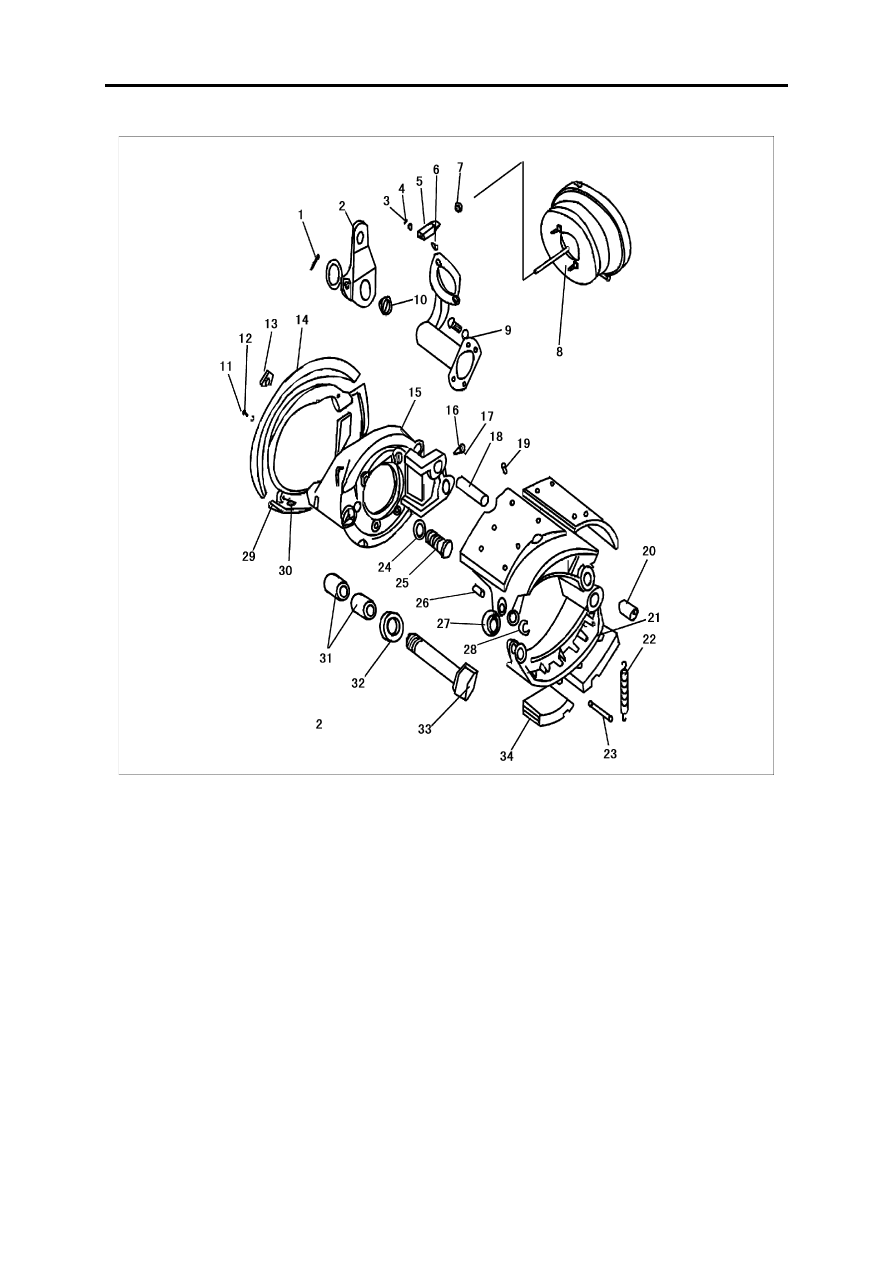

Dongfeng DFA1063DJ10 (14)-301/303. Manual - part 18

Rear Axle

RA-2

Disassembly of the brake

1.Cotter pin

2. Brake adjusting arm

3.Cotter pin

4.Plain washer

5.U-fork

6.Flat pin

7.Locking nut

8.Spring air chamber

9.Air chamber bracket

10.Cam ring cage ring

11.Bolt

12.Spring washer

13.Rubber plug

14.Dustproof shield

15.Brake bottom plate

16.Set screw

17.Steel lock wire

18.Supporting pin

19.Rivet

20.Brake bush

21.Brake shoe

22.Return spring

23.Return spring pin

24.Spring washer

25.Screw

26.Roller pin shaft

27.Roller

28.Clamp ring

29.Dustproof shield

30.Grease nipple

31.Bush

32.Oil seal

33.Cam shaft

34.Brake friction plate