Content .. 1504 1505 1506 1507 ..

Ford F150 Pickup. Instruction - part 1506

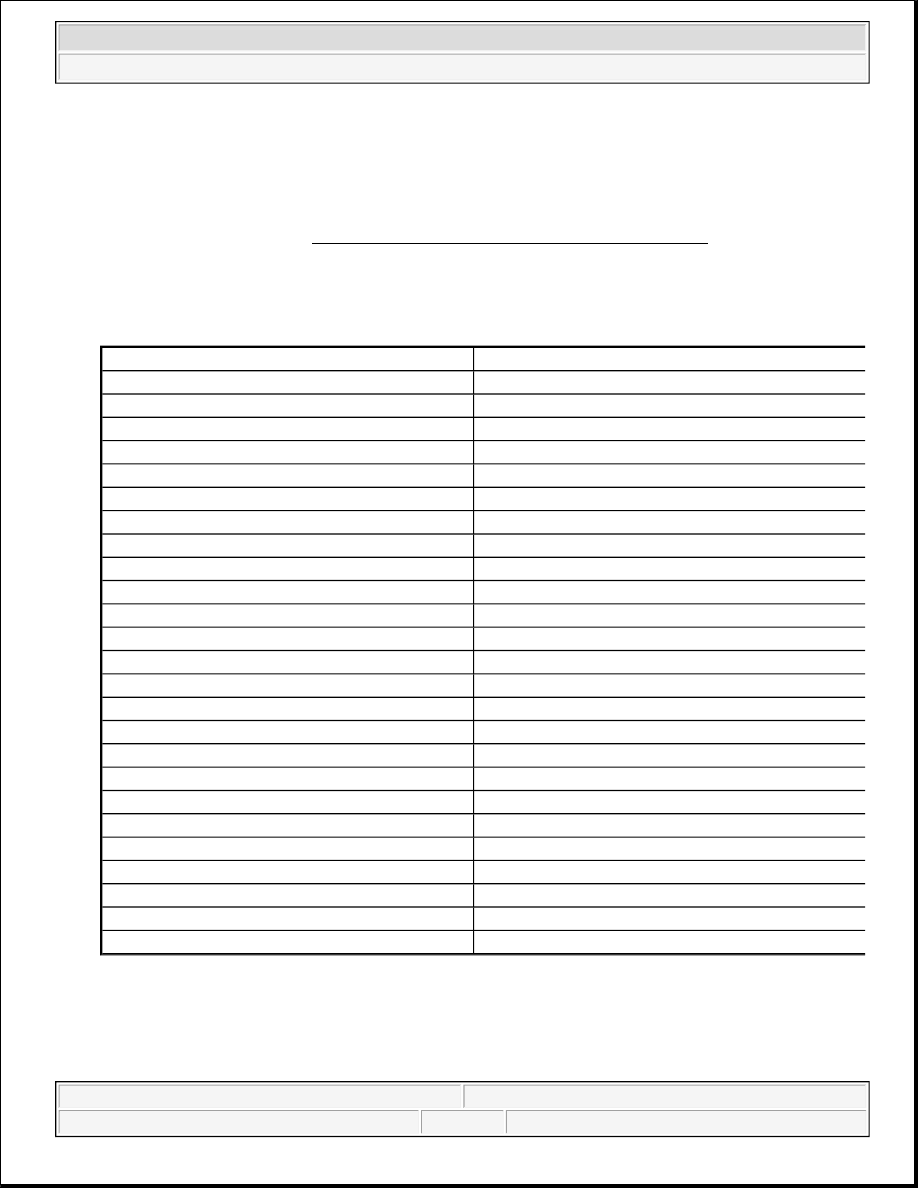

Connect scan tool to Data Link Connector (DLC). Place gearshift lever in "P" position. Start engine and

allow to idle. Using scan tool, access TANKPR PID from NGVM PID/DATA MONITOR & RECORD

menu. Record TANKPR PID value. Using scan tool, access FRP PID from PCM PID/DATA MONITOR

& RECORD menu. Record FRP PID value. Locate approximate TANKPR PID value and determine

PCM inferred pressure using PCM INFERRED PRESSURE SPECIFICATIONS table. If PCM

inferred pressure is plus or minus 22 psi of FRP PID value, no concern is indicated at this time. Service

any other DTCs that are present. If PCM inferred pressure is not plus or minus 22 psi of FRP PID value,

go to next step (for DTC P1180), or replace fuel pressure regulator (for DTC P1181).

PCM INFERRED PRESSURE SPECIFICATIONS

19) Check Fuel Filter For Water Or Other Contamination

Disassemble fuel filter and check for water or any other contamination. If contamination is present, clean

contaminants from filter housing and replace filter. If no contamination is present, go to next step.

TANKPR PID Value - kPa

PCM Inferred Pressure - psi

2000

109

3000

108.4

4000

106.9

5000

106.5

6000

106

7000

105.6

8000

105

9000

104.5

10,000

103.4

11,000

103

12,000

102.5

13,000

102.3

14,000

101.8

16,000

100.8

17,000

99.8

18,000

99.3

19,000

99

20,000

98.5

21,000

97.5

22,000

97.3

23,000

96.3

24,000

96

26,000

96

28,000

95.5

30,000

94

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Self-Diagnostics - CNG, Flex-Fuel & Gasoline