Daewoo Korando. Manual - part 186

1F3-28 OM600 ENGINE CONTROLS

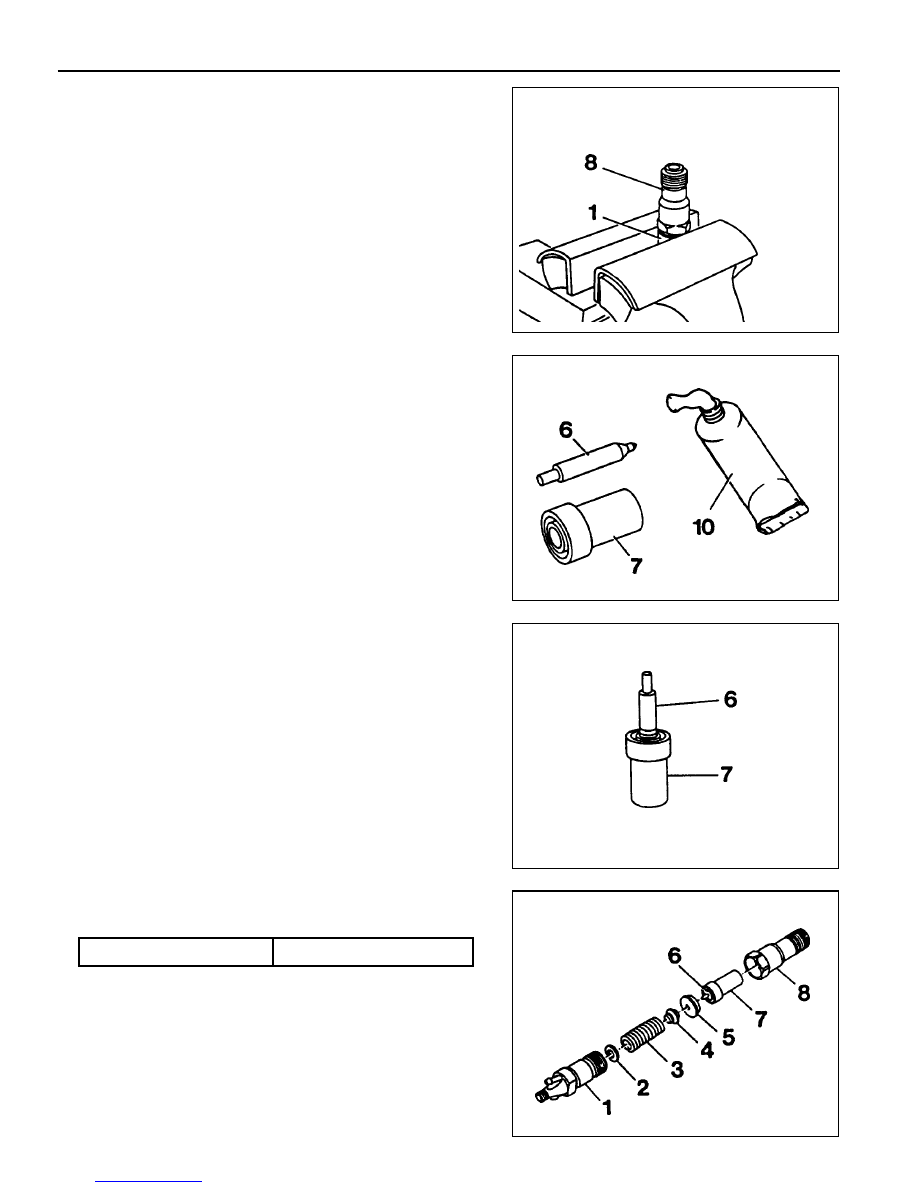

Tools Required

001 589 65 09 00 Socket Wrench Insert

000 589 00 68 00 Cleaning Set

Repair Procedure

1. Clamp the nozzle holder (1) in a vice and remove the nozzle

tensioning nut (8).

Notice

Use protective jaws for clamping.

2. Disassemble the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Clean the nozzle needle (6) and nozzle body (7) with an

abradant.

4. Clean the nozzle seat with cleaning cutter.

Cleaning Set 000 589 00 68 00

5. Immerse nozzle needle (6) and nozzle body (7) in filtered

diesel fuel. When the nozzle body is held vertical, the weight

of the nozzle needle must cause it to slide down toward the

nozzle needle seat.

6. Assemble the injection nozzle so that the tip of the thrust

(4) pin is facing toward the nozzle holder.

Tightening Torque

80 Nm

Notice

Nozzle needle (6) and nozzle body (7) should always be

replaced as a pair.