Dodge Nitro. Manual - part 778

RECEIVER/DRIER-A/C

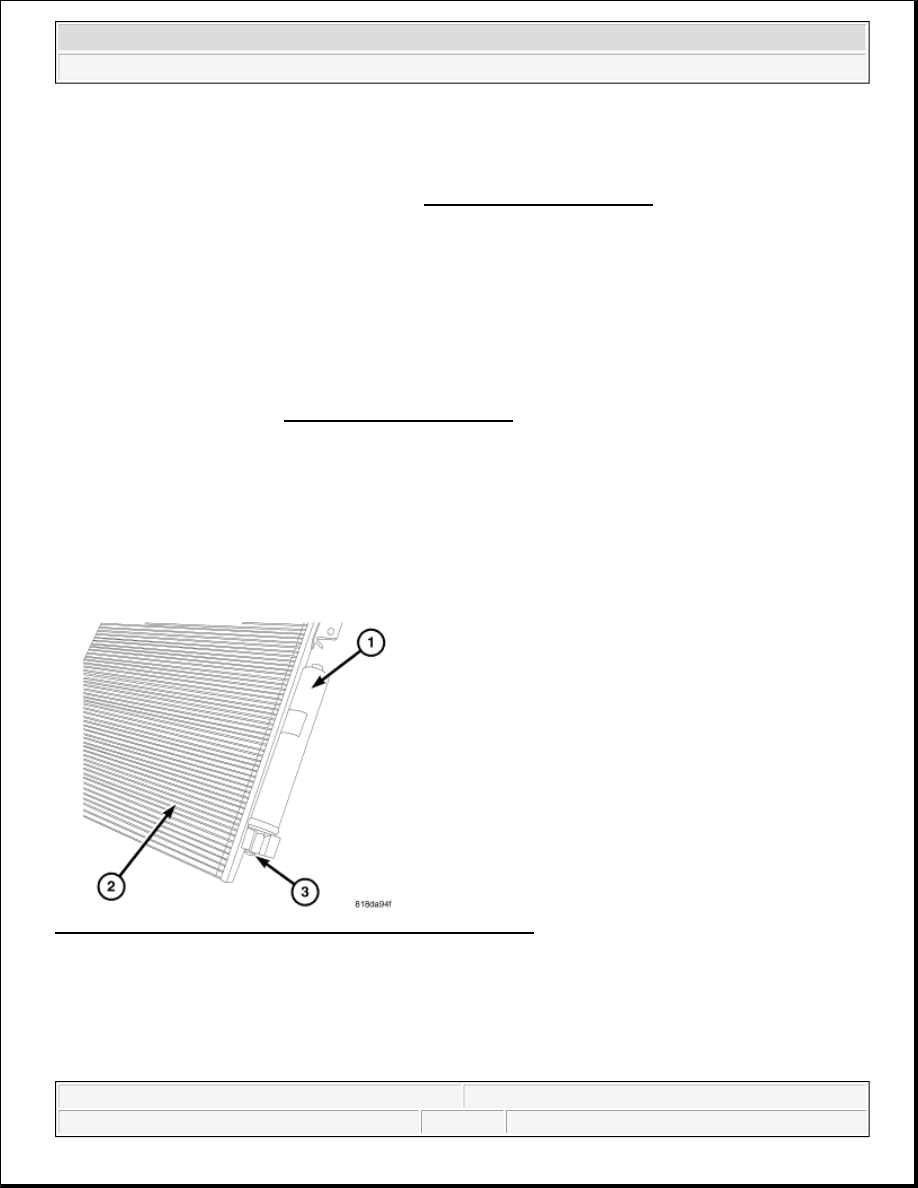

Fig. 200: A/C Receiver/Drier, Left Side A/C Condenser & Bolt

Courtesy of CHRYSLER LLC

1. Remove the tape or plugs from the receiver/drier fittings and the condenser ports.

2. Lubricate new O-ring seals with clean refrigerant oil and install them onto the receiver/drier fittings. Use

CAUTION: Be certain to adjust the refrigerant oil level when servicing the A/C

refrigerant system. See REFRIGERANT OIL LEVEL. Failure to properly

adjust the refrigerant oil level will prevent the A/C system from operating

as designed and can cause serious A/C compressor damage.

CAUTION: The receiver/drier must be replaced if an internal failure of the A/C

compressor has occurred. Failure to replace the receiver/drier can cause

serious A/C compressor damage.

NOTE:

When replacing multiple A/C system components, refer to the Refrigerant Oil

Capacities chart to determine how much oil should be added to the refrigerant

system. See REFRIGERANT OIL LEVEL.

NOTE:

If only the receiver/drier is being replaced, add 30 milliliters (1 fluid ounce) of

refrigerant oil to the refrigerant system. Use only the refrigerant oil of the type

recommended for the A/C compressor in the vehicle.

NOTE:

Replacement of the refrigerant line O-ring seals and gaskets is required anytime

a refrigerant line is opened. Failure to replace the rubber O-ring seals and metal

gaskets could result in a refrigerant system leak.

NOTE:

Illustration shown with A/C condenser removed from vehicle for clarity.

2007 Dodge Nitro R/T

2007 HVAC Heating & Air Conditioning - Service Information - Nitro