Content .. 1509 1510 1511 1512 ..

Ford F150 Pickup. Instruction - part 1511

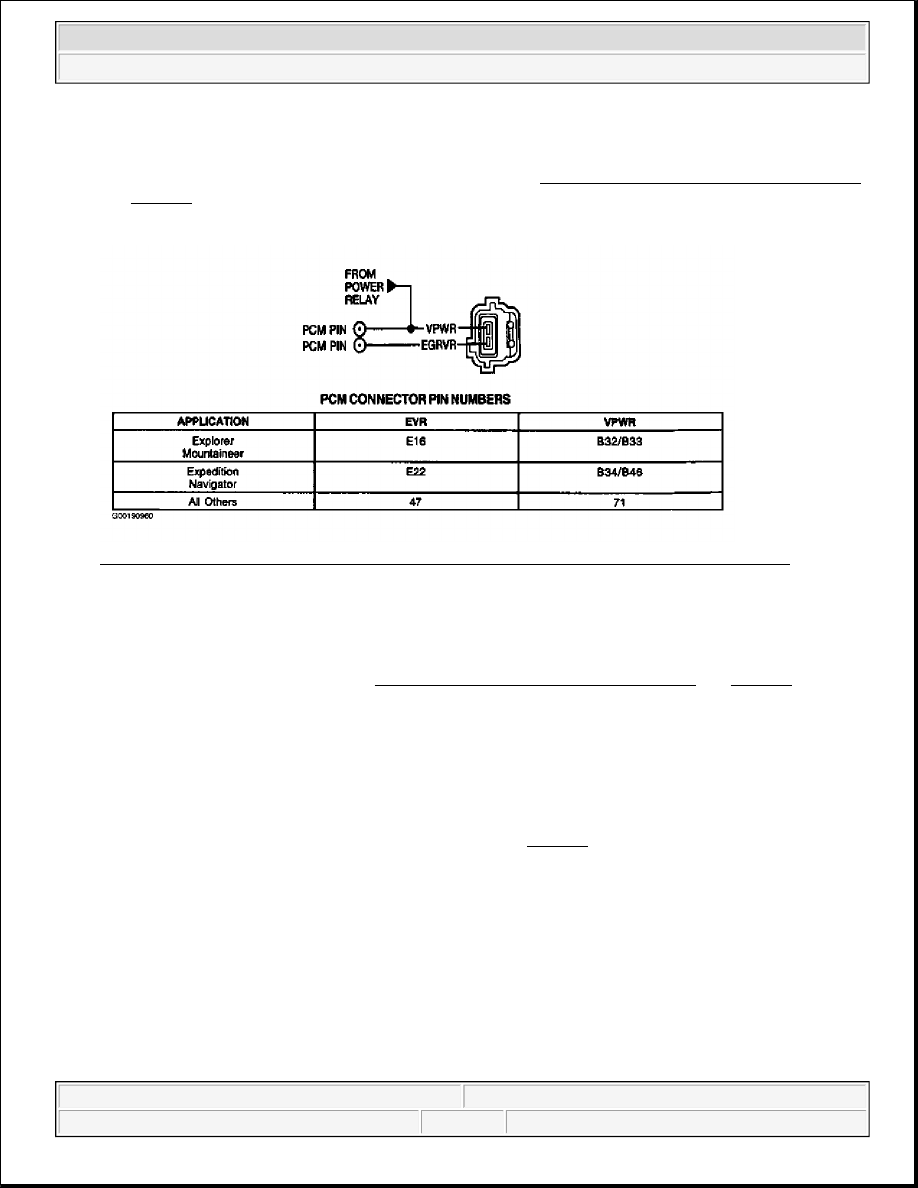

Disconnect scan tool from DLC. Disconnect PCM connector(s). Inspect connector for loose, damaged or

corroded terminals. Repair as necessary. Using a DVOM, measure resistance between negative battery

terminal and EGRVR circuit at PCM harness connector. See PCM CONNECTOR IDENTIFICATION

and Fig. 244. If resistance is more than 10 k/ohms, go to next step. If resistance is 10 k/ohms or less,

repair short to ground in EGRVR circuit.

Fig. 244: Identifying EGRVR Solenoid Wiring Harness Connector Terminals (All Others)

Courtesy of FORD MOTOR CO.

30) Check EGRVR Circuit For Short To VREF

Using a DVOM, measure resistance between EGRVR and VREF circuits at PCM harness connector (both

VREF circuits on 150-pin PCM). See PCM CONNECTOR IDENTIFICATION and Fig. 244. If

resistance is more than 10 k/ohms, replace PCM. If resistance is 10 k/ohms or less, repair short between

EGRVR and VREF circuits.

31) Check DPFEGR Sensor Output By Applying Vacuum With Hand Pump

Turn ignition switch to OFF position. Connect scan tool to Data Link Connector (DLC). Disconnect

pressure hoses at DPFEGR sensor. Connect hand vacuum pump to downstream connection at DPFEGR

sensor (intake manifold side or smaller diameter port). See Fig. 239. Using scan tool, access DPFEGR

PID from PID/DATA MONITOR & RECORD menu. Read the following DPFEGR PID values with

ignition switch in ON position:

z

DO NOT apply vacuum to sensor. Record DPFEGR PID value. DPFEGR PID value should be .2-

1.3 volts.

z

Using vacuum pump, apply 8-9 in. Hg (27-30 kPa) for a few seconds. DPFEGR PID value should

increase to more than 4 volts.

z

Quickly release vacuum. DPFEGR PID value should drop to less than 1.5 volts within 3 seconds of

releasing vacuum.

If any DPFEGR PID values are not as specified, replace DPFEGR sensor. If all DPFEGR PID values are

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Self-Diagnostics - CNG, Flex-Fuel & Gasoline