Daewoo Musso. Manual - part 82

OM600 ENGINE MECHANICAL 1B3-35

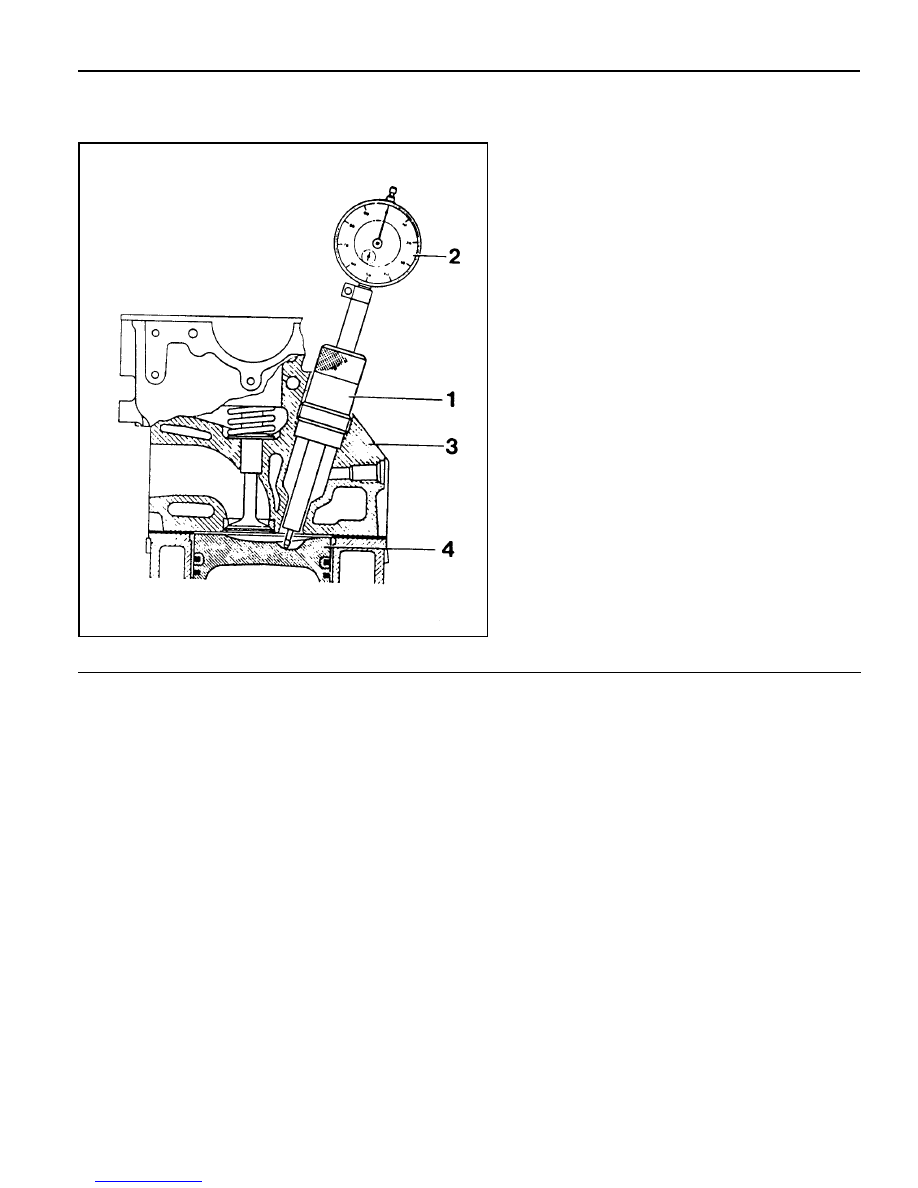

TDC (TDC SENSOR BRACKET) SETTING

Preceding Work : Removal of No.1 cylinder prechamber

1 Measuring Device

2 Dial Gauge

3 Cylinder Head

4 Piston ................................................ Set at TDC

Tools Service

001 589 32 21 00 Dial Gauge

601 589 07 21 00 Deqth Gauge

667 589 01 21 00 Fixing Device

Notice

l

The TDC sensor bracket must be adjusted in case of

followings.

l

When replacing the TDC sensor bracket.

l

When replacing the crankshaft, the hub or the vibration

damper.

l

When replacing or installing the timing case cover.

l

After engine overhauling.

*

If the cylinder head is removed, the measuring pin of the

dial gauge can be positioned on the piston crown.

This is done by placing the magnetic dial holder on the

mating surface of the crankcase.