Dodge Nitro. Manual - part 585

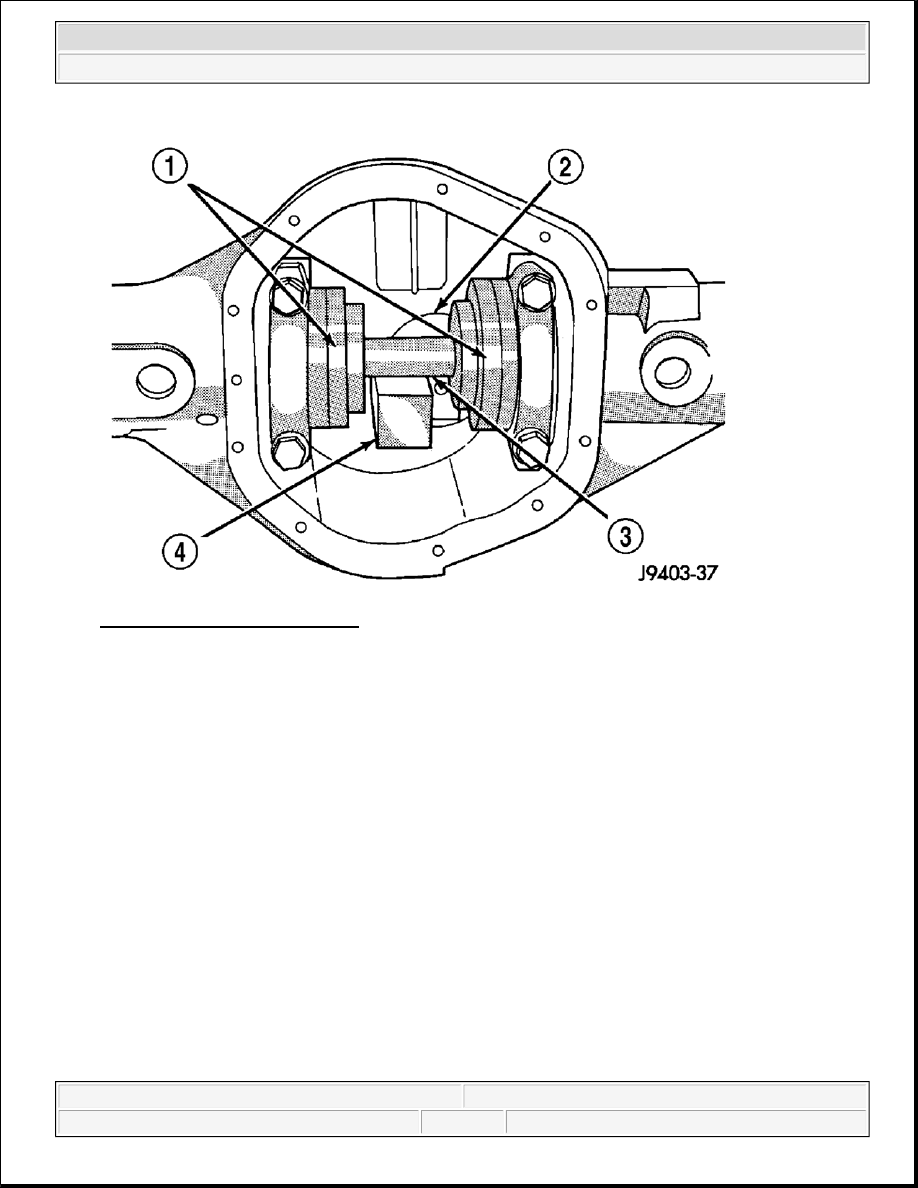

Fig. 227: Gauge Tools In Housing

Courtesy of CHRYSLER LLC

3. Install front pinion bearing and Cone-Nut 6740 on the screw. Tighten Cone-Nut until Torque To Rotate

screw is 1.7 N.m (15 in. lbs.).

4. Place Arbor Disc 8541 (1) on Arbor D-115-3 (3) in position in the housing side bearing cradles. Install

differential bearing caps on arbor discs and tighten cap bolts to 41 N.m (30 ft. lbs.).

2007 Dodge Nitro R/T

2007 DRIVELINE Differential & Driveline - Nitro