Daewoo Musso. Manual - part 307

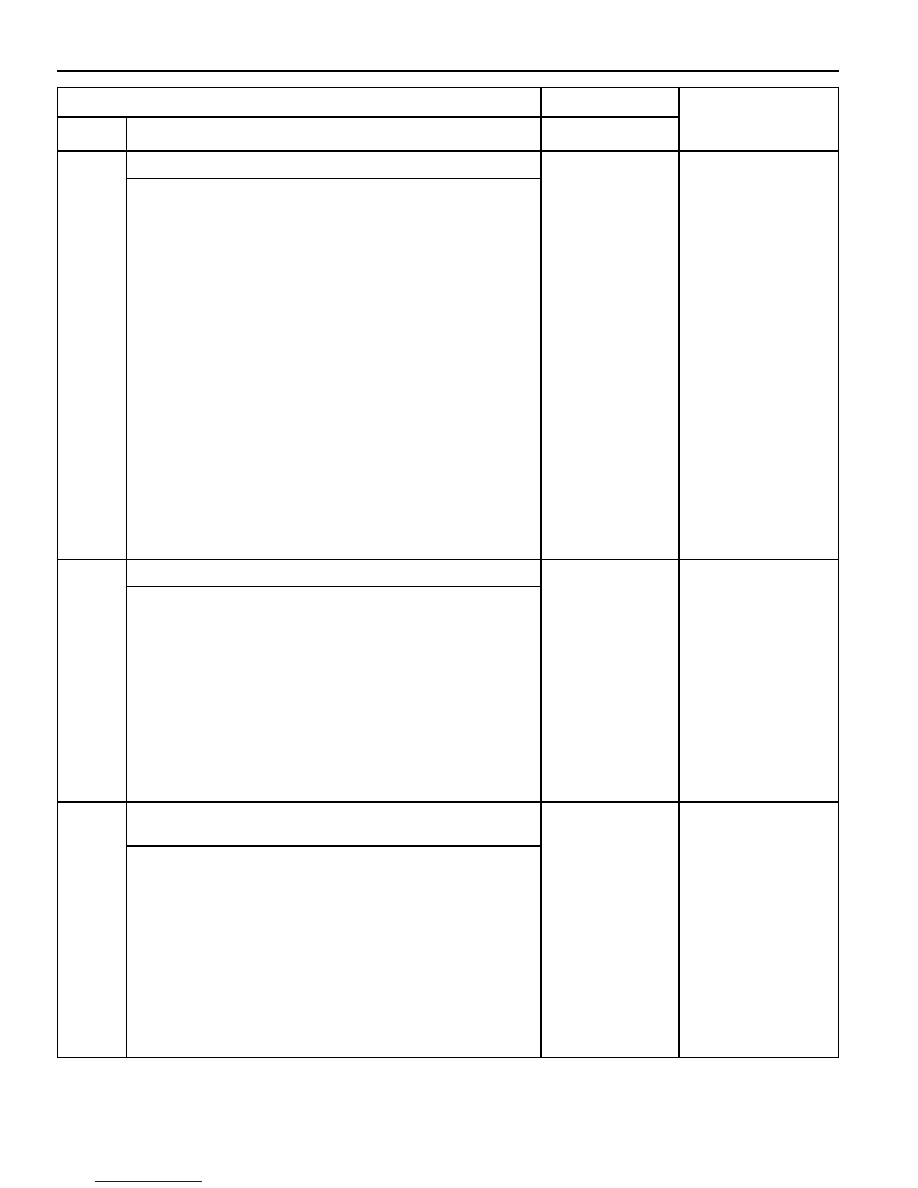

5D2-30 TRANSFER CASE (TOD)

Yes

No

Yes

No

Yes

No

E3

Yes

No

E4

Yes

No

E5

Test Stage / Contents

Result

Stage

Test Contents and Procedure

Specified Value

/Yes/No

Countermeasure

Check the wiring of shift motor whether it is shorted or not.

1. Turn off the ignition switch.

2. Detach the 30pin connector from TOD control unit

3. Perform short test between the wiring connector No.1/

No.14 and No.2/No.5.

- Is there resistance of 0

W

?

4. Perform the short test between No.1/No.14 Connector

and body, No2/No.15 connector and body.

- Is there resistance of 0

W

?

5. Execute E1 stage to check whether wiring is shorted

between Hi-Low motor and LOW-HI motor.

- Is the provided voltage proper ?

Check the resistance of shift motor

1. Turn off the ignition switch.

2. Measure the resistance between No.1/No.14 and No.2/

No.15 connector after detaching 30pin connector of TOD

control unit Or, check the resistance between No.G and

No.B after detaching motor connector of T/C side.

- Specified value

- Measured value is within specified range ?

Execute the test after detaching shift motor, when the fault

is not solved after executing E1~E4 stage.

1. Detach the motor connector from T/C.

2. Remove the shift motor.

3. Connect motor connector with the removed shift motor.

4. Operate the 4H/4L switch.

- Does motor rotate ?

Hi-Low motor and

Lo-Hi wiring are

shorted each other.

Repair or replace.

Perform E3-4 stage.

Related wiring is

shorted with ground.

Repair or replace.

Perform E3-5 stage.

Perform E4 stage.

Wiring is shorted.

Repair or replace.

The defective T/C or

perform E5 stage.

Replace the shift

motor.

Check and fix due to

the defective T/C

ass’y.

Replace the motor

or delete fault code

and rediagnosis

system.