Dodge Nitro. Manual - part 36

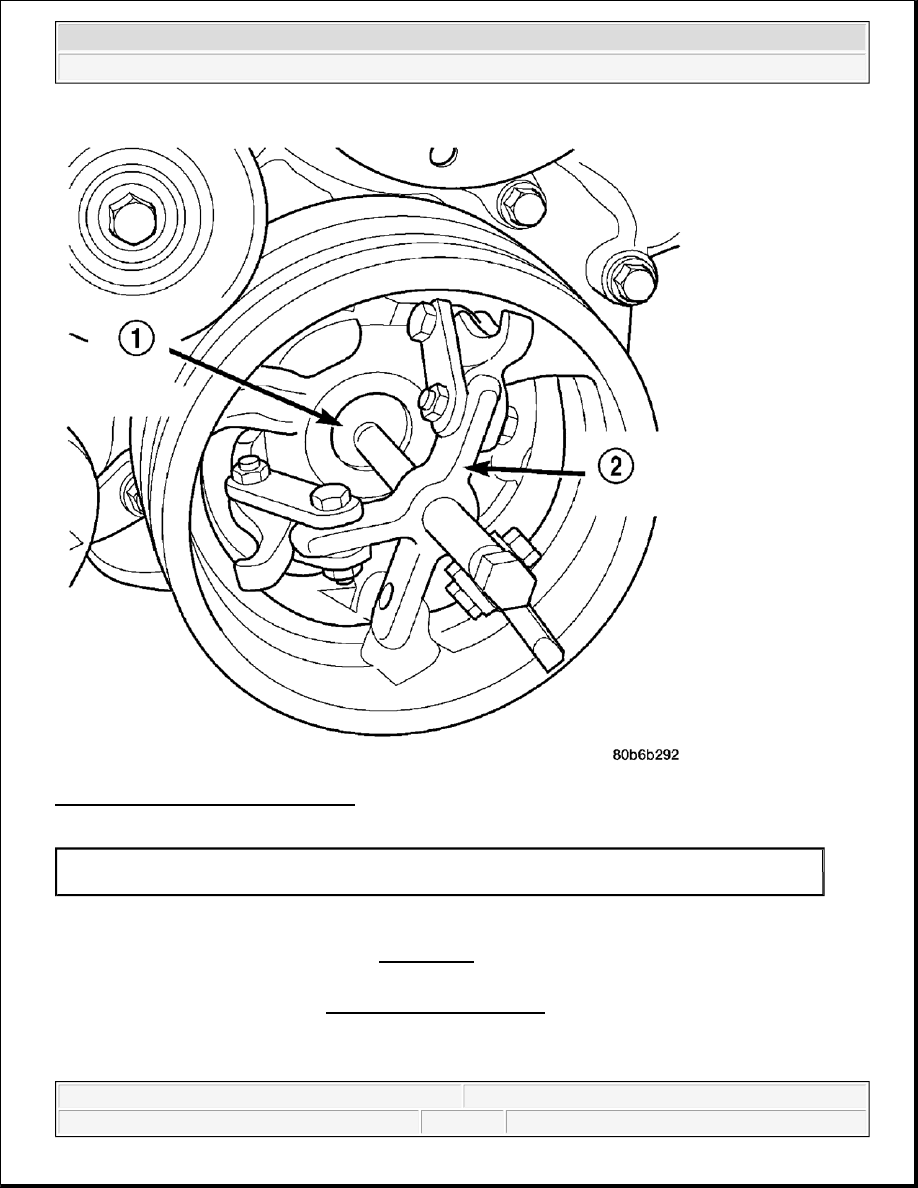

Fig. 105: Crankshaft Damper Removal

Courtesy of CHRYSLER LLC

1. Disconnect negative cable from battery.

2. Remove accessory drive belt. Refer to REMOVAL .

3. Remove A/C compressor mounting fasteners and set aside.

4. Drain cooling system. Refer to STANDARD PROCEDURE .

5. Remove upper radiator hose.

6. Disconnect electrical connector for fan mounted inside radiator shroud.

1 - SPECIAL TOOL 8513 I INSERT

2 - SPECIAL TOOL 1026

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro