Dodge Nitro. Manual - part 506

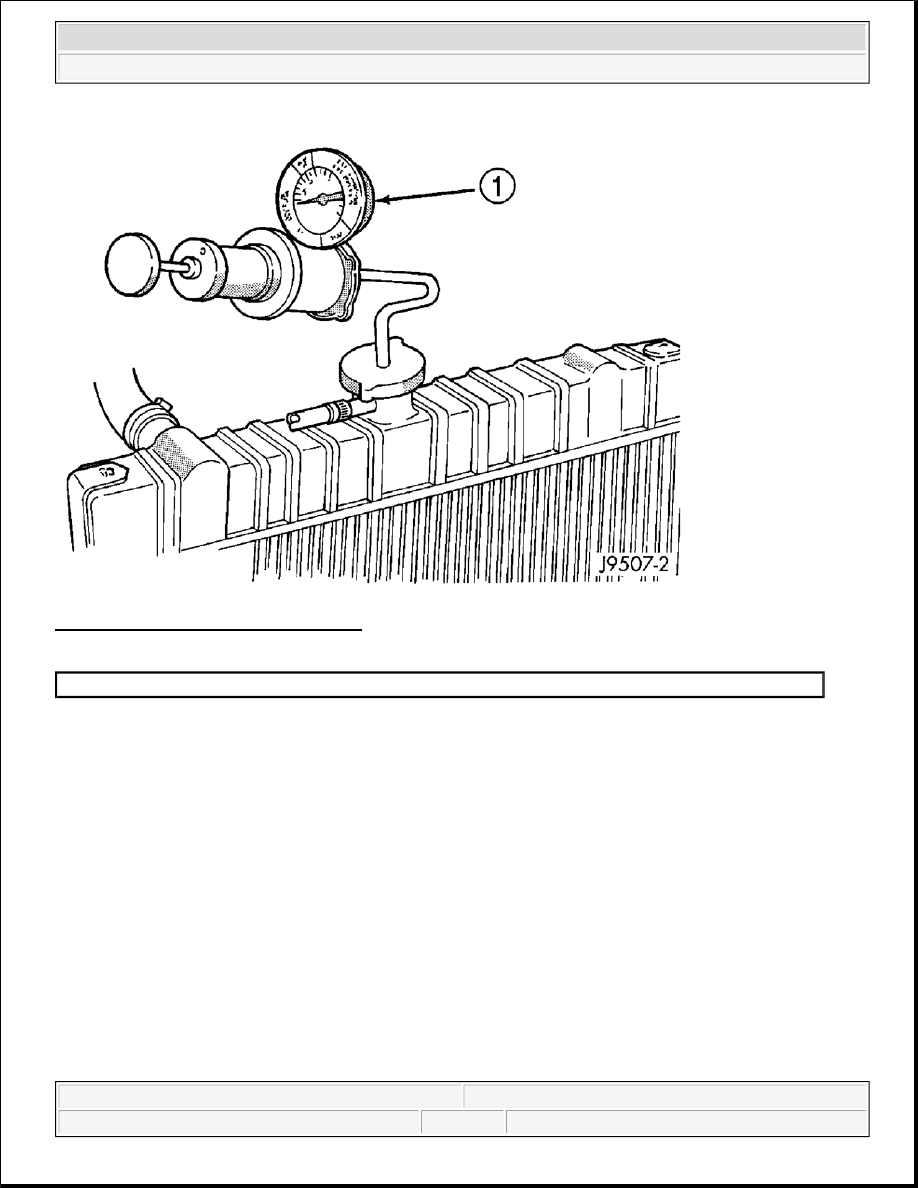

Fig. 3: Pressure Testing Cooling System

Courtesy of CHRYSLER LLC

The engine should be at normal operating temperature. Recheck the system cold if cause of coolant loss is not

located during the warm engine examination.

Carefully remove radiator pressure cap from pressure bottle and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck and examine lower inside sealing seat for nicks, cracks,

paint, and dirt. Inspect radiator-to- reserve/overflow tank hose for internal obstructions. Insert a wire through

the hose to be sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are damaged, seating of pressure cap valve and tester seal will be

affected.

Attach pressure tester (7700 or an equivalent) to radiator filler neck.

Operate tester pump (1) to apply 110 kPa (16 psi) pressure to system. If hoses enlarge excessively or bulges

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WARNING:

Hot, pressurized coolant can cause injury by scalding.

2007 Dodge Nitro R/T

2007 ENGINE Cooling - Nitro