector. Check for continuity one at a time, while

holding control in the OUT position and the IN position. If

continuity is present in both positions, repair winch. If

continuity is not present in both positions, replace winch

control.

Winch Replacement

Removal

WARNING: To avoid personal injury or damage, sup-

port winch during removal.

1.

Disconnect battery ground cables (Section 12).

2.

Remove two battery cable bolts, battery cables, and winch

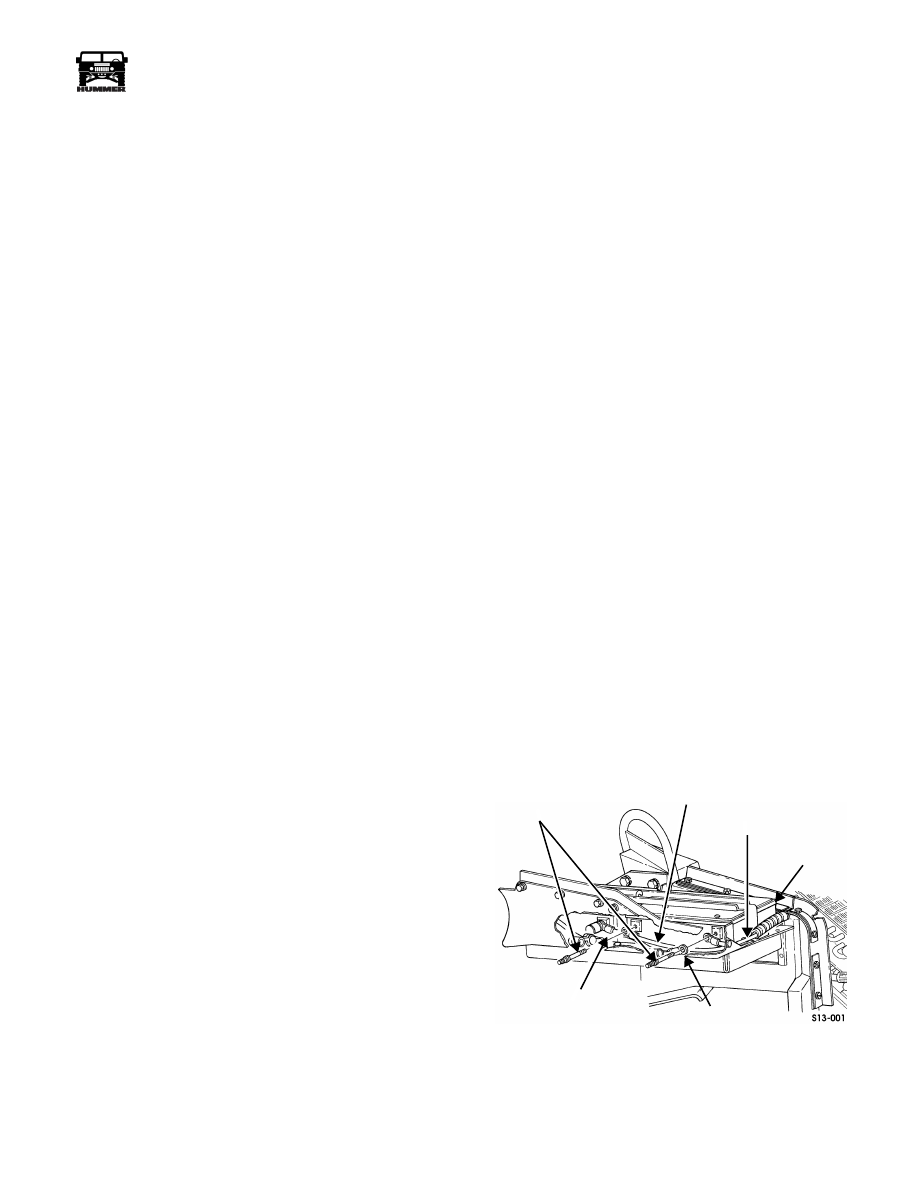

cables from battery (Figure 13-1).

Figure 13-1: Winch Cables On Battery

3.

Remove nut, lockwasher, capscrew, and clamp from right

frame extension. Discard lockwasher. Pull winch cables

through the splash shield to front of vehicle (Figure 13-2).

POSITIVE

BATTERY

NEGATIVE

POSITIVE

BATTERY CABLE

BATTERY

CABLE

WINCH

CABLE

NEGATIVE

WINCH CABLE

BATTERY CABLE

BOLTS