Dodge Nitro. Manual - part 110

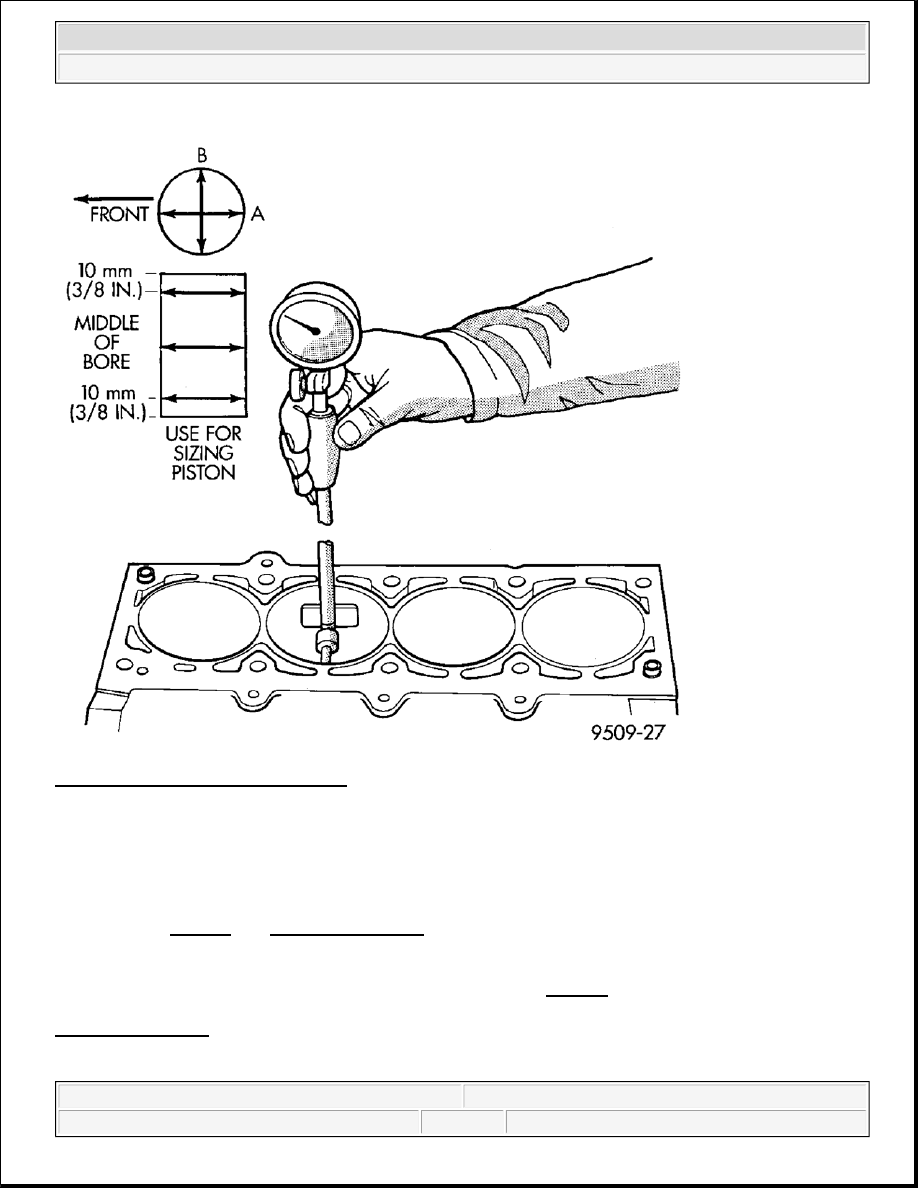

Fig. 175: Cylinder Bore Measurement

Courtesy of CHRYSLER LLC

The cylinder walls should be checked for out-of-round and taper with Tool C119 cylinder bore gauge, or

equivalent. See Fig. 175. See SPECIFICATIONS. If the cylinder walls are badly scuffed or scored, the

cylinder block should be replaced, and new pistons and rings fitted.

Measure the cylinder bore at three levels in directions A and B. See Fig. 175. Top measurement should be 10

mm (3/8 in.) down and bottom measurement should be 10 mm (3/8 in.) up from bottom of bore. See

SPECIFICATIONS.

BEARING -CONNECTING ROD

NOTE:

The cylinder bores should be measured at normal room temperature, 21°C (70°

F).

2007 Dodge Nitro R/T

2007 ENGINE 4.0L - Service Information - Nitro