Great Wall Florid. Manual - part 2

GWFLORID Maintenance Manual

6

2. Inspection procedures for related fuses or fuses in re-

Inspection procedures for related fuses or fuses in re-

Inspection procedures for related fuses or fuses in re-

lay boxes. Inspect the battery for damage, the battery's

charging state, cleanness, and tightening with the

connectors.

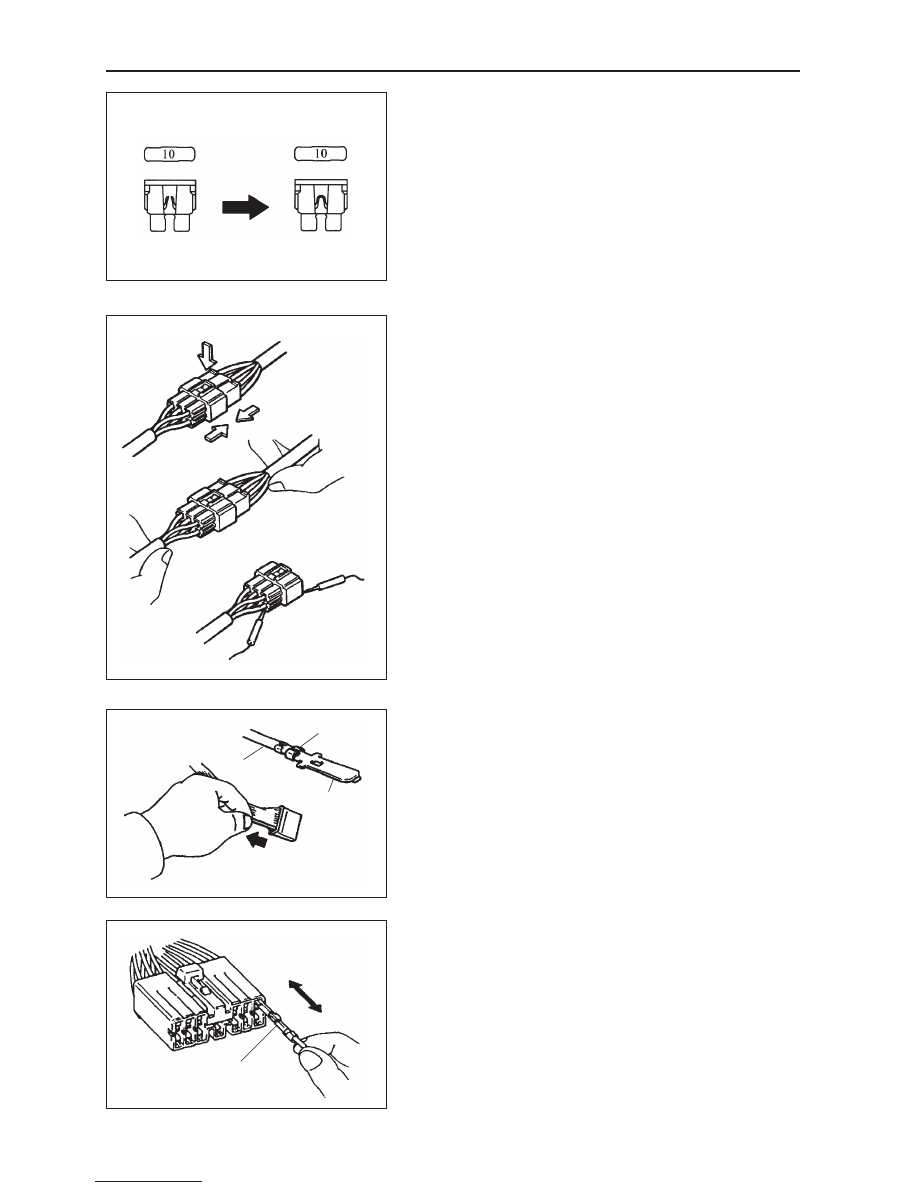

Before changing a fuse, make sure to check if the fuse's cur-

rent rating meets the required standards. You must not use a

fuse with a current rate that is higher or lower than required

standards.

Same current rating

3. Binding wire harness connectors.

(a) When disconnecting the connections, first press the two

ends of the connectors together, then loosen the lock

and press the lock pawl to release the connector.

(b) When disconnecting the connector, do not pull on its

wire harness. Grasp the joint directly.

(c) Check if the joint is deformed, damaged, or port lost

before connecting the connector.

(d) The connector is not successfully connected until it

makes a click sound.

4. Wire harness connector inspection.

(a) Check while connecting the connectors.

Squeeze both ends of the connectors to make sure it is com-

pletely plugged in and tightly locked.

(b) Check when disconnecting the connectors.

Check by lightly pulling the wire harness behind the connec-

tor's joint. Look for any unconnected or dropped terminals,

loose clamps, or broken wires.

Visually inspect for instances of corrosion, metal fragments,

oddities, and water, as well as bending, rust, overheating,

pollution or deformed terminals, etc.

(c) Check the contact pressure of the terminals.

Prepare a plug that matches the connector's port, plug it into

the socket, then check for the proper rate of tension after

they are fully engaged.

Loosen crimp

Core

Deformed terminal

Pull lightly

The terminal is similar to a plug

Incorrect