Dongfeng DFA1101GZ5AD6J-907. Manual - part 29

Clutch

CL-7

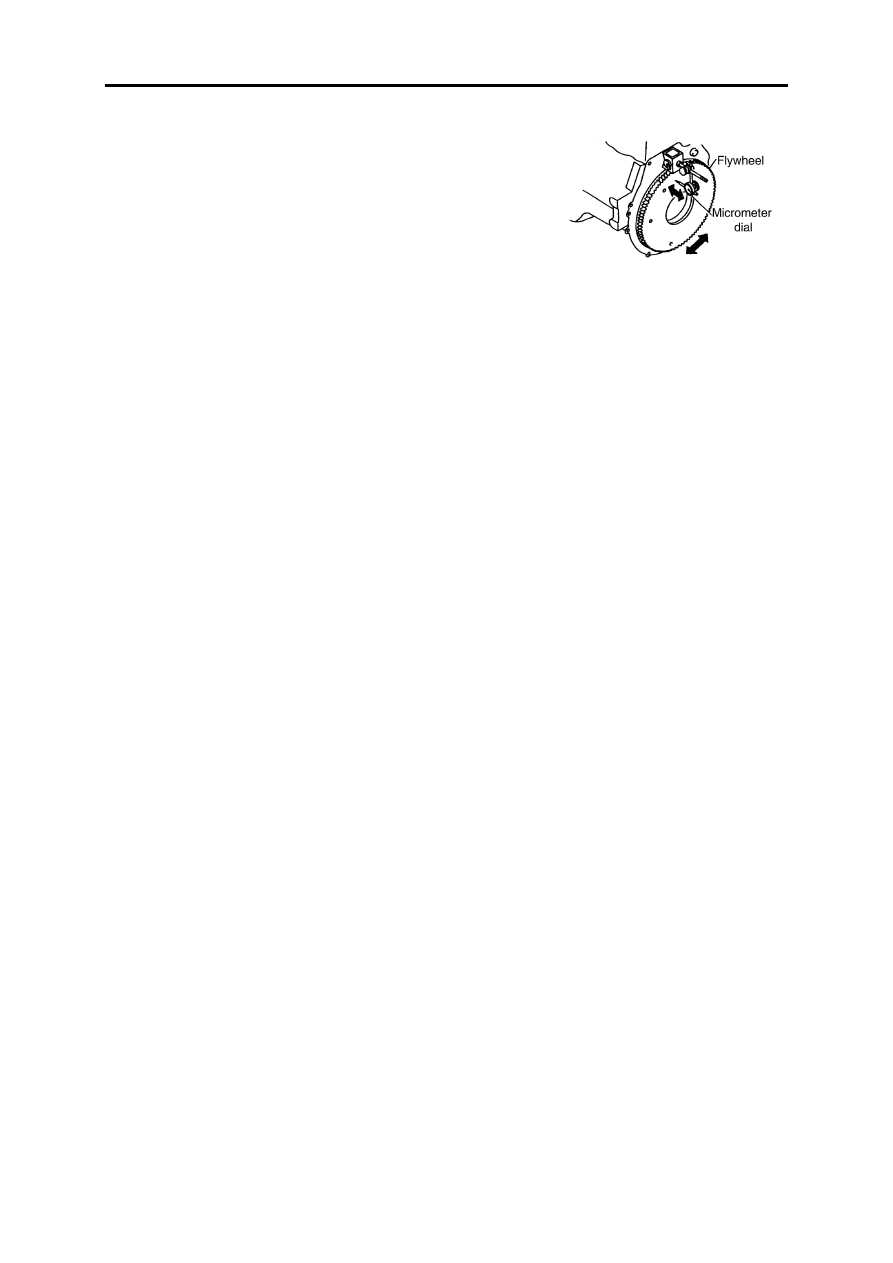

Flywheel check

Check the working face of the flywheel for ablation or color changed,

make use of the corundum paper to get rid of them if necessary.

Check the plainness of the flywheel surface: <0.1mm

Usage and Maintenance

The diaphragm clutch which has two positioning holes and been con-

nected by 8 M10 bolts, is made up by cover assy and driven disc assy.

The drive blade is used to transmit the engine torque between the

pressure plate and clutch cover. Two ends of the drive blade are riveted to

the clutch cover and the pressure plate. When disengaged, the drive blade

may have the axial deformation, and there is no friction between clutch

cover and pressure plate. Therefore, the clutch will has a higher drive effi-

ciency, lower noise, and stable engage.

The working pressure force is caused by the diaphragm. The original

height of the clutch release finger is 56±1mm. During the usage, it will be

heigher because of wearing. The wear limit of the two pieces of the

friction lining is 2×1.8mm. During the wearing time, the distance between

the toppest point of the release finger and the release bearing end has to be

adjusted to 3~4mm, and the largest release stroke of the release finger is

10mm.

The outside diameter of the driven disc friction lining isΦ325mm. Its

material may adopt to asbestos or non-asbestos according to the need of

the customer. The original thickness of the driven disc working surface is

9.7±0.3mm. The assembly is equipped with big and small shock-absorber

spring and damping spacer which is good to absorb the impact and

vibration from the chassis.

The involute spline is used to connect the driven disc and

transmission.

The working surface of the driven disc can't be stained with oil soil

during the assembling and storage.

When the friction lining is in trouble, such as the rivet loose or come

out or cracked, the driven disc must be replaced immediately.

During the assembling and instorage, the working surface of the

clutch cover assembly must haven't any scuffing and rust. If the release

finger is broken or the pressure plate reached to its wear limit and the

diaphragm is broken, you must replace the assembly immediately.