Dodge Nitro. Manual - part 365

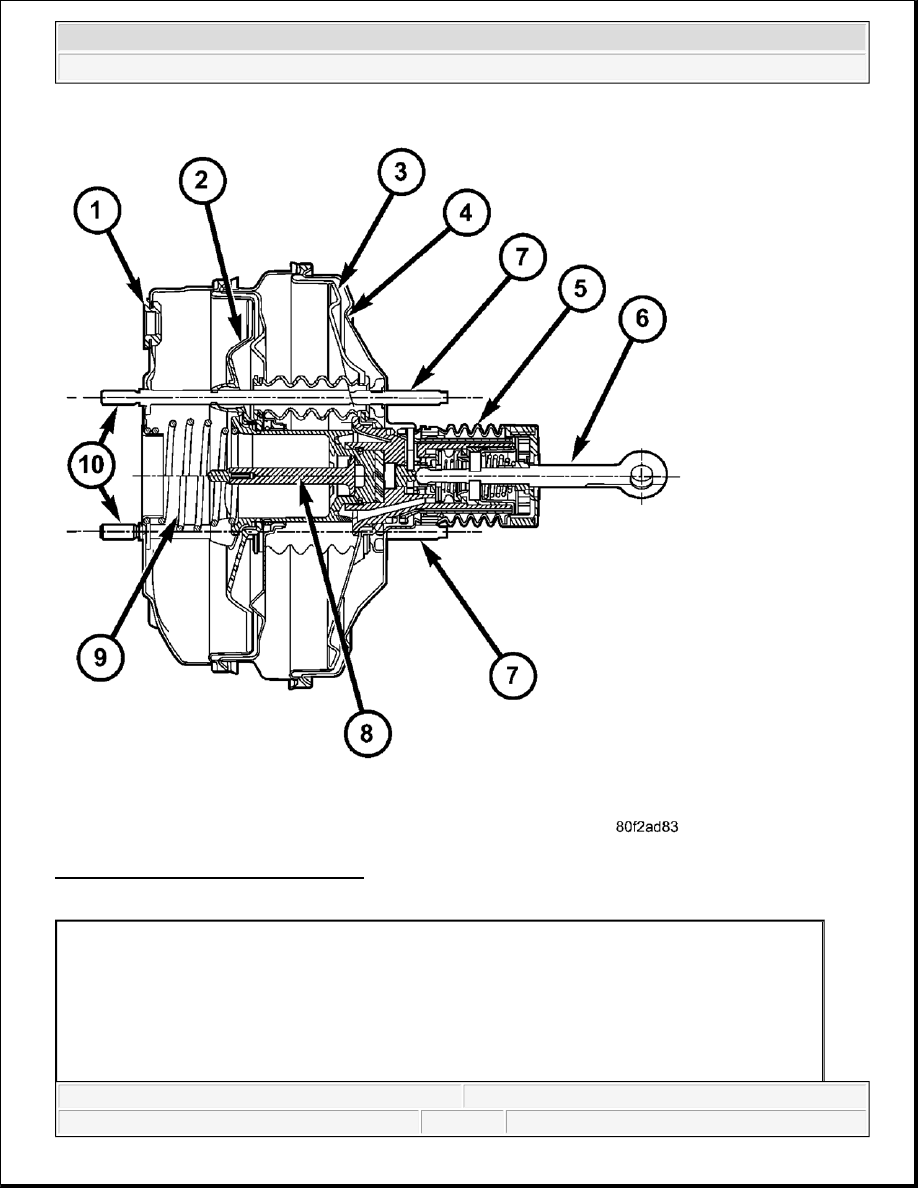

Fig. 50: Power Brake Booster Cut Away

Courtesy of CHRYSLER LLC

1 - VACUUM CHECK VALVE

2 - FRONT DIAPHRAGM

3 - REAR DIAPHRAGM

4 - HOUSING

5 - SEAL

6 - PRIMARY PUSH ROD (TO BRAKE PEDAL)

7 - BOOSTER MOUNTING STUDS

2007 Dodge Nitro R/T

2007 BRAKES Base - Service Information - Nitro