Content .. 1530 1531 1532 1533 ..

Ford F150 Pickup. Instruction - part 1532

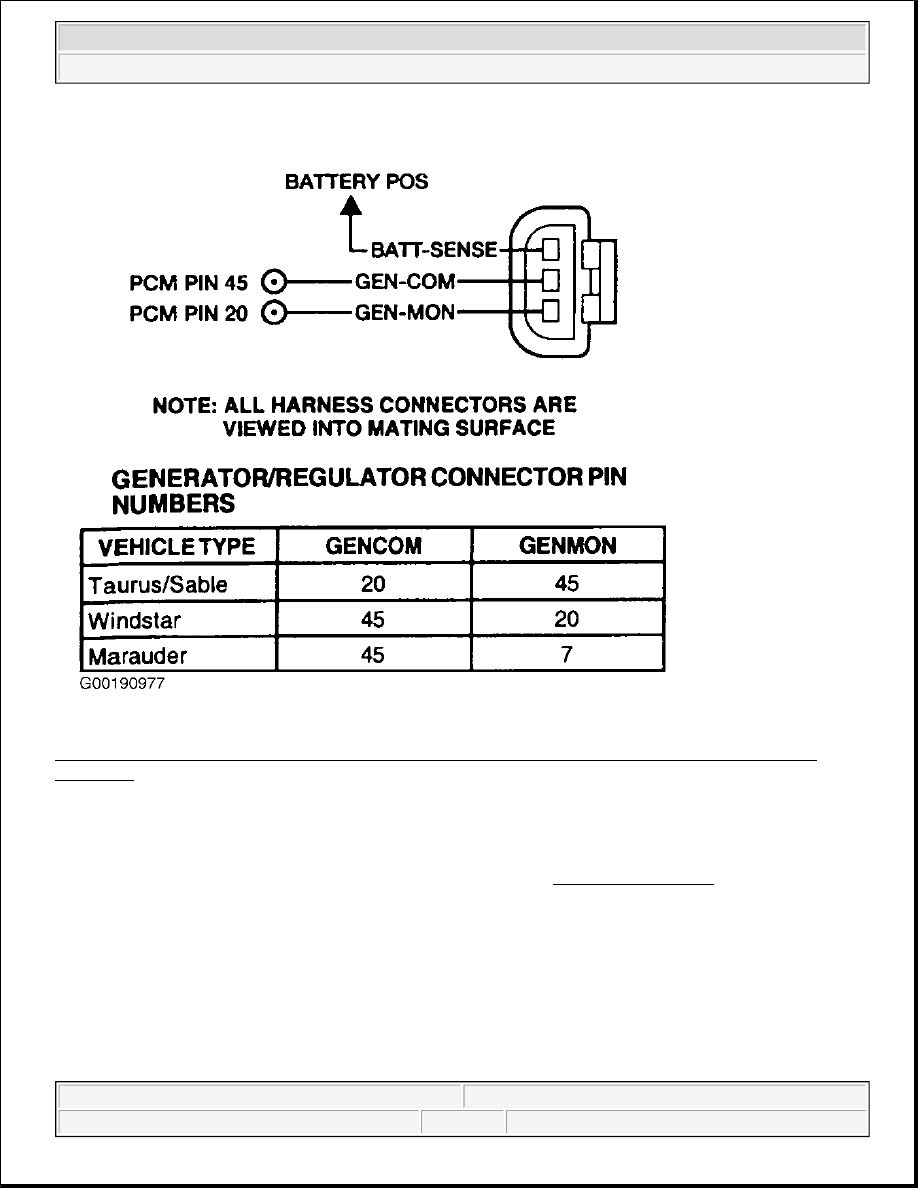

Fig. 278: Identifying Generator Wiring Harness Connector Terminals (Marauder, Sable, Taurus &

Windstar)

Courtesy of FORD MOTOR CO.

Testing

1) For KOER & Continuous Memory Only DTCs P0622, P1244, P1245 & P1246: Verify Generator

Drive Function

The PCM monitors generator load from the generator/regulator in the form of frequency. The frequency

range is determined by the temperature of the voltage regulator where 97 percent represents full load,

below 6 percent means no load. Possible causes are:

z

Generator circuit short to GND.

z

Generator circuit short to PWR.

NOTE:

For additional testing information, see DIAGNOSTIC AIDS.

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Self-Diagnostics - CNG, Flex-Fuel & Gasoline