DAF CF65, CF75, CF85 Series . Manual - part 953

©

200423

3-5

Inspection and adjustment

STEERING GEAR, GENERAL

ΧΦ65/75/85 series

7

2

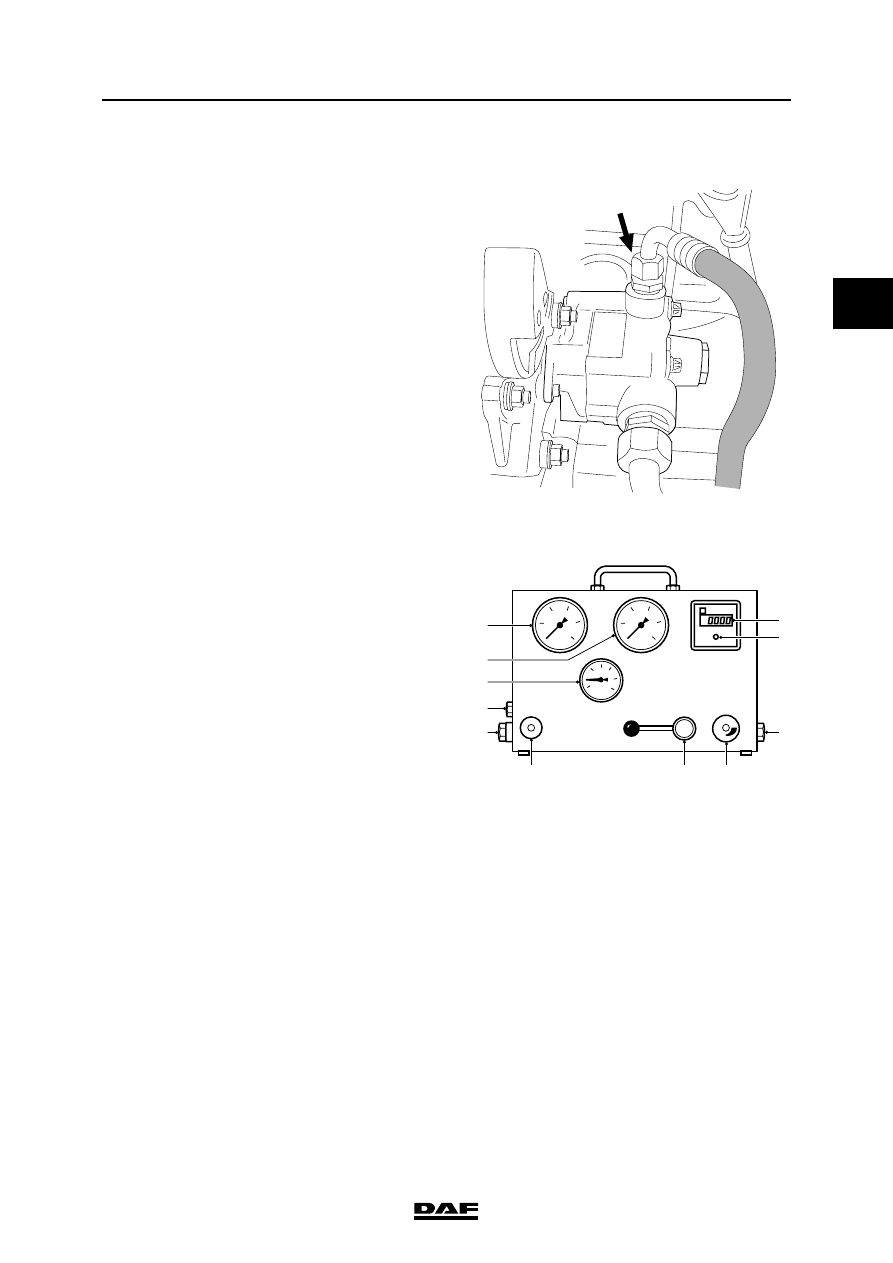

Items requiring special attention when

connecting the test case

1.

Clean the delivery line connection that is

going to be disconnected.

2.

Check the steering box attachment.

3.

Check the hydraulic central position.

4.

Place proper turning plates under the

vehicle's steerable wheels.

Block the vehicle so that it cannot

slide off the jack or the turning

plates.

5.

With an EMAS-controlled trailing axle

remove the fuses from the EMAS system.

Connecting the test case

1.

Check whether the non-return valve (5) of

the 'Servotest 550' is completely closed, the

cock (4) has been fully opened and the

pressure adjusting device (6) of the

pressure-limiting valve is set in accordance

with the maximum system pressure.

Only use couplings and lines which

are suited to the maximum system

pressure.

S7 00 585

}

50

100

150

200

250

5

10

15

20

25

9

7

8

2

4

6

5

10

11

1

3

S7 00 020

}