Hummer H1 (2002+). Manual - part 85

___________________________________________

Transmission/Transfer Case 5-139

®

05745159

TORQUE CONVERTER/FLEXPLATE/

CONVERTER SEAL REPLACEMENT

1.

Remove transmission as described in this section.

2.

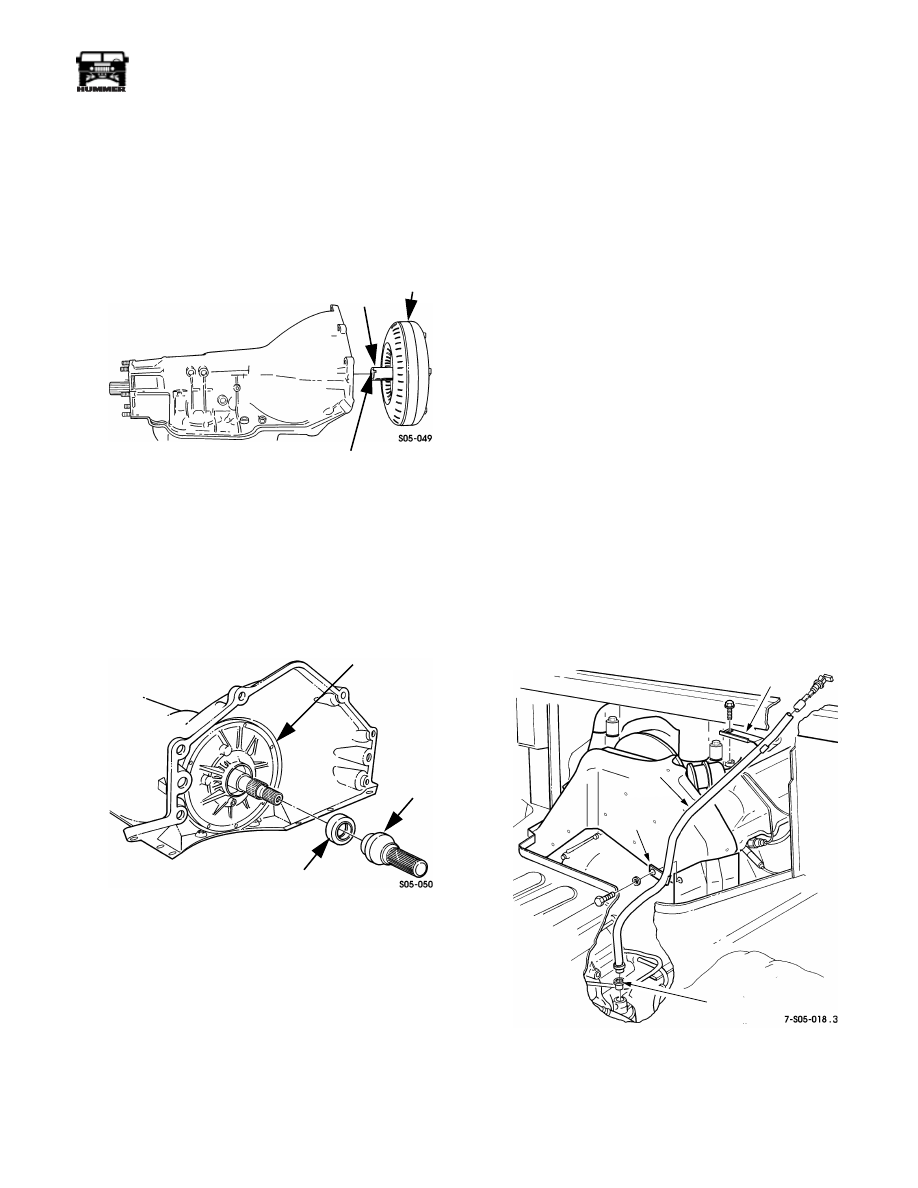

Remove torque converter from transmission (Figure 5-42).

3.

Remove oil seal from pump. Use standard hook tool to

pull seal.

Figure 5-42: Torque Converter Removal/Installation

4.

If flexplate is to be replaced, remove attaching bolts and

remove driveplate.

5.

Position new flexplate on crankshaft flange. Apply 1-2

drops of Loctite 242 to flexplate bolt threads. Then install

and tighten bolts to 65 lb-ft (88 N•m) torque.

Figure 5-43: Oil Pump Seal Installation

6.

Install converter seal with tool J–38694 (Figure 5-43).

7.

Install torque converter. Be sure drive lugs on pump gear

are engaged in drive slots of converter hub (Figure 5-42).

8.

Install transmission as described in this section.

NOTE:

Converter will be recessed in housing when installed

completely and will turn freely when transmission is installed

on engine.

TRANSMISSION REMOVAL

1.

Remove console and engine cover.

2.

Remove bolts attaching transmission fill tube to heat

shield and intake manifold (Figure 5-44). Then remove fill

tube from transmission case. Cover fill tube bore in case to

prevent dirt entry.

3.

Disconnect transfer case shift rod at operating lever

(Figure 5-45).

4.

Disconnect transmission shift rod trunnion from shift

control arm (Figure 5-46).

5.

Disconnect speed sensor and lock indicator switch wires at

rear of transfer case (Figure 5-47). Then disconnect range

switch at front of transfer case (Figure 5-48).

6.

Remove clamps securing wire harness to transfer case and

transmission.

7.

Disconnect vent lines at transmission and transfer case.

8.

Disconnect transmission harness at case connector by

squeezing both lock tabs of harness connector, and pulling

it straight out of case connector.

CAUTION:

Do not pull, twist, pry, or rotate the harness con-

nector in an attempt to remove it. This action can damage the

connector body, pin terminals and solder joints. Release only

by squeezing the lock tabs (Figure 5-49).

9.

Disconnect harness wires at transmission input speed

sensor (Figure 5-50).

Figure 5-44: Fill Tube Attachment

HUB

SLOTS

TORQUE

CONVERTER

OIL PUMP

CONVERTER SEAL

SEAL

J–38694

INSTALLER

FILL TUBE

SEAL

BRACKET

BRACKET

FILL

TUBE