Hummer H1 (2002+). Manual - part 16

____________________________________________________________________

Engine 2-25

¨

05745159

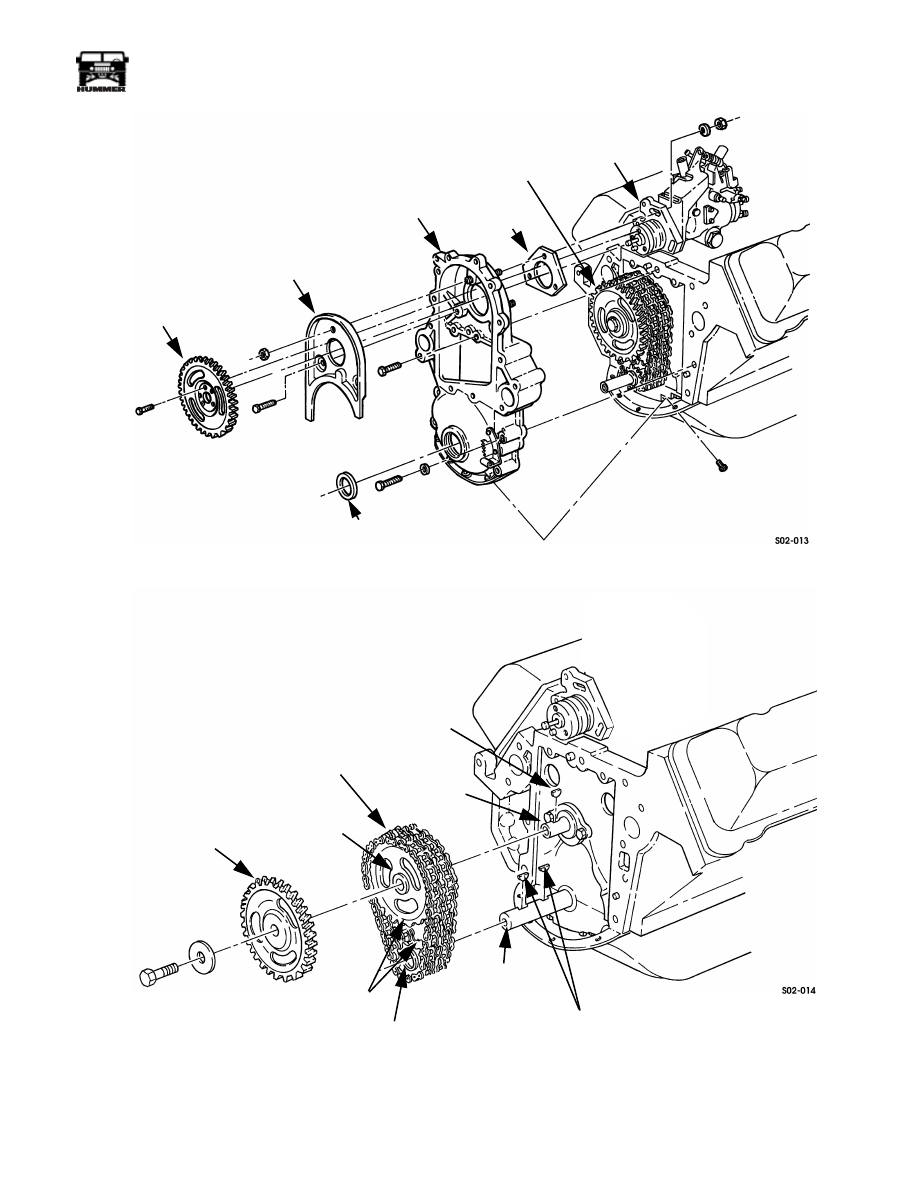

Figure 2-24: Drive Gear, Baffle, and Front Cover Removal

Figure 2-25: Drive Gear, Timing Chain, and Sprocket Removal

FRONT

SEAL

BAFFLE

INJECTION

PUMP

DRIVEN

GEAR

FRONT

COVER

PUMP

GASKET

FUEL

PUMP

INJECTION

PUMP

DRIVE

GEAR

INJECTION

INJECTION PUMP

DRIVE GEAR

CAMSHAFT

TIMING CHAIN

CAMSHAFT KEY

CAMSHAFT

CRANKSHAFT

CRANKSHAFT KEYS

CRANKSHAFT

SPROCKET

TIMING MARKS

SPROCKET