Dongfeng DFA1063DJ10 (14)-301/303. Manual - part 4

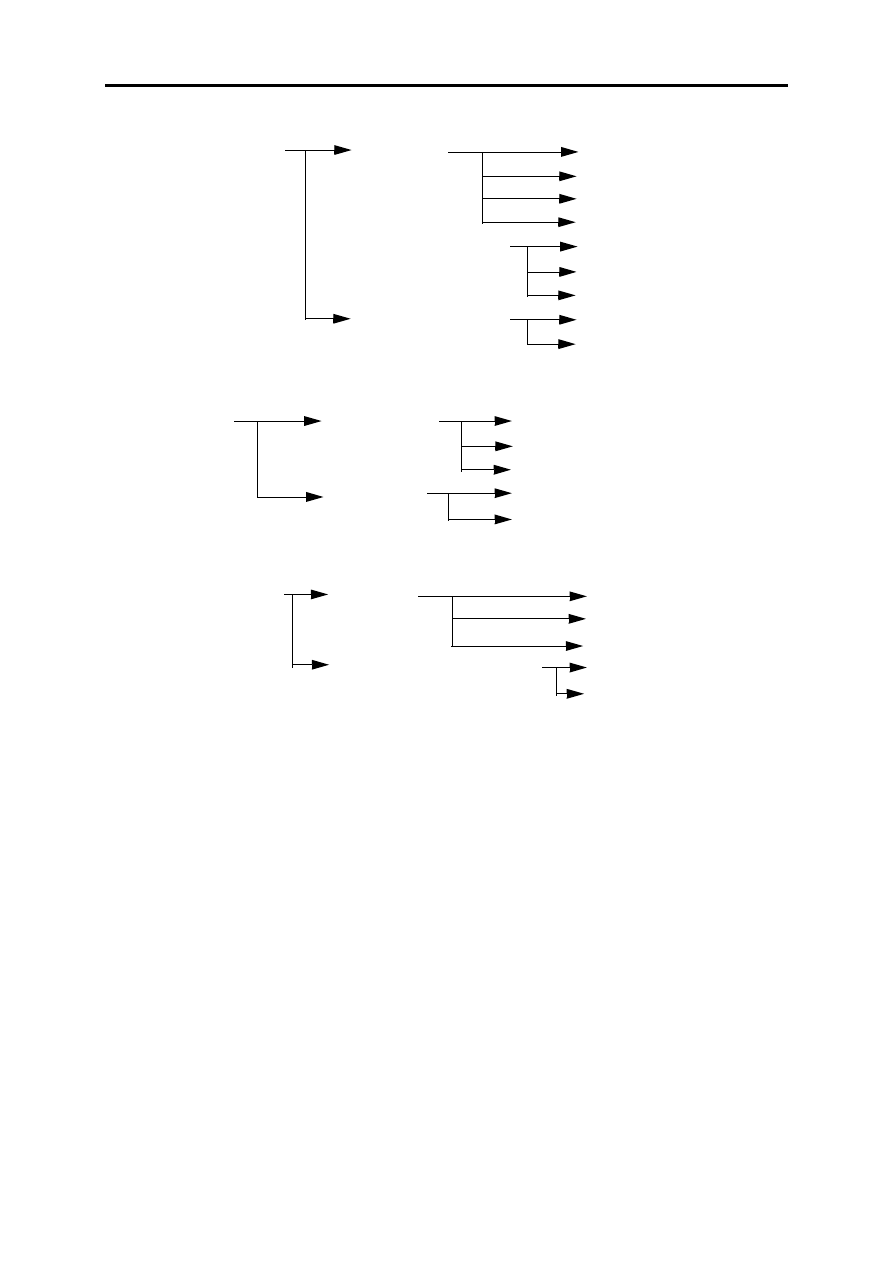

General Principles

GL-12

Abnormal steering operation

Heavy steering

Steering system troubled

Incorrect front wheel alignment

Front axle troubled

Over low pressure of front wheel

Turning wheels not return

Steering system troubled

Incorrect front wheel alignment

Front axle troubled

Insufficient steering angle

Steering system troubled

Front axle troubled

Abnormal gear shift

Difficult gear shift

Abnormal clutch disengagement

Transmission troubled

Transmission handling mechanism troubled

Gear disengaged

Transmission troubled

Transmission handling mechanism troubled

Abnormal braking operation

Weak braking

Brake system troubled

Overwear of tyres

Hub bearing clearance too large

Brake can't be released completely

Brake system troubled

Hub bearing clearance too large