Content .. 1340 1341 1342 1343 ..

Ford F150 Pickup. Instruction - part 1342

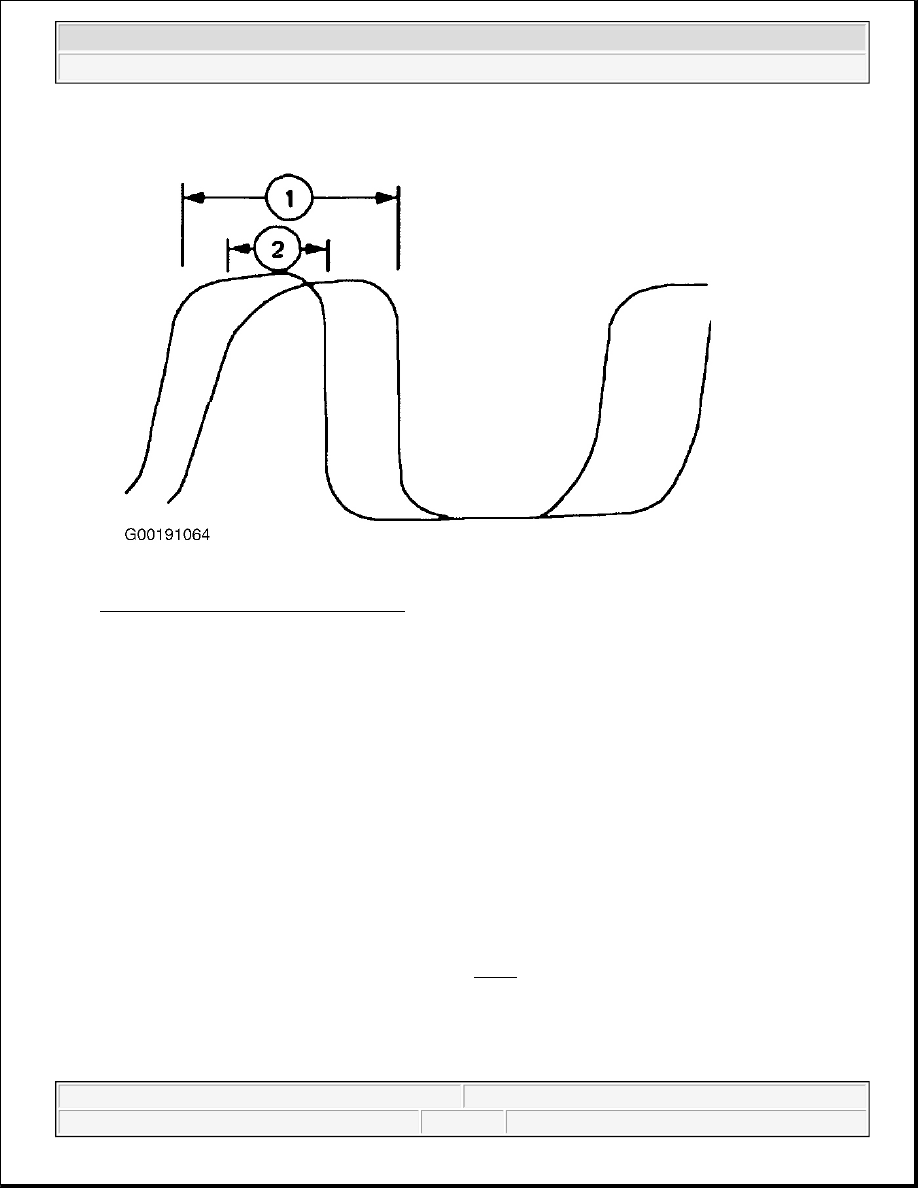

Fig. 4: Identifying HO2S Signal Display

Courtesy of FORD MOTOR CO.

11. Use an assistant in the driver seat to repeat step 6 . Obtain and hold the "tuning point" vacuum value.

12. Select the NGS GRAPH option and record ten seconds of data from PCM PIDs O2S11 and O2S21.

Allow the accelerator to return to the idle position and place the transmission in the Park position.

13. Retrieve the recorded data and identify which of the OS2 signals displays the longest high state time as in

step 10 .

14. Determine which of the tuning tee adjustment screws requires adjustment. This is the only screw to be

adjusted throughout the entire tuning tee procedure and is determined by the following: The PCM PID

O2S11 data reflects the upstream bank 1 O2S and is adjusted with the passenger side tuning tee

adjustment screw (1). The PCM PID O2S21 data reflects the upstream bank 2 O2S and is adjusted with

the driver side tuning tee adjustment screw (2). See Fig. 3 . To reduce the PCM PID O2S11 or O2S21

high state time the corresponding adjustment screw is turned clockwise and to increase the high state time

the adjustment screw is turned counterclockwise.

15. Turn the tuning tee adjustment screw identified in step 13 one complete turn clockwise and repeat steps

10 through 12 .

WARNING:

This step requires two people while the vehicle is running, in gear,

and the engine accelerated. Be sure that the parking brake is fully

set and the wheels are correctly chocked. Take all necessary

precautions to avoid injury and property or equipment damage.

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE System & Component Testing - Bi-Fuel - Gasoline/LPG