Daewoo Korando. Manual - part 250

AUTOMATIC TRANSMISSION 5A-43

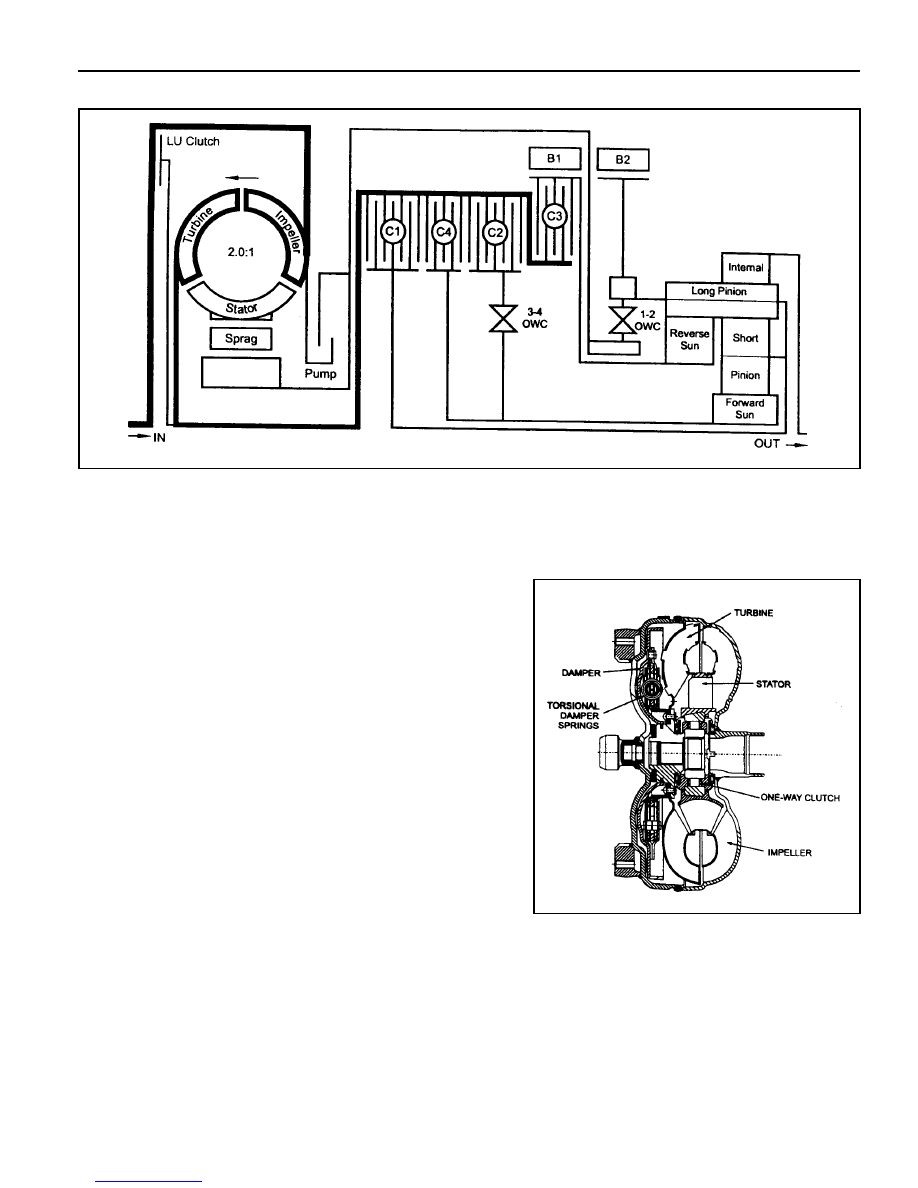

Figure 4.1 - Power Flow Diagram

TORQUE CONVERTER

The torque converter (refer figure 4.2) consists of a turbine,

stator pump, impeller and a lock-up damper and piston

assembly. As in conventional torque converters, the impeller is

attached to the converter cover, the turbine is splined to the

input shaft and the stator is mounted on the pump housing via

a one way clutch (sprag).

The addition of the damper and piston assembly enables the

torque converter to ‘lock-up’ under favourable conditions. Lock-

up is only permitted to occur in third and fourth gears under

specified throttle and road speed conditions.

Lock-up is achieved by applying hydraulic pressure to the

damper and piston assembly which couples the turbine to the

converter cover, locking-up the converter and eliminating

unwanted slippage. Whenever lock-up occurs, improved fuel

consumption is achieved. Torsional damper springs are

provided in the damper and piston assembly to absorb any

engine torque fluctuations during lock-up.

Figure 4.2 - Torque Converter Cross Section