DAF CF65, CF75, CF85 Series . Manual - part 471

©

200324

4-11

Removal and installation

XE ENGINE FUEL SYSTEM

CF65/75/85 series

4

8

6.

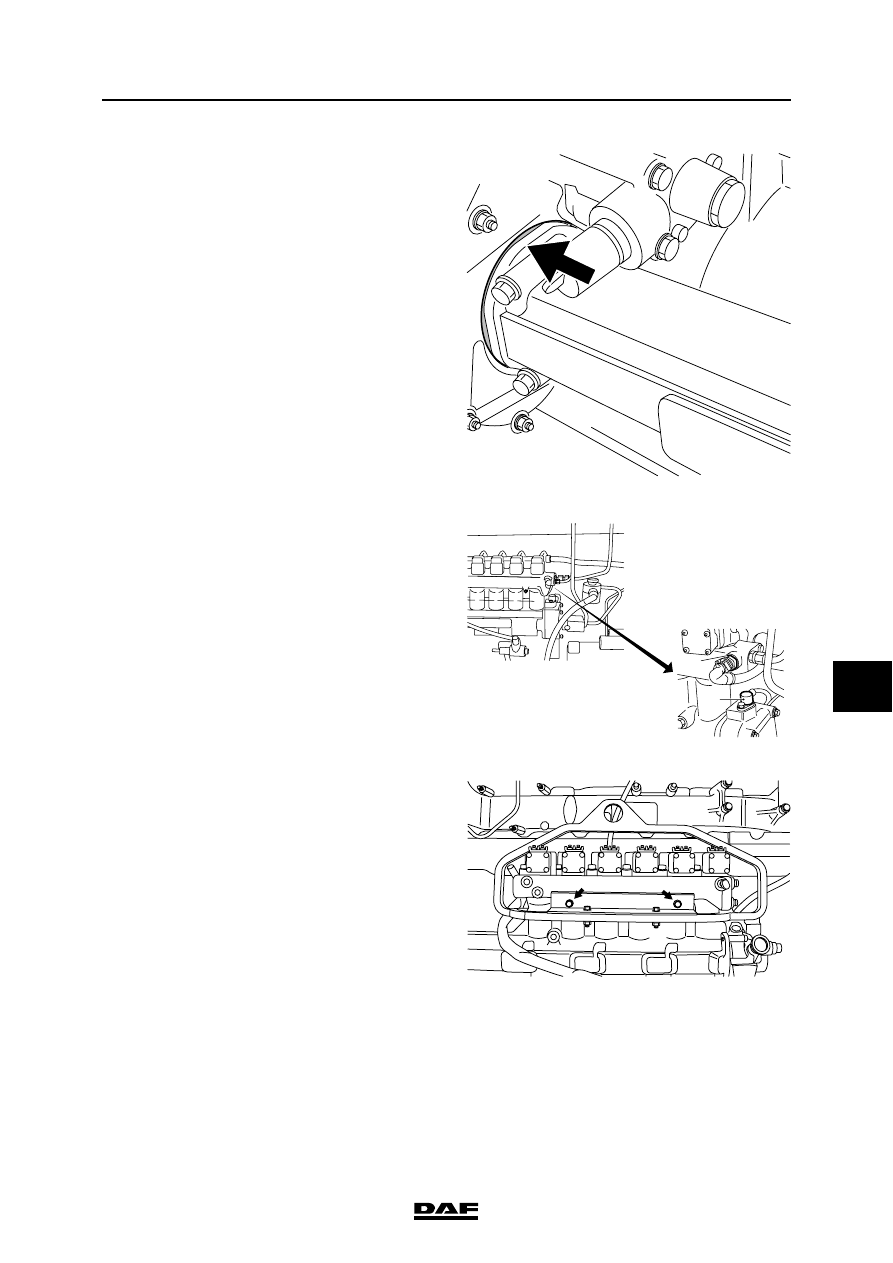

Remove the timing gear seal by tapping it out

of the timing gear case in the driving

direction.

7.

Remove the electrical connections from the

pump units.

8.

Remove the fuel pipes from the pump

housing.

9.

Remove the pressure relief valve from the

pump housing.

10. Let the fuel leak from the pump housing.

11. Remove the fuel pipes from the fuel lift pump.

12. Remove the fuel injection pipes and plug the

pump units and injectors so that no dirt can

enter the system.

13. Remove the connector from the fuel

temperature sensor (1) (if fitted on the pump

housing).

14. Remove the camshaft position sensor (2).

}

Due to the weight of the pump

housing, use the special tool.

15. Fit the lifting gear (DAF no. 1329499) to the

pump housing and tighten the bolts (A).

16. Remove the attachment bolts of the pump

housing and lift the pump housing off the

dowel pins on the engine block using the

lifting gear.

M200728

i 400529

2

1

i400601

A

A