Hummer H1 (2002+). Manual - part 46

___________________________________________

Fuel, Emissions, and Exhaust 3-45

®

5745159

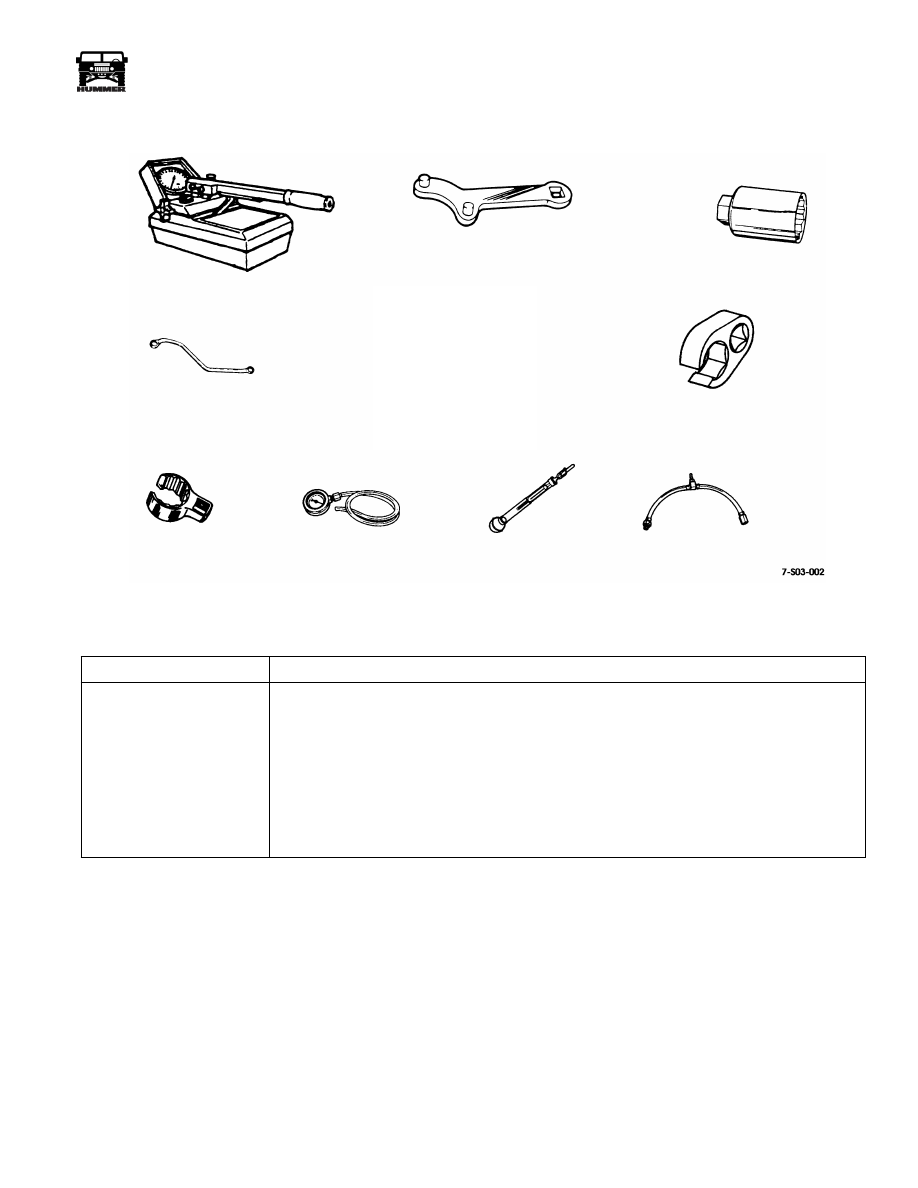

ESSENTIAL TOOLS

Procure from Kent-Moore.

Tool No.

Description

J–29075-AMG

Fuel Injector Pressure Test Tool

J–29872-A

Injection Pump Adjusting Tool (used with ratchet handle)

J–29873

Fuel Injector Socket (30mm)

J–29698-A

Injection Line (flare nut) Wrench, 3/4

J–28552-A

Fuel Pressure Gauge

J–38641-B

Diesel Fuel Hydrometer

J–34151

Housing Pressure Adapter

J–41711

Injection Pump Timing Wrench, 6.5 Turbo (not shown)

J–28552-100

Adapter, Fuel Line

J–29075-AMG

J–29872-A

J–29873

J–41089

J–29079-125

J–41516-A

J–29698-A

J–28552-A

J–38641-B

J–34151