Daewoo Korando. Manual - part 261

AUTOMATIC TRANSMISSION 5A-87

Transmission Case

To teardown the transmission case, proceed as follows:

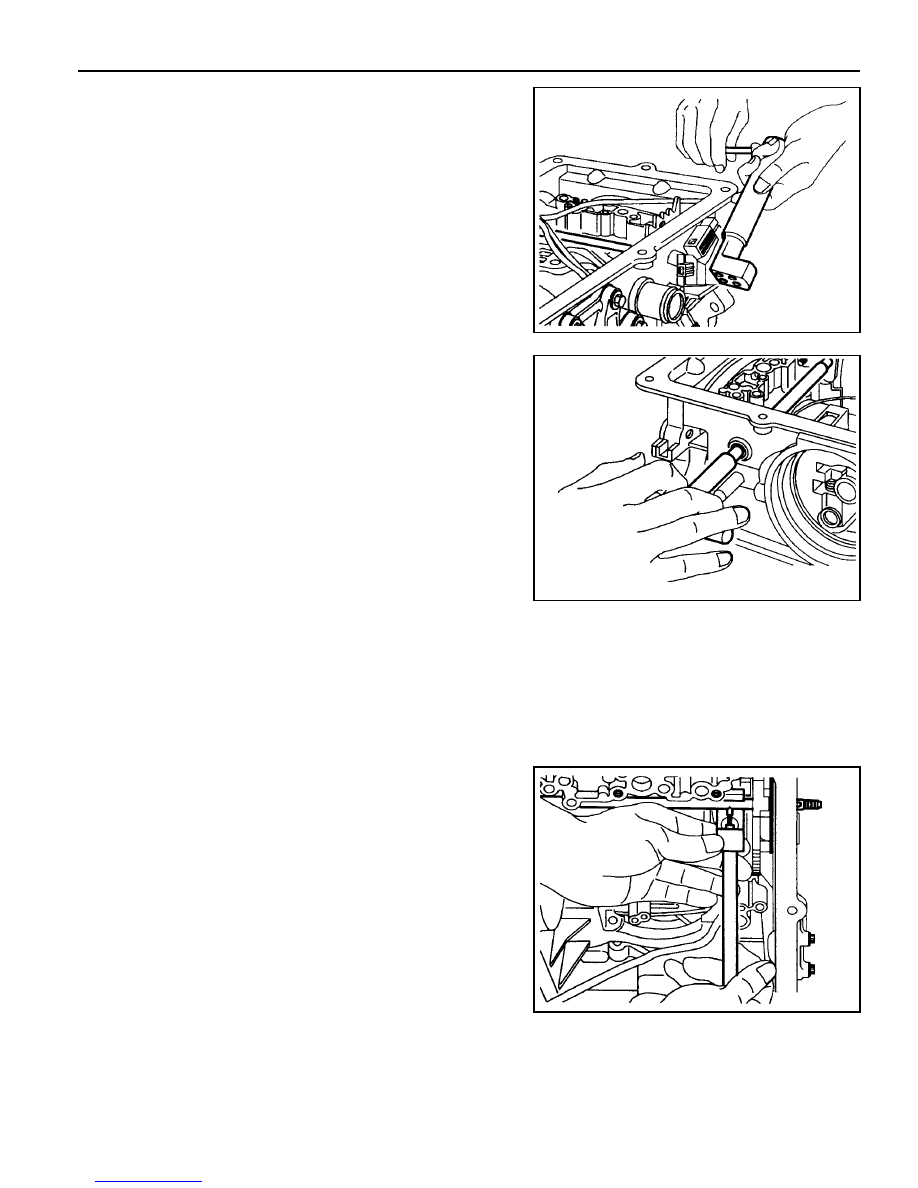

1. Remove the pin from the cross shaft inhibitor switch side

(4WD models) using tool No.0555-332942.

2. Remove the inhibitor switch from the case.

Remove the cross shaft seals with special tool No.0555-

331893.

3. Remove the circlip from the cross-shaft. Pull the shaft to

release the drive pin from the selector quadrant.

4. Using tool No. 0555-331897, press the pin from the cross-

shaft and withdraw the shaft from the case. Retrieve the

spring and pin

5. Remove the manual valve lever and the park rod.

6. Remove the 10 pin plug from the wiring loom bracket

adjacent to the inhibitor switch(RWD models),

7. Depress the tangs and withdraw the 10 pin connector from

the case. Remove the loom assembly.