Daewoo Matiz (2003 year). Manual - part 33

1F – 42 ENGINE CONTROLS

MAA1F070

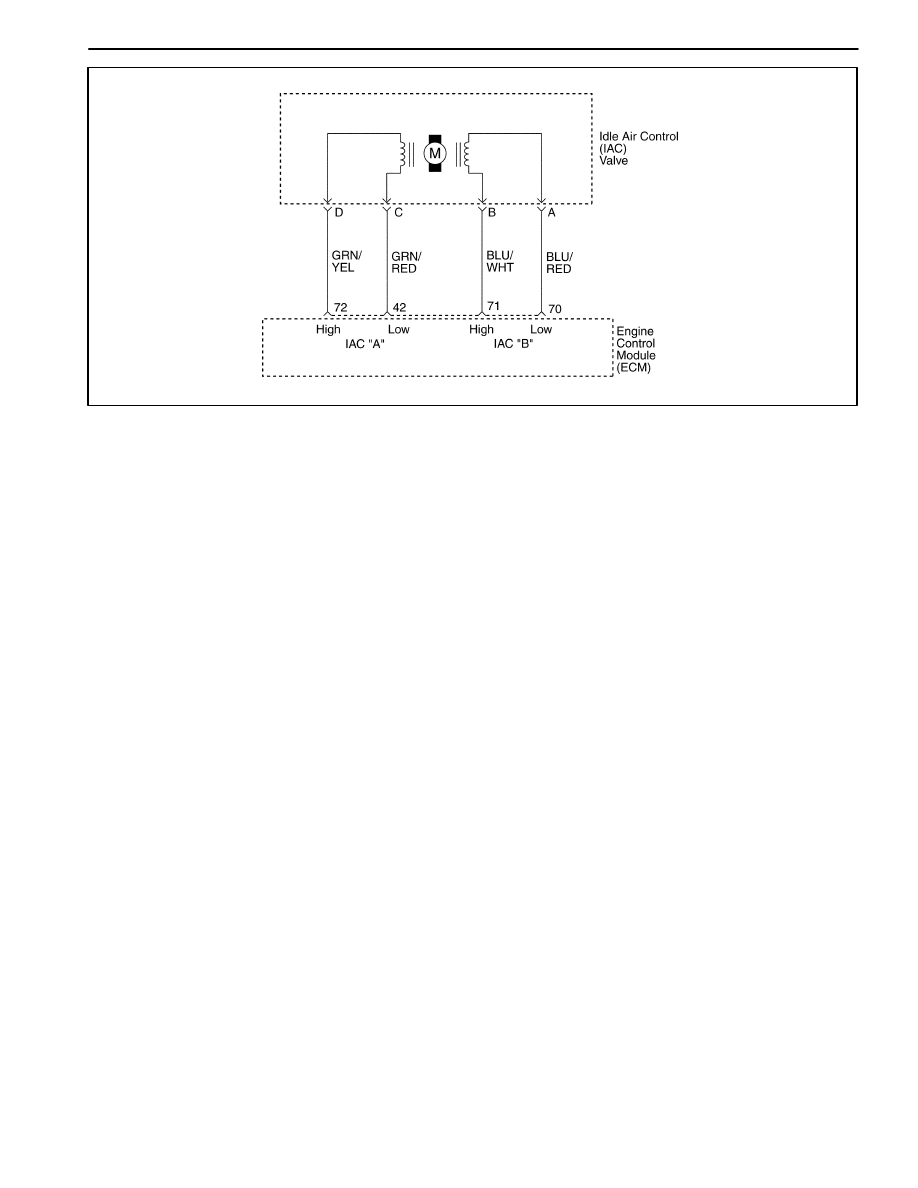

IDLE AIR CONTROL SYSTEM CHECK

Circuit Description

The Engine Control Module (ECM) controls the engine

idle speed with the Idle Air Control (IAC) valve. To in-

crease the idle speed, the ECM pulls the IAC pintle

away from its seat, allowing more air to pass by the

throttle body. To decrease the idle speed, it extends the

IAC valve pintle toward its seat, reducing bypass air

flow. A scan tool will read the ECM commands to the

IAC valve in counts. The higher counts indicate more air

bypass (higher idle). The lower counts indicate less air is

allowed to bypass (lower idle).

Diagnostic Aids

If the idle is too high, stop the engine. Fully extend the

Idle Air Control (IAC) valve with a IAC driver. Start the

engine. If the idle speed is above 950 rpm, locate and

repair the vacuum leak. Also, check for a binding throttle

plate or throttle linkage or an incorrect base idle setting.

Idle Air Control Valve Reset Procedure

Whenever the battery cable or the Engine Control Mod-

ule (ECM) connector or the ECM fuse EF6 is discon-

nected or replaced, the following idle learn procedure

must be performed:

1.

Turn the ignition ON for 5 seconds.

2.

Turn the ignition OFF for 10 seconds.

3.

Turn the ignition ON for 5 seconds.

4.

Start the engine in park/neutral.

5.

Allow the engine to run until the engine coolant is

above 85

_

C (185

_

F ).

6.

Turn the A/C ON for 10 seconds, if equipped.

7.

Turn the A/C OFF for 10 seconds, if equipped.

8.

If the vehicle is equipped with an automatic trans-

axle, apply the parking brake. While pressing the

brake pedal, place the transaxle in D (drive).

9.

Turn the A/C ON for 10 seconds, if equipped.

10. Turn the A/C OFF for 10 seconds, if equipped.

11. Turn the ignition OFF. The idle learn procedure is

complete.