Daewoo Korando. Manual - part 212

2E-2 TIRES AND WHEELS

DIAGNOSIS

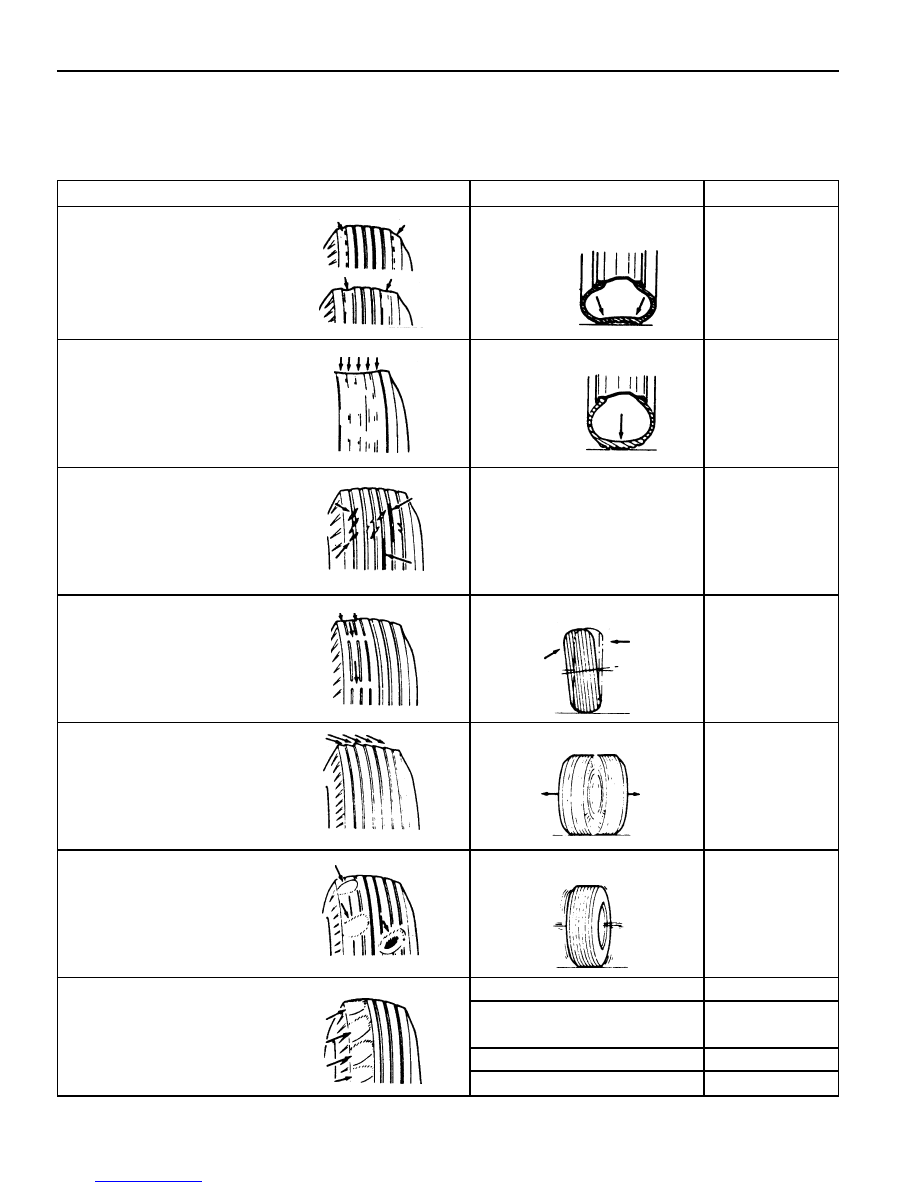

WEAR PATTERN DIAGNOSIS

Wear Pattern

Possible Cause

Remedy

Wear on Both Tread Shoulders

Under Inflation

Wear on Tread Center

Over Inflation

Tread Torn Out

Under Inflation

One-sided Tread Wear

Incorrect Camber or Toe-in

Feather Edging of Tread

Incorrect Toe-in

Spotty Tread Wear

Out of Wheel Balance

Spotty Wear-wear Localized on

Shoulder Sections

Out of Wheel Balance

Play in Hub Bearings

Play in Ball Joint

Defective Shock Absorber

W05-40-003

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Check play

Adjust preload

Check

Check